Bombed-out cities, a destroyed infrastructure and now also the cold: the people in Ukraine urgently need help. With a special campaign, KUIPERS technologies GmbH brings a little warmth to the country: field stoves, for heating and cooking. They are manufactured with fully automated machines from TRUMPF.

The Ukrainian civilian is right on the front line. Around him only destruction: no houses, no shelters. And it is bitterly cold. He has just learned that field ovens will soon be delivered. They can be heated with wood and have space for a cooking pot to heat water or food. He is grateful to the team of the charity “Helping Hands” and he is looking forward to a little warmth in these days of cold.

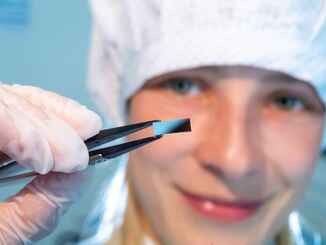

© Trumpf

Fast it must go

The idea to deliver stoves to Ukraine came from Heiner Meiners and Markus Vähning from the aid organization “Helping Hands” in Lathen in Emsland. They have experienced the unbearable situation of the people on the ground and it was clear to them that fast help is needed. They attract donors who would like to support their project financially and then contact Michael Kuipers, Managing Director of KUIPERS Technologies GmbH, based in neighboring Meppen. His company specializes in the series production of assemblies and supplies international customers from numerous industries.

“Of course, we immediately pledged our support,” Kuipers recounts. “The tight schedule – designing and producing 760 ovens in just under three weeks – was a huge challenge. On the other hand, our automated production offers the best conditions for such a project at record speed.” There is also support from the KUIPERS workforce: the employees are happy to work overtime for the relief campaign.

Automation brings speed

First, Karsten Hanenkamp, plant manager at KUIPERS, sits down with employees from the design department. “The specification was that the furnace would provide sufficient heating capacity and be quite easy to assemble,” he says. In addition, the field oven should be easy to transport and not too heavy. A whole lot of requirements, in other words. It was also clear: “Due to the tight schedule, only automated production of all parts was an option,” says Hanenkamp.

A fortunate coincidence was that only recently the new TruBend Center 7020 swivel bending machine from TRUMPF was put into operation at KUIPERS. “We wanted to produce the largest possible firing chamber for our kiln, and of course we wanted to do it automatically. This is not feasible with a conventional bending machine. Only the TruBend Center 7020 is capable of doing this,” explains Hanenkamp, and Michael Kuipers adds, “We took full advantage of the machine’s potential and estimated a diameter of 333 millimeters for the firing chamber. A whole lot of wood will fit in there.” The loading and unloading robot connected to the TruBend Center 7020 also saves time: Its grippers stack the finished bent parts directly onto pallets, which then go to the welding shop for further processing.

© Trumpf

Simple and ingenious

Within just 48 hours, the designers developed and built a prototype of the furnace. “We fired it to make sure nothing warped,” Michael Kuipers tells us. “And after a few touch-ups, it went straight into production.”

The field oven consists of a total of 22 parts. To assemble the individual parts, the designers have given the oven door handle an ingenious secondary function: It functions as a wrench that can be used to fasten the few screws that hold the oven parts together. Illustrated assembly instructions make assembly a breeze. “All the individual parts lie in the sealed firing chamber to form a set that can be easily transported with the help of two attached carrying handles,” Kuipers describes.

Maybe just the beginning

The team at KUIPERS met the sporting deadline with the help of a lot of dedication and automated machinery, producing 760 field ovens in just over three weeks. “When they are standing in our yard like this, it looks like a lot. But we are aware that in view of the many freezing people in Ukraine, they are just a drop in the bucket,” says Michael Kuipers. At the end of January, the Helping Hands organization brings the stoves on trucks to the war zone. And Kuipers is certain that he and his team will produce more ovens if donors can be found to contribute financially to the project.

Web:

www.trumpf.com