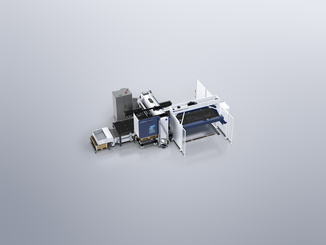

At Blechexpo, Trumpf presented the Flex Cell mobile bending cell in combination with the TecZone Bend software.

The Flex Cell is the fastest mobile bending cell from Trumpf. Users can connect it to the highly productive TruBend 7050 bending machine in just a few simple steps and then have the bending machine work through automatically.

The TecZone Bend software extension reduces the programming effort for the bending machine and the robot to seconds, making automation worthwhile even for new components with very small batch sizes. In addition, the bending cell can be programmed “offline” with TecZone Bend, for example from the office. Meanwhile, the mobile bending cell can continue to produce parts. This increases productivity even further.

Trumpf Product Manager Wolfgang Radler: “With TecZone Bend, the Flex Cell is not only the fastest, but also the most flexible mobile bending cell from Trumpf. Thanks to the software, users can deploy it quickly and easily for components of all kinds – without any loss of productivity or time-consuming programming.” In addition, the previous limitation of four bends has been completely eliminated. This means that the FlexCell is now also suitable for complex components and assemblies.

© Trumpf

Software programs bending machine and robot in one step

With most mobile bending cells on the market, users have to program the bending machine and the robot separately. This is complex and time-consuming. With the Flex Cell with TecZone Bend, the software creates both programs automatically and simultaneously – including collision monitoring in real time. All users have to do is upload the CAD data of their component to the software and have the program created automatically. In addition, employees without in-depth programming knowledge can also set up the Flex Cell.

Efficient even for small quantities

The Flex Cell itself is suitable for components with a format of up to 600 x 400 millimetres and processes sheet thicknesses of up to six millimetres. In combination with the TruBend 7050, the machine is suitable for all companies that want to increase their productivity through automation or suffer from a shortage of skilled workers.

Companies with a fluctuating order situation that produce small and simple components will now also benefit significantly. They can use the solution to absorb order peaks by having the mobile bending cell automatically take on additional shifts.

Older Flex Cell models can be retrofitted with the software.

Trumpf and Stopa expand partnership for smart factory solutions

The high-tech company Trumpf and one of the leading manufacturers of automated storage systems, Stopa, want to further expand their successful partnership. The two companies have now publicly announced an agreement to this effect in the run-up to Blechexpo.

The aim is to further strengthen Trumpf’s role as a provider of innovative smart factory solutions. With this in mind, Trumpf has increased its stake in Stopa Anlagenbau GmbH from 25.1 percent to 74.9 percent.

Reduce non-productive time

Stopa supplies automated storage systems for Trumpf’s Smart Factory solutions, among other things. Customers can use it to automate the loading and unloading of their machines and to network them logistically. Productivity in production increases as unproductive downtimes are greatly reduced.

Till Küppers, COO Trumpf Machine Tools: “With this step, we want to put our long-standing collaboration with Stopa on a new footing. Our aim is to further develop smart factory solutions together and offer our customers an even broader range of efficient, sustainable and productivity-enhancing options.”

Simplified production planning and control

Storage systems from Stopa can be optimally adapted to the growing challenges of modern smart factory production or integrated into existing factories. Automation in conjunction with Trumpf’s Oseon software offers particular advantages, allowing production planning and control to be simplified even further, right up to fully automated operation of sheet metal production.

“After almost 40 years of successful partnership with Trumpf in the automation of production, we are now looking forward to taking the next step together and working even more closely in the future,” says Michael Stolzer, partner and Managing Director of Stopa Anlagenbau GmbH.

Stopa was founded in Achern, Germany, in 1963 and employs more than 300 people. The company specializes in automated storage systems for sheet metal and long goods.

Web:

www.trumpf.com