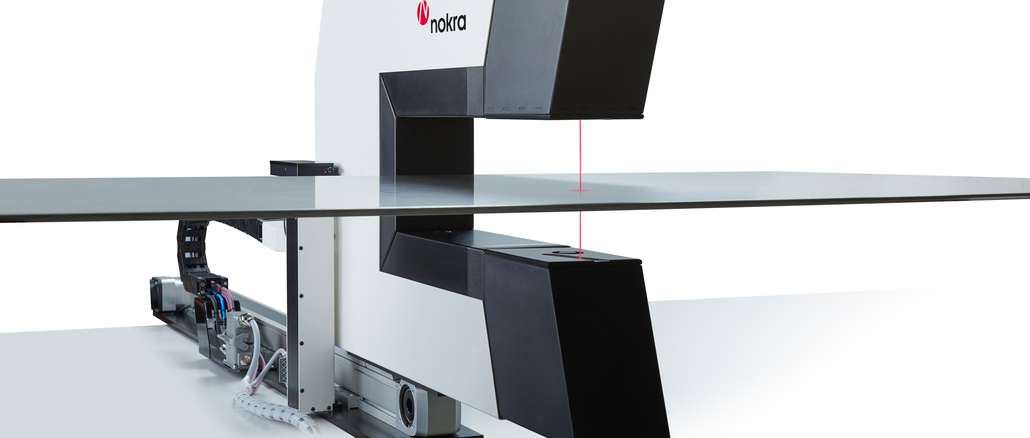

The new laser-optical thickness measuring system “alpha.ti 5.0” from nokra makes it possible for the first time to precisely measure the thickness of cold-rolled strips up to 2,000 mm wide without having to frequently check the adjustment during production. This makes it the first system in the world that is suitable for measurement on wide bands, even at highly fluctuating ambient temperatures.

Laser-optical thickness measurement has increasingly prevailed over X-ray systems on strip processing lines. However, with wide belts and correspondingly large leg lengths of the C-frame, this method reached its limits: The mechanical and thermo-mechanical influences on the stirrup would be so great that very frequent reference runs would be necessary.

© Nokra

Therefore Nokra has developed an active deformation compensation for its new laser-optical thickness measuring system “alpha.ti 5.0” and applied for a patent. In contrast to systems in which the deformation of the C-frame is merely minimized, in the new system Nokra continuously measures the instantaneous distance between the sensors to an accuracy of ± 0.5 µm and uses it for automatic compensation of the measured values.

Initial results with a zero series system confirm that it maintains the specified measurement accuracy even with pronounced day-night temperature cycles over a period of several days. The system is currently undergoing extensive practical tests at a customer’s plant.

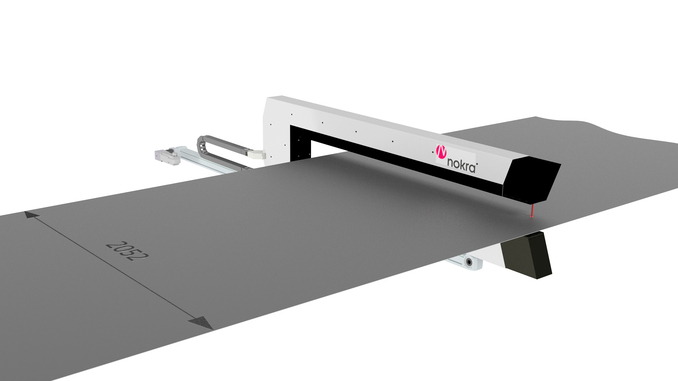

With the active deformation compensation Nokra realizes C-frame with a leg length up to 2 m. The systems are suitable for narrow strips as well as for very wide strips, where the complete thickness transverse profile is measured traversing.

Reference runs only need to be carried out very rarely, for example during commissioning or planned maintenance shutdowns. This is particularly advantageous for endless belts, for example in Conti plants, because there are no more unmeasured, blind sections in the running direction of the belt.

The technology behind laser optical thickness measurement

In the laser-based measurement, the thickness of the strip is calculated from the results of the distance measurement of the two triangulation sensors arranged above and below the strip and the distance between the sensors. This plays a decisive role in addition to the measuring accuracy of the distance measurement of the two sensors. In particular, fluctuations in the ambient temperature can lead to thermal deformation of the measuring yoke and thus to drift. By continuously measuring the distance between the sensors, Nokra eliminates this effect.

For the infrequent reference runs, a small referencing unit is used, which is stationary outside the belt run next to the C-frame and is swivelled into the beam path as required. It contains three commercial gauge blocks. For proof of measuring equipment capability, for example during audits, the customer can equip the unit with his own gauge blocks.

About Nokra

Nokra Optische Prüftechnik und Automation GmbH was founded in 1991 as a spin-off of the Fraunhofer Institutes for Laser Technology (ILT) and Production Technology (IPT) in Aachen. As a medium-sized company, Nokra develops, produces and sells laser measurement systems worldwide for the automatic inline inspection of geometric characteristics of products in the metal, automotive and glass industries. Test objects are rolled products in the steel, aluminium and non-ferrous metal industry, large tubes as well as components of vehicles, such as camshafts or crankshafts, axle carriers and windscreens.

Web:

www.nokra.de