Attention: Danger of confusion! In 2020 – in the middle of the Corona pandemic – Michael Messner, Austrian entrepreneur and creative metal builder, ventured a new start by founding MTM-MetallTechnik Messner in Ragnitz near Graz. He is quickly rewarded for his courage and innovative ideas. An important part of the still young success story is its “Messer Experience”.

High-quality sheet metal technology and cut-to-size parts for steel, metal and mechanical engineering as well as custom products at marketable prices for regional customers – that was Michael Messner’s goal when he founded MTM-MetallTechnik Messner in Ragnitz, Austria, in 2020. The concept worked and Messner is writing a success story, even in today’s difficult economic times: In its third business year, the Styrian company can already report an increase in sales of almost 500 percent. “I am very pleased about the high demand for our products and the resulting excellent order situation,” Michael Messner, owner and managing director of the young company, proudly tells us. “We attribute a significant part of this success to our CNC flame cutting machine from Messer Cutting Systems and our positive experience with the cutting experts.”

Early on, before the company was founded, Messner set out to find suitable equipment. At the end of 2019, he launched his inquiries to various machine manufacturers. “It was important for me to be able to cover as many different customer requirements as possible with the machinery,” Messner explains his selection process. Likewise, delivery capability, service technicians in the vicinity, manufacture of the machine in the German-speaking region, customer support, accessibility of employees, professionalism, brand awareness and high quality were other decisive criteria for him. “In addition, the expenses to start the business should not exceed a certain limit,” Messner added.

© Messer Cutting Systems

High performance – low price

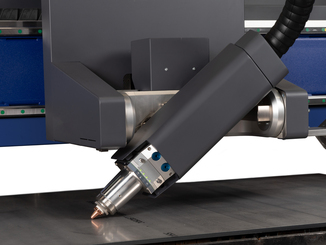

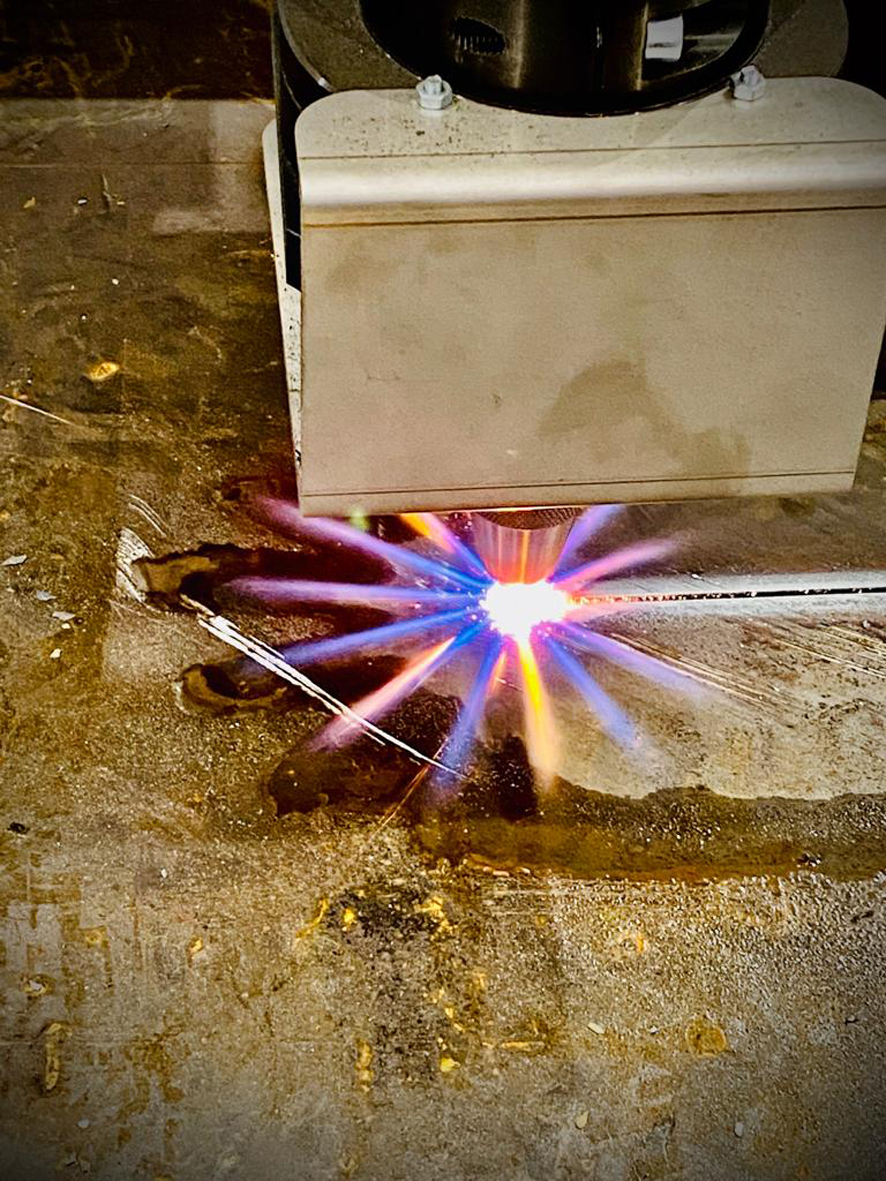

The race was won by the MetalMaster 2.0 from Messer Cutting Systems. The economical CNC flame cutting machine shows full power in a small space. Fast as well as easy to install and operate, the compact and space-saving system is an inexpensive entry-level machine for plasma or oxyfuel cutting – separately and also combined. In addition, high positioning speeds and intelligent height adjustment reduce non-productive times.

With the CNC Global Control 2.0 with touch screen, the machine operator needs only three clicks from loading the part program to cutting. The coordinated safety concept enables clearing during cutting operation. The bottom line is that the MetalMaster 2.0 is a powerful cutting machine for high productivity and flexibility.

“The MetalMaster is compact and very dynamic due to its lightweight construction. In plasma cutting, I think the system is one of the fastest machines on the market,” explains Messner. “Its speed, accuracy, quality and wide range of applications make it a machine that fits our needs perfectly.”

Complete package from a single source

In addition to the MetalMaster and the Global Control, the CAD-CAM software OmniWin and the use of Messer gases as well as service and training services by the experts from Messer Cutting Systems complete the overall package.

“It was important to us to provide MTM-MetallTechnik Messner with a machine concept that offers a great deal of flexibility and makes it easy for the newcomer to establish itself quickly and sustainably on the market,” says Gerhard Wimmer, head of the Messer Cutting Systems department at Messer Austria GmbH. The efficient and cost-effective machine covers approximately 98 percent of MTM-MetallTechnik Messner’s requirements in the 2D area with plasma, oxyfuel, beam processing and calculation with quotation generation via OmniWin.

© Messer Cutting Systems

Productive in five days

Despite the tight supply situation, Messer Cutting Systems kept the delivery date pretty much on time. Within only five days, the installation, training, testing, acceptance and commissioning took place in Ragnitz. Thus, the MetalMaster was already able to work productively on the fifth day at MTM-MetallTechnik Messner. “The commissioning on site with the experts from Messer Cutting Systems was very successful. I am very satisfied,” Messner is pleased with the successful project and his positive Messer experience.

Potential increased

Messner says the purchase of the machine has increased both his overall market and his sales potential. He was able to significantly expand the portfolio of services and components by supporting the machine. The result: higher satisfaction among existing customers and numerous new customers.

“The decisive factors here are accuracy and quality as well as our high speed and efficiency with a low error rate. From planning to the finished product, we are now significantly faster thanks to the OmniWin CAD-CAM software from Messer. It is user-friendly, has suitable interfaces for importing from planning programs, enables error-tolerant operation and runs flawlessly,” says Messner. “I would definitely choose the complete package again!”

Big plans

MTM-MetallTechnik Messner will continue to face multiple challenges in the future: With business customers, the company is under permanent pressure to keep up with the competition. In the private sector, individualized end-user items are increasingly in demand. In order to nevertheless remain on course for success, to keep quality high and prices low at the same time, the use of machines and software solutions such as those from Messer Cutting Systems is indispensable for Messner.

And then there is the problem of skilled workers: Due to the high demand, he is also looking for at least one more full-time employee, and additional employees are not excluded. “If growth continues, I am also considering investing in an additional laser machine from Messer Cutting Systems,” says Messner, explaining his plans for the future. In the future, he will continue to take into account quality and costs as well as service, advice and accessibility of suppliers.