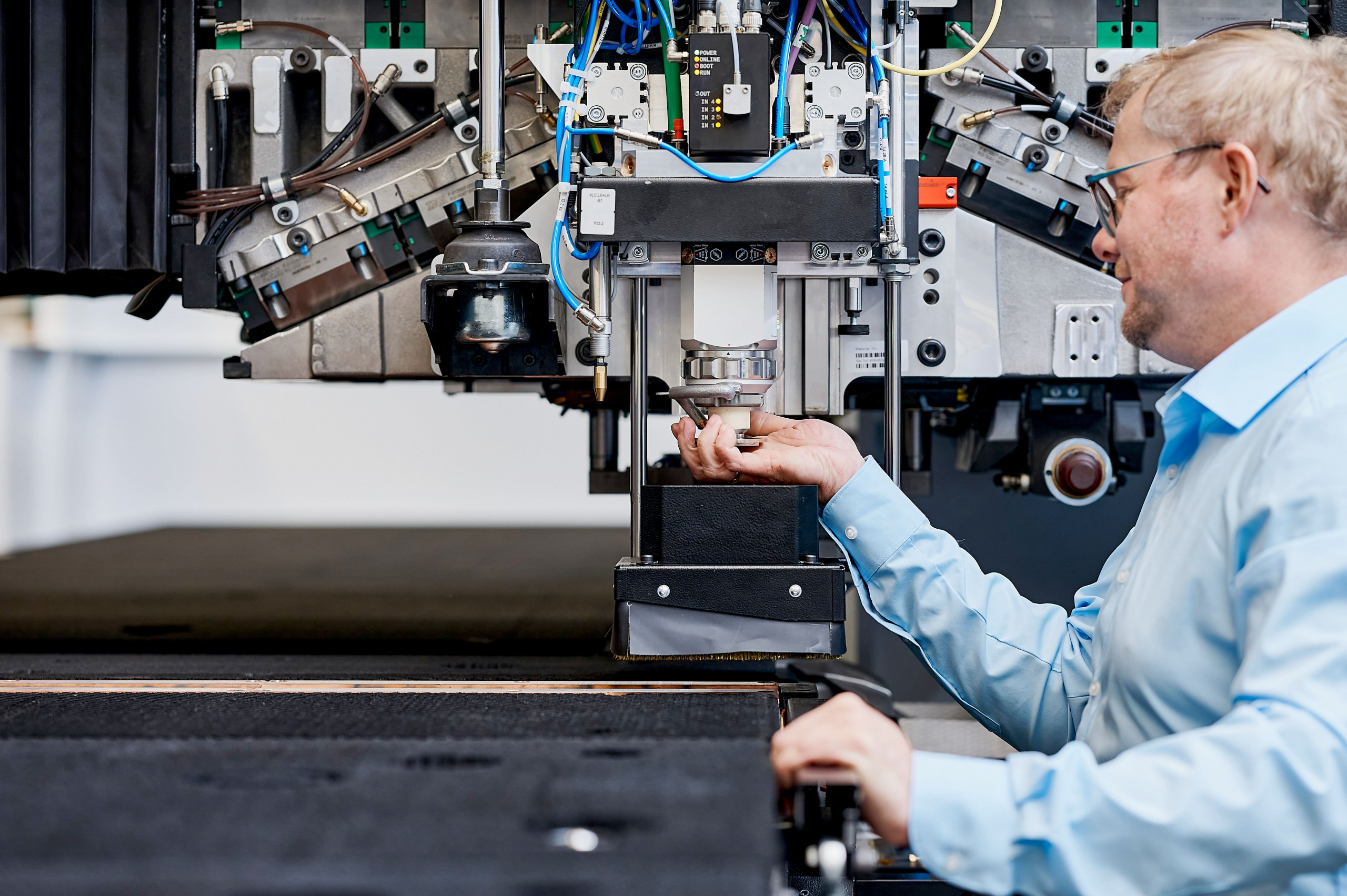

The “Runability Guide” software uses artificial intelligence (AI) to support the user when manually running in new jobs on the fully automated TruMatic 5000 punch laser machine.

At its in-house trade fair Intech, Trumpf is presenting the “Runability Guide”, a first version of a new AI solution that enables users to run in the TruMatic 5000 punch laser machine more quickly and easily. Until now, production employees had to test the program on the machine individually every time they wanted to produce a new order with previously unknown geometries or materials. This results in unproductive downtimes, especially with fully automated machines that produce many different parts.

The AI-supported “Runability Guide” software from Trumpf enables users to avoid downtimes of up to 20 minutes when starting up the system. The solution uses different evaluation models to show the employee for each order whether the TruMatic 5000 can produce the components directly or whether manual intervention is to be expected.

“Our Runability Guide provides companies with productivity and competitive advantages. Not only do they save time, but they can also use their staff’s expertise for value-adding tasks or train new staff,” promises Jonathan Eberle, Project Manager in the Development department at Trumpf.

Software recommends which parts are suitable for the night shift

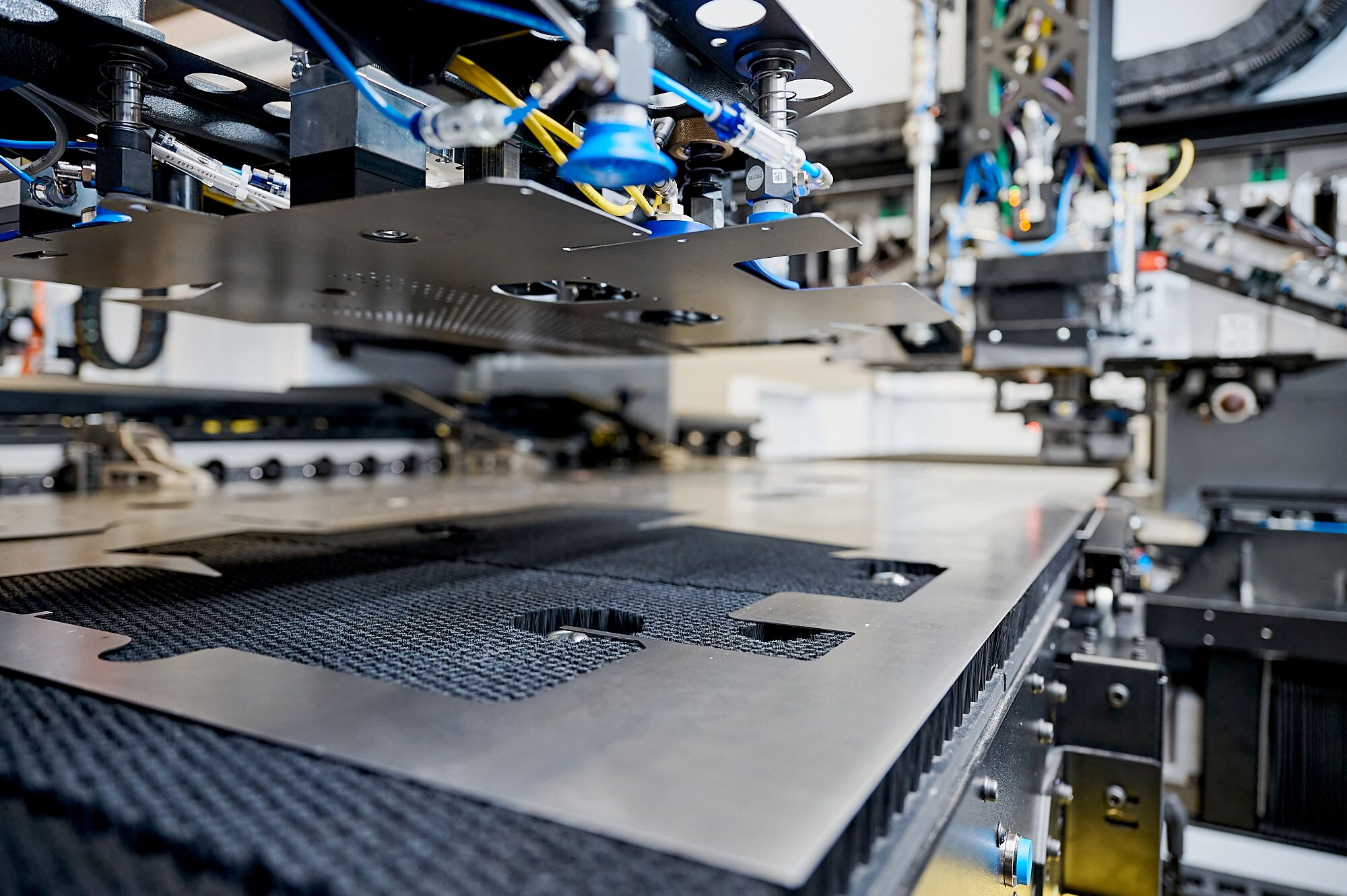

When a machine produces parts automatically, errors can occur. For example, the automation may not be able to remove the part correctly from the remaining grid due to jamming. It comes to a standstill and a production employee has to manually remove the part from the machine room and restart the machine. Whether the component can be removed reliably depends, among other things, on the geometry of the part and the position of the grippers on the workpiece.

When a machine produces parts automatically, errors can occur. For example, the automation may not be able to remove the part correctly from the remaining grid due to jamming. It comes to a standstill and a production employee has to manually remove the part from the machine room and restart the machine. Whether the component can be removed reliably depends, among other things, on the geometry of the part and the position of the grippers on the workpiece.

The Runability Guide now checks, for example, how much the component bends during removal due to gravity and could cause jamming. If a predefined limit value is exceeded, the software marks the corresponding point in red. This enables the employee to recognize immediately which components of an order need to be readjusted. In addition to details of possible errors, the software also recommends which jobs are suitable for the night shift. “Normally, an experienced expert would have to assess the geometry of the component, the material, the sheet thickness and other factors. Our solution makes this decision with the help of AI and learns in the future,” explains Eberle.

Valuation takes place within a few seconds

The Runability Guide from Trumpf uses various models to determine the complexity of the component. To this end, the Trumpf developers continuously make the knowledge of experts from production available in the cloud. In addition, the software carries out the evaluation using physical simulations and AI to identify potential challenges in the process steps. Finally, the solution works with real machine data from TruMatic 5000 users, which allows conclusions to be drawn about sources of error during processing. “Once all the models have checked the order, the tool issues its forecast. Traditional physical simulation models would take up to an hour to make a forecast, depending on the component. With AI, we can significantly speed up this process and make it usable for our customers practically in real time,” explains Eberle.

Machine data from users needed to further improve the software

Companies that purchase a TruMatic 5000 from Trumpf receive the Runability Guide as part of the delivery. The prerequisite for this is that they provide Trumpf with the machine data. “Unlike with conventional software, users start with a small range of functions. With their data from production, they then help us to continuously improve the solution. This in turn benefits the customer. New development approaches like this are needed to create added value with data and AI in production,” concludes Eberle.

Web:

www.trumpf.com