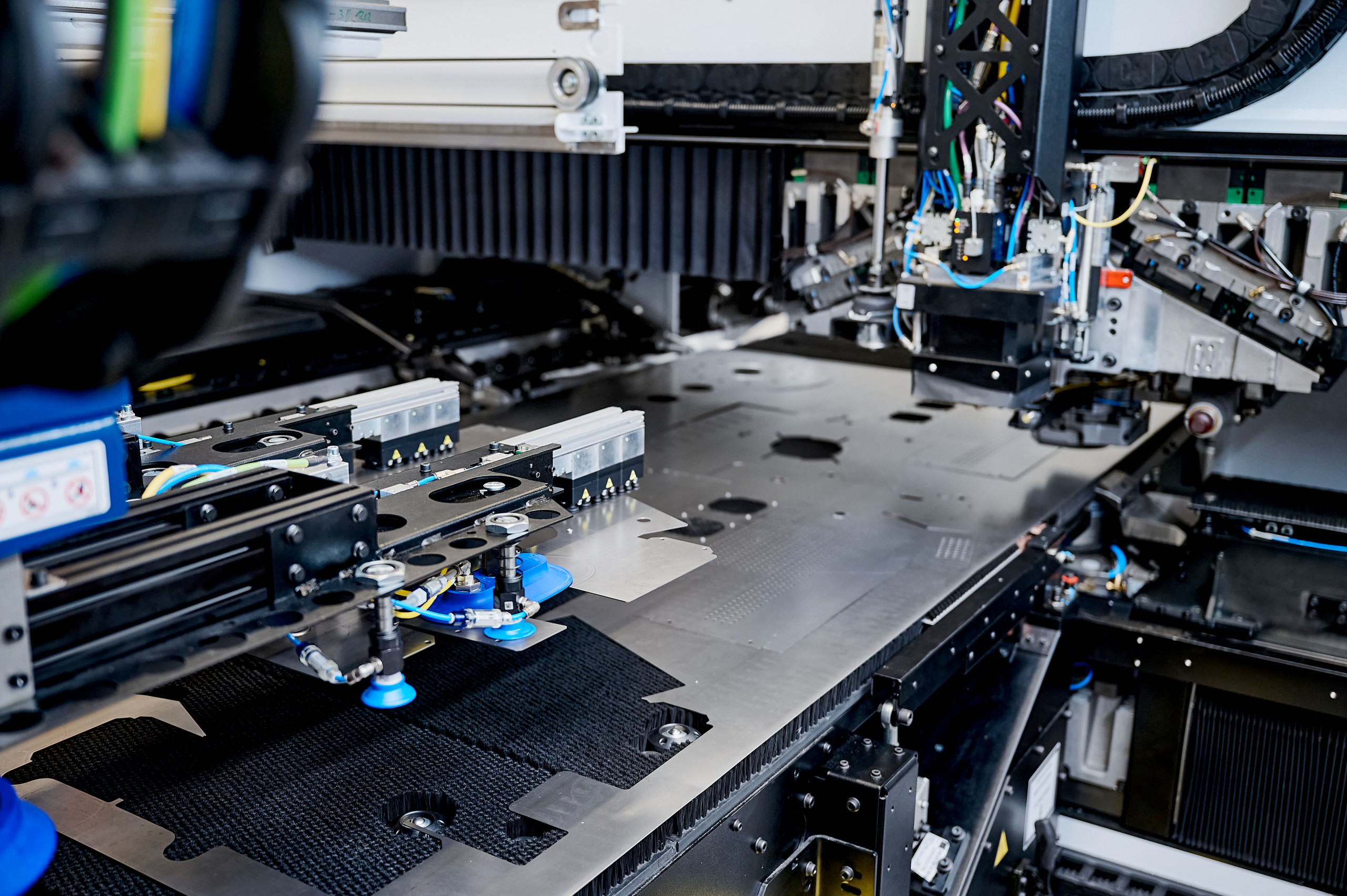

At Blechexpo, Trumpf is launching the TruMatic 5000 manufacturing cell with the new SheetMaster. Users can use the solution to fully automate laser cutting, punching and forming of their components. The new SheetMaster enables a fully automatic material flow in the production cell – from loading and unloading the machine to discharging the processed parts.

© Trumpf

“With the TruMatic 5000, Trumpf once again proves its market-leading position in networked manufacturing. The solution can be seamlessly integrated into a self-sufficient smart factory. This enables efficiency advantages along the entire process chain,” promises Trumpf Product Manager Steffen Wagner. For the highest possible productivity, Trumpf equipped the new machine with a six-kilowatt fiber laser. This not only saves energy, but also cuts the parts particularly quickly. In addition, a lowerable die protects the workpieces from scratches during punching. The punching head of the TruMatic 5000 also has an electric drive patented by Trumpf, the DeltaDrive. This saves around 30 percent energy.

Fully automated material flow thanks to new SheetMaster

On the new TruMatic 5000, Trumpf has fully automated the material flow. This is possible thanks to the new SheetMaster – a technology that handles components in the manufacturing cell using grippers. With the new SheetMaster, the sensor-monitored suction cups on the grippers can be activated individually. As a result, the grippers grasp the workpieces even faster and more flexibly. This saves time, especially for small batch sizes. In addition, the SheetMaster can be connected to an automated Stopa warehouse. This independently supplies the manufacturing cell with raw material. The technology also palletizes and sorts the parts independently. Another advantage of the new SheetMaster is that it ejects the cut and punched components from the production cell. Companies can thus transport them directly for further processing, such as bending, deburring or grinding. This reduces non-productive time and increases production efficiency.

© Trumpf

Highest productivity with small batch sizes

As an additional automation technology, the TruMatic 5000 has a tool changer that automatically changes the punching and forming tools. This “ToolMaster” can hold 90 different tool cassettes. Users can produce small batch sizes and a high number of variants without having to manually retool the machine. In addition, the solution brings an automatic nozzle changer with inspection function. This prevents the machine from stopping overnight, for example due to a damaged nozzle.

The new punch-laser machine will be available from Blechexpo 2023. It is particularly suitable for companies that want to network their factory or have already done so and want to further increase their productivity with the help of automation. Typical fields of application are industrial kitchens, control cabinet construction or equipment manufacturing.

Trump

Trumpf offers manufacturing solutions in the areas of machine tools and laser technology. The company is driving forward the digital networking of the manufacturing industry through consulting, platform and software offerings. Trumpf is one of the technology and market leaders in machine tools for flexible sheet metal processing and in industrial lasers.

In 2022/2023, according to preliminary figures, the company generated sales of 5.4 billion euros with around 17,900 employees. With more than 90 companies, the Group is represented in almost all European countries, in North and South America, and in Asia. Production sites are located in Germany, France, Great Britain, Italy, Austria and Switzerland, in Poland, the Czech Republic, the USA, Mexico and China.

Web:

www.trumpf.com