The cutting experts from Messer Cutting Systems, together with their Messer Gase colleagues, will be presenting both their latest and proven solutions for process optimization in cutting technology in Essen. Efficiency, digitization, decarbonization, safety, health protection – a multifaceted program awaits trade fair visitors at the joint stand on around 530 m².

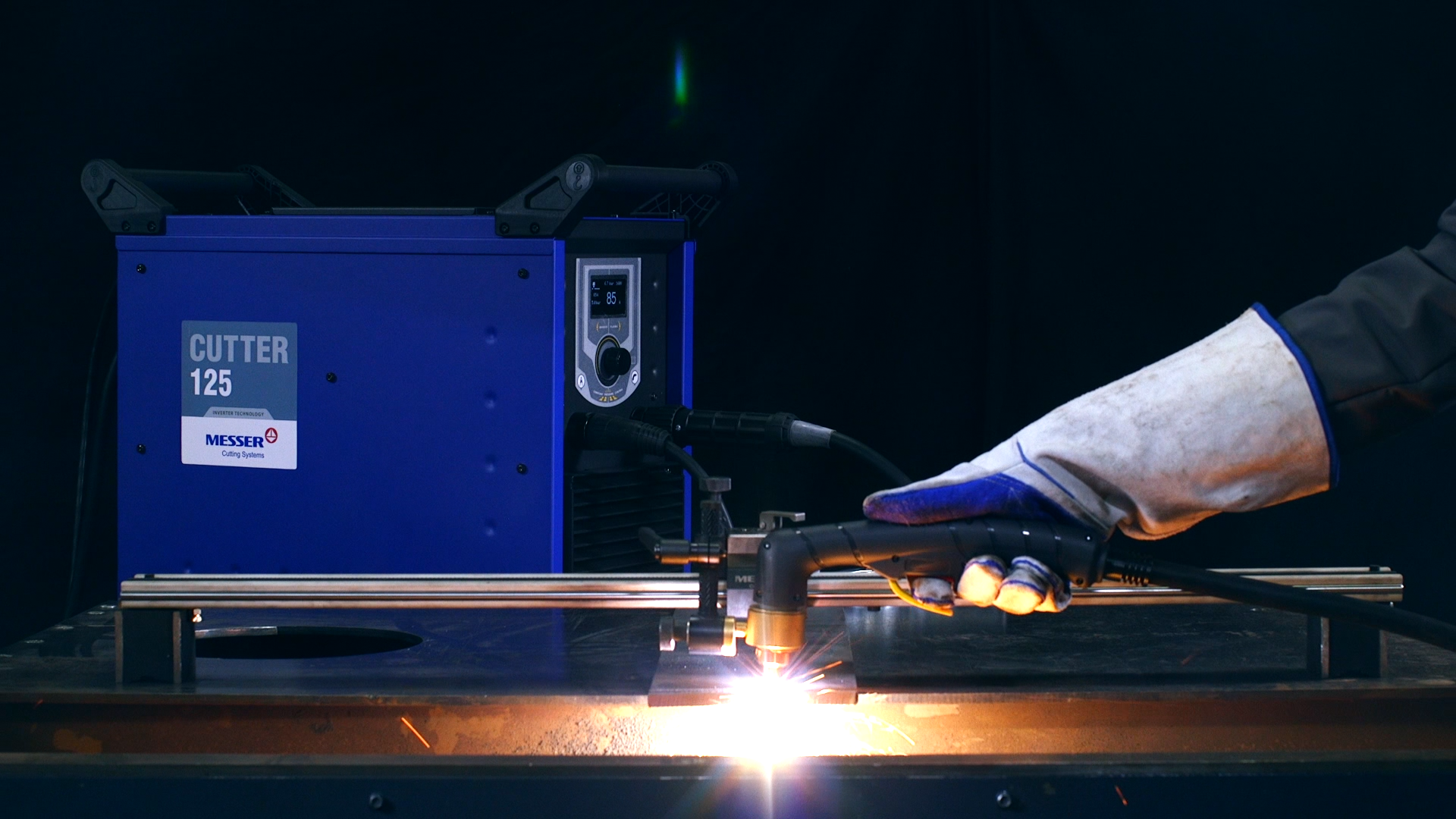

One of Messer Cutting Systems’ main attractions at Schweissen & Schneiden will be the live demo of the Element 400. Equipped with oxyfuel and plasma cutting technology as well as two additional marking tools, the flame cutting machine is suitable for a wide range of applications with high quality requirements. The Bevel-S plasma beveling unit promises maximum flexibility: Complex contours, holes or bevels for weld seam preparation can be cut effortlessly. In addition, the platform enables high-speed marking with proven and robust tools for quick and easy marking of various materials.

© Messer Cutting Systems

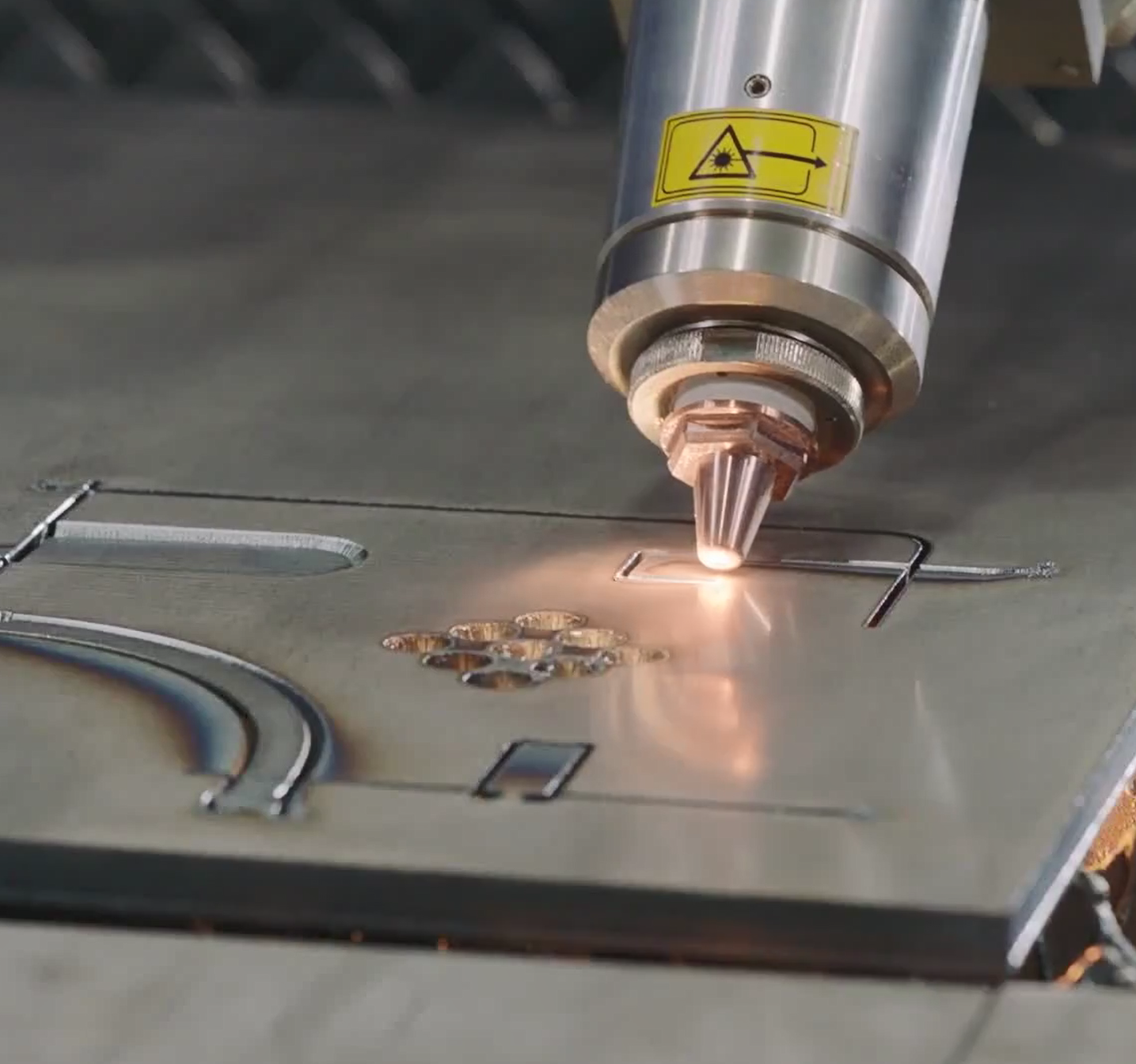

Optimal conditions for automation in laser cutting technology

Automation is the key to higher productivity and the answer to the challenges of our time, such as a shortage of skilled workers and scarcity of resources. Messer Cutting Systems creates excellent conditions for automated production with the latest developments in laser cutting technology and presents them at Schweissen & Schneiden.

It is often the little things that bring the decisive advantage, for example in handling: In order to be able to handle components better after processing, Messer cutting technology makes it possible, for example, to leave micro webs between the cut parts and the scrap frame. This means that each part does not have to be handled individually, but the sheets can simply be transported away as a whole using a loading and unloading system or shuttle table. This noticeably reduces non-productive time. The bars are so fine that they can be easily cut out of the frame later.

Those who want to see the Element 400 L laser cutting machine in action should also visit the Messer Cutting Systems booth. The experts will switch to the main plant in Groß-Umstadt for a live demonstration to show trade show visitors the remarkable dynamics and latest laser technology in the economical processing of XXL sheets.

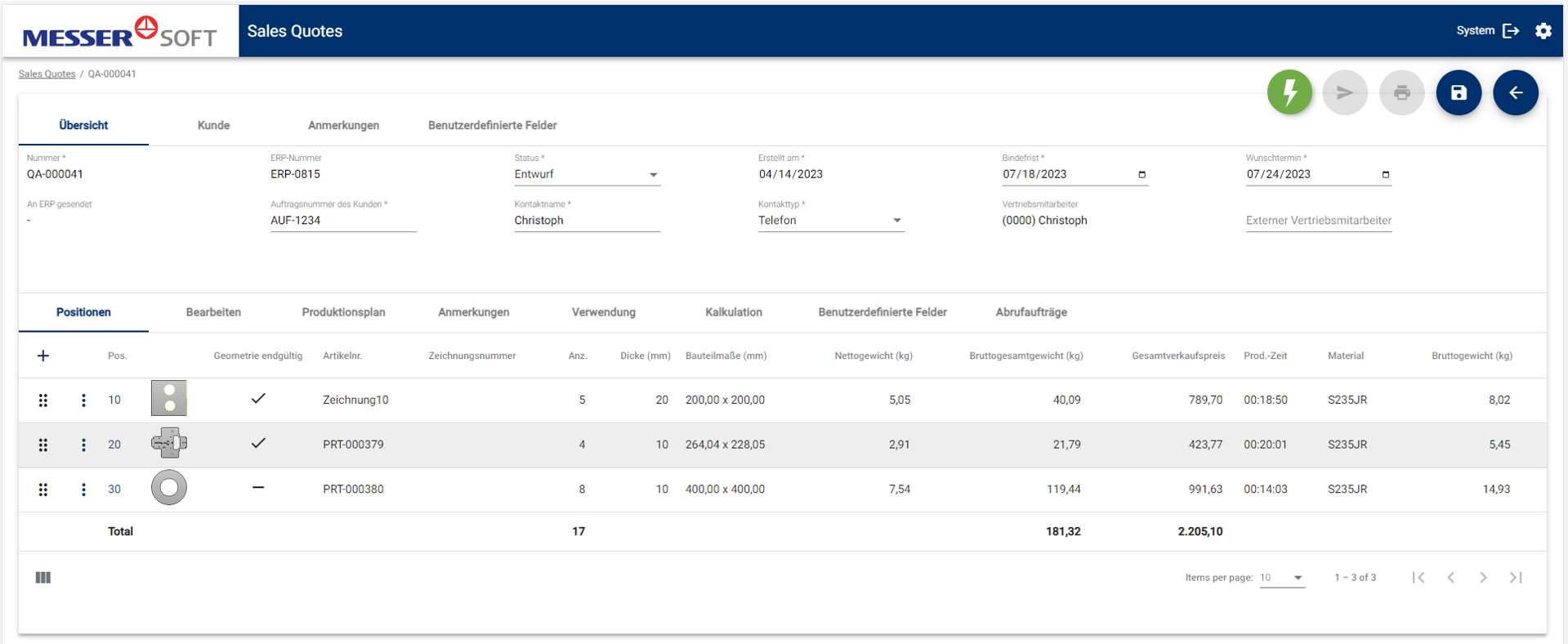

Get orders to production faster and more economically

© Messer Cutting Systems

Work preparation has a surprisingly large potential to noticeably increase efficiency in production simply and quickly. Messer Cutting Systems is making its trade fair debut at Schweissen & Schneiden, impressively demonstrating how this can be achieved superbly and with little effort.

With the new version of OmniFab, the software suite for digitizing production, cutting jobs can now be placed on the machine from customer quotations directly from the preliminary costing. Automated part nesting shortens or even skips the CAD/CAM nesting software step to do this. This increases the speed and significantly accelerates the process from quotation to the start of production of the order. For some use cases, this is a revolutionary and new approach. This is made possible by the direct connection of the software to the Global Connect machine control system. With the integration of the OmniWin CAD/CAM software, nesting plans can now be transferred to the machine in real time. Users save a considerable amount of time, especially due to the automatic preselection of all parameters required for production.

In addition to the focus on work preparation, trade show visitors will learn at a total of four stations how they can gain further competitive advantages with digitization solutions for production and easily enter Industry 4.0.

More safety in oxyfuel technology

In addition, visitors to Schweissen & Schneiden can experience the complete world of oxyfuel technology from Messer Cutting Systems up close and live with various combinable torch systems for welding, brazing, heating, flame straightening and cutting. With the innovative new development S.A.T. (Safety Advanced Technology), the cutting experts offer a special live demo highlight. The system proactively contributes to the safety of users and operations by automatically stopping the gas supply and extinguishing the burner in the event of a pressure drop.

Sustainable gas solutions

The welding and cutting experts will present innovative and proven gas solutions for process optimization at the joint booth. With new gas mixtures and technologies from Messer, users can increase efficiency, enhance safety and improve their environmental performance.

Sustainable production, occupational health and safety, and reduction of the CO2 footprint are increasingly in focus these days. At the same time, economical and productive solutions are as important as ever. This also has an impact on cutting technology and the choice of fuel gases. HyCut is here a new powerful and sustainable alternative to the conventional oxyfuel application technique.

There will be a very special highlight at the joint booth: Messer and Messer Cutting Systems will be presenting live at various stations the possibilities and advantages that HyCut offers.

Hall 8, Booth 8B13/23