In addition to the flexible Element 400 flame cutting machine and the new Element 400 L, specially designed for laser applications, Messer Cutting Systems will be presenting new solutions for digitizing production at Euroblech – from quotation preparation, nesting plans and production planning to material handling, production monitoring and process analysis.

Efficient cutting, digitalized workflows and optimized processes – at Euroblech, Messer Cutting Systems (MCS) will be showing future-proof ways to make the world of sheet metal working even more productive.

© MCS

Experience the most flexible cutting solutions live

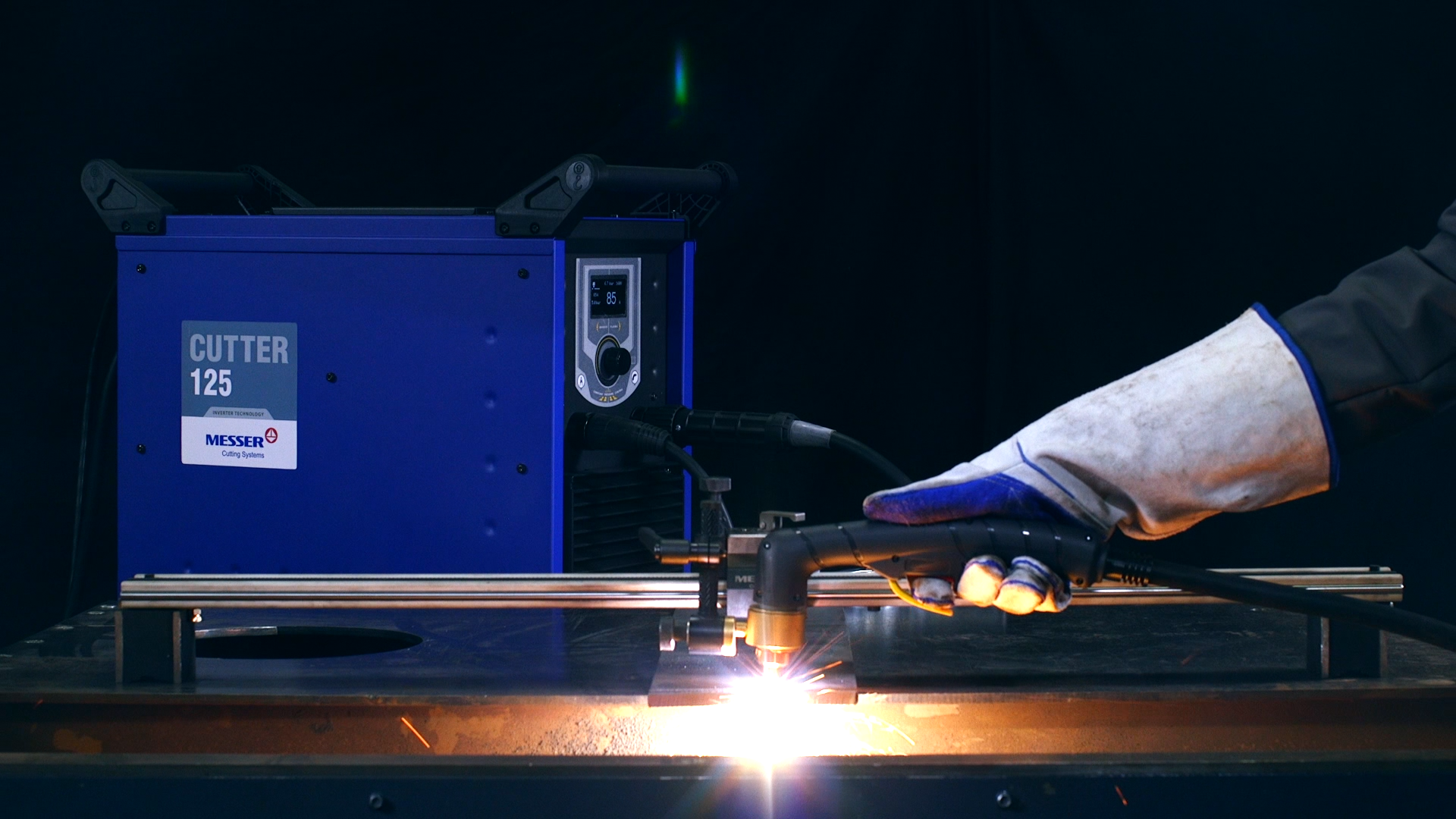

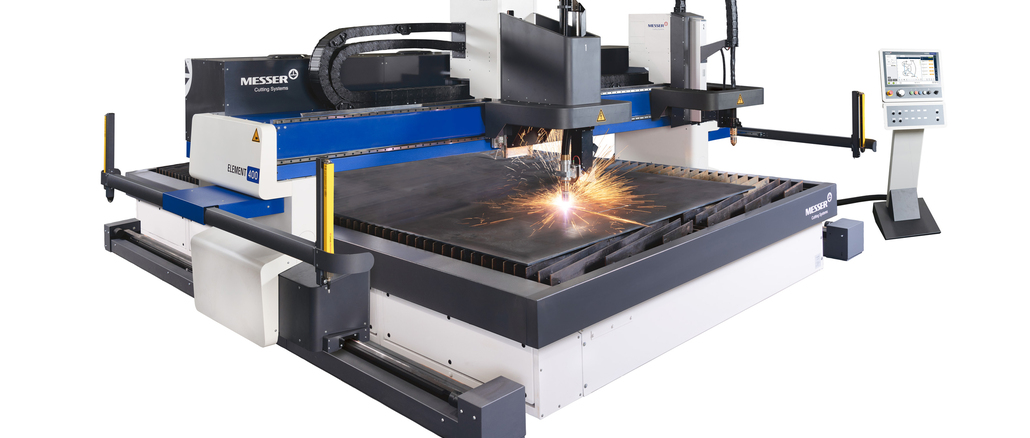

With the flexible machine platform Element, Messer Cutting Systems combines increased productivity, improved cutting quality and shorter cycle times with individual configuration. This allows users to adapt all cutting processes precisely to their specific requirements and face future challenges with confidence. At EuroBlech, Messer Cutting Systems will show the Element 400 with state-of-the-art plasma bevel technology and the new Element 400 L laser machine.

Equipped with oxyfuel and plasma cutting technology as well as two additional marking tools, the flame cutting machine Element 400 is suitable for various applications with high quality requirements.

Whether complex contours, holes or chamfers for weld seam preparation – the Bevel-S plasma chamfering unit, which was specially developed for use with the Element platform, ensures great flexibility. The rotation with high acceleration also enables high efficiency and thus increased productivity.

In addition, the Element platform offers numerous options for high-speed marking with proven and robust tools. In this way, components made of a wide variety of materials are marked quickly and easily.

State-of-the-art laser technology for maximum productivity and quality

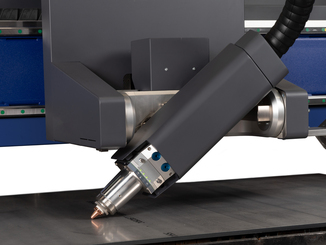

The Element 400 L laser machine scores with remarkable dynamics, the latest laser technology and the ability to economically process XXL sheets. Equipped with the innovative Bevel-U bevel cutting head, the advanced Laser Nozzle Control (LNC) and the easy-to-use Global Connect control system, it ensures maximum productivity as well as optimum user-friendliness.

With its unique design, the Bevel-U is perfect for producing precise and repeatable bevel parts – a major advantage in edge preparation for automated robotic welding.

© MCS

The road to digital production

Anyone who wants to master the current and future challenges, such as the shortage of skilled workers, the energy transition and the scarcity of resources, needs flexible processes. Software solutions from Messer Cutting Systems network machines and systems. In this way, companies from the sheet metal processing sector always act quickly and purposefully in production with the help of relevant information in real time. At EuroBlech, Messer Cutting Systems will present solutions for every phase of production digitization at six digital stations.

Connected to ERP systems, quotations are calculated automatically, quickly and reliably with the Messer software solutions on the basis of machining times, material consumption, dimensional drawings, production parameters and much more. Thanks to digital nesting plans and NC programs, even complex cutting jobs can be processed with high cutting quality quickly, efficiently, and in a material-saving manner. The digital cutting orders in production planning ensure optimum utilization of the machines. Cutting jobs are automatically sorted by urgency, material or other important attributes. This is how users get the best out of manufacturing.

The Global Connect control system provides intuitive operation for plate processing without manual intervention. Cutting jobs are executed automatically and the cut parts are checked for quality. Reliable production data reports support seamless traceability. Integrated material handling systems automate and control production and ensure minimal downtime.

With Messer Cutting Systems’ process analysis tools, production can be further optimized through real-time data from each connected machine with machine utilization, errors and reasons for downtime.

Future-proof Messer gas solutions

The welding and cutting experts will be presenting future-proof gas solutions for greater energy efficiency, optimized production costs, digitization and sustainability at the joint stand. These include the wide range of shielding gases for welding and cutting, precisely tailored gas mixtures for laser cutting applications, reliable data transmission of filling levels, higher purity through the use of particle filters and smart digital tools such as the “Messer Gas Scout”.

EuroBLECH Hall 13, Booth D138