When it comes to energy-efficient room air and process air technology, Rox Klimatechnik GmbH is a specialist. These large systems, which provide a good climate in the buildings, are often found on flat roofs, but also in internal functional spaces. The enclosure of the technology of such air systems is made by floor, wall and cover plates, as well as doors, condensate trays and weather protection roofs. To bend these sheets, Rox relies on a RAS XLTbend UpDown swivel bending machine.

© RAS

Corona has once again significantly increased awareness of clean indoor air. Rox Klimatechnik GmbH designs and manufactures complete ventilation systems according to the exact requirements of the customer. Exact means not only functional, but also dimensionally accurate. This allows the customer to freely configure the housing dimensions in length, width and height to the millimeter. Depending on the application, Rox manufactures the sheet metal components from galvanized steel sheet, coated material, stainless steel or aluminum. Thirty percent of the products are exported, and in addition to European neighbors, distant countries such as China, Indonesia, the USA and Canada also appear on the customer list.

In most cases, Rox designs, manufactures and delivers the fully tested equipment. For a fast-food company with a global presence, the specialists from Weitefeld are also partly responsible for commissioning the air-conditioning technology. In addition to restaurants and commercial kitchens, the ventilation systems provide clean air at the right temperature and humidity in office buildings, the pharmaceutical sector, mechanical engineering, hospitals and data centers.

“The devices and components are not mass-produced products, but are individually tailored to the customer’s needs in terms of dimensions and technology,” explains Managing Director Marco Fischbach. This performance promise requires a high degree of flexibility in manufacturing and assembly. When it comes to machinery, the Rhineland-Palatinate-based company has therefore relied on Swabian reliability for many years. RAS is therefore the long-term partner in bending. Since spring 2022, an XLTbend with UpDown swivel bending technology has extended the bending flexibility. This bending machine can bend sheet metal parts up to 3200 mm long with 3 mm steel sheet thickness.

© RAS

Swivel bending better and cheaper than die bending

The blanks made of 1.5 mm material can be very large in area, which immediately brings a swivel bending machine into play in the bending technology. Why swing bending has the preference over press brakes? The long leg of a sheet metal cassette remains on the stop system throughout the bending process. The stop fingers position the sheet on the bending line and the bending beam shapes the front protruding leg to the desired angle by its swiveling movement. With press brakes, the entire part would have to be lifted up and lowered again during bending, which quickly requires two or more people. The swivel bending process allows a single operator to produce even large-area sheet metal components on his own, although they can also be heavy and susceptible to buckling at these dimensions.

The operator works from the stop side of the machine and pulls the blanks from a stack of sheets onto the stop table. The stop fingers show him the insertion position. The ViN (Virtual Navigator) uses a laser beam to indicate the lateral positioning so that the sheets also hit the mold assembly exactly. Machine operator Steffen Künkler explains: “As soon as I start the bending process, suction cups emerge from the table level. They hold the sheet metal for automatic subsequent bending at the stop fingers.” Once one side of the bent part is finished, the suction cups pull the blank back so the operator can turn it on the table to the next side.

Bending up and down means that the parts do not have to be turned even if the bending direction is changed. Rox also has another RAS Flexibend bending machine that only bends upwards. This machine also does not allow automatic follow-on bends. “When we have sheets with opposite bends, we always take them to the XLTbend. Thanks to the UpDown technology and the automatic follow-on bends, we are at least 30 percent faster even with medium-sized parts. For large components, we would even add a second operator to turn the sheets,” explains Managing Director Marco Fischbach.

Due to the very individual equipment designs, the batch sizes of the orders are usually in the range of five to ten pieces. Only in exceptional cases do quantities of 30 to 50 parts per job occur. Production planning creates production lists in which the bending geometry and the required dimensions of the parts are listed. The machine operator calls up the required part program from the job list on the control. He adds the variables for length and width and the software calculates the new stop positions from this.

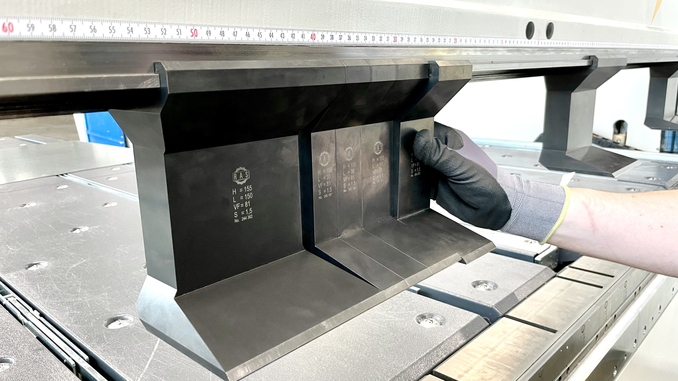

At the same time, it also determines the required mold setup and outputs it in the form of setup instructions. Steffen Künkler confirms, “It’s not uncommon for us to change over 30 times a day.” However, the setup is done quickly. RAS determined the geometry of the upper cheek tools during the project planning phase in such a way that the entire part spectrum of Rox can be bent with a single tool set. The tool segments are usually only moved and supplemented by adapter tools. This allows a tool change to be completed in less than a minute. The special tool has a front clearance of 81 millimeters. The same clearance area can also be found at the sides of the corner dies. This allows Rox to bend outer shells of sandwich elements with a low height and a deep inward projecting C leg.

© RAS

The Bendex software calculates the bending sequences, the position of the tool assembly, the insertion position of the blanks and much more from the CAD data of the bent part. This requires only a single mouse click and you can view the result in a 3D simulation even before bending. This flexibility allows Rox to manufacture all components to the millimeter in any dimensional combination. This is a decisive competitive advantage for individual plant configurations as well as for refurbishments or interior installations with limited space.

“In terms of component accuracy, the XLTbend has given us another huge push forward,” Marco Fischbach recounts. “The follow bends and the insertion aid provided by the ViN laser beam virtually eliminate mispositioning.” The calculation of the bending sequences is also quite a bit more precise than with the existing RAS flexibend swivel bending machine. This means that hole patterns match the holes in the system frames exactly, resulting in noticeably shorter assembly times for the long air-conditioning systems, which are made up of individual components.

Marco Fischbach (r.) Rox Managing Director, with machine operator Steffen Künkler

© RAS

If a service case ever occurs, which is very rare, RAS can connect directly to the machine via online support and rectify a fault. However, Rox is also fully convinced of the RAS service quality when spare parts are required. “We also still have an old coil line that RAS used to build. When we recently needed a spare part, it was on site within 24 hours. You won’t find customer service like this anywhere else,” Marco Fischbach enthuses.

Euroblech Hall 11, Booth B154

Web:

www.RAS-online.de