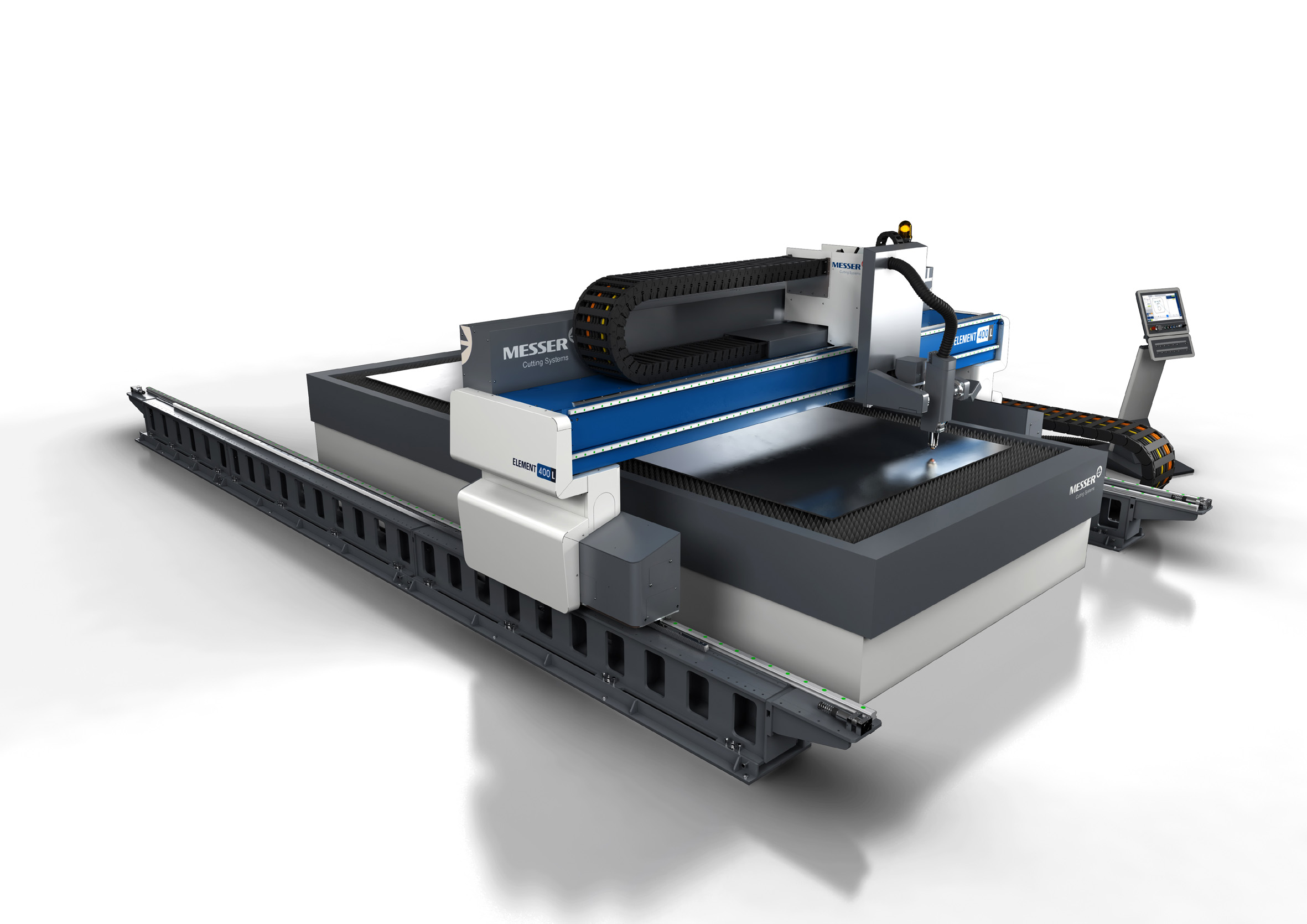

Rapidly increasing powers, different bevel shapes, new cutting gases require innovative solutions to make laser applications more effective and transparent. In view of the increasing shortage of skilled workers, automated processes are also indispensable. The new Element 400 L laser machine from Messer Cutting Systems (MCS) scores with high dynamics and the latest laser technology. The combination of various features and powerful software ensures maximum productivity and performance.

According to MCS, the Element machine platform gives metalworking companies unprecedented flexibility to configure their plant exactly to their individual requirements. “The Element 400 L laser machine is the newest member of our Element family. It provides a leap in performance in laser technology, combining uniform piercing and faster cuts in laser precision cutting. It cuts mild steel, stainless steel and aluminum with O2 and N2 and optional automatic gas mixing unit. The development also focused on automated nozzle management as well as material supply and removal and permanent data exchange and reconciliation throughout the entire workflow,” says Jörg Mosser, CEO Messer Cutting Systems Europe.

© Messer Cutting Systems

Powerful components for maximum productivity

With the Element 400 L, working widths between 1,600 mm and 5,100 mm and a working length of up to 25,000 mm are possible. It cuts mild steel, stainless steel and aluminum sheets up to a thickness of 40 mm. It is very fast with positioning speeds of up to 140 m/min and high acceleration (combination X/Y axis) and has high positioning accuracy thanks to the linear guides in the X and Y axes. The calculated construction of the portal also contributes to this.

High-speed lifters and modern process optimization techniques ensure significantly increased productivity. The high-quality components ensure reliable, laser-like precision with the highest dynamics. Independent, servo-driven tools offer versatile machining options. The CNC is designed to significantly improve efficiency, eliminate redundant information, and provide greater clarity in production operations. Setup time can be reduced by automatic positioning of several tools via the part program or the control (optional). “High-performance components are the basis of every Element machine. Thanks to the special features of Messer Cutting Systems, the Element 400 L can be adapted exactly to its requirements,” adds Ingo Staudinger, Product Manager Laser and Material Handling.

Plasma and laser combined

Six burner stations can be integrated into the Element 400 L – including automatic burner spacing and programmable burner selection. The user can also combine the latest laser technology (maximum two stations) with advanced plasma cutting technology.

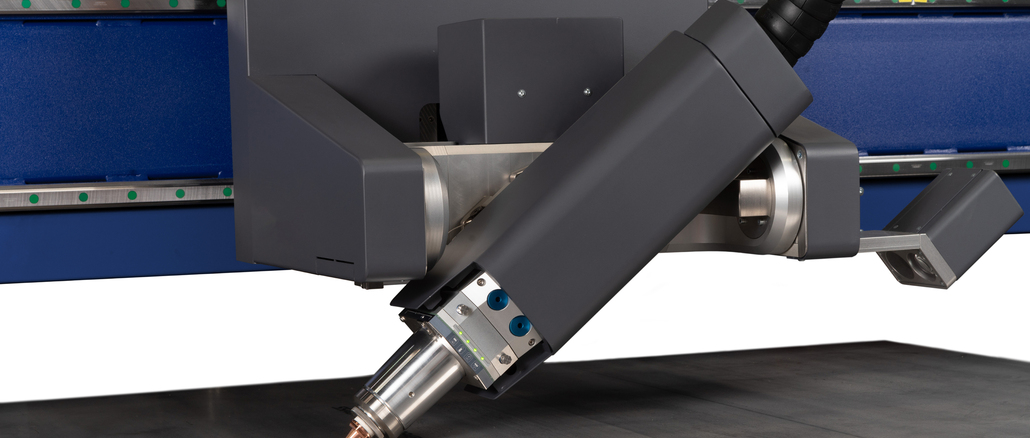

Ingo Staudinger: “The highlight of the Element 400 L is the Bevel-U bevel cutting head specially developed for the laser process. With its unique design, the Bevel-U is perfectly suited for the production of precise and repeatable bevel parts – a major advantage in edge preparation for automated robot welding.” Chamfers in the workpiece between -50° and +50° are possible, as well as different edge shapes for a subsequent welding process. The bevel angle is continuously adjusted during the laser cutting process. Magnetic collision protection for the cutting head is just as much a part of the Bevel-U’s design as a manual control panel for all drives, so that adjustments can be made directly on the machine.

Automatic test and calibration routine

“Today, automated processes are the basis for economical and precise production. One feature for the automation of the Element 400 L is the next-generation “Laser Nozzle Control” (LNC) nozzle changer. It quickly and reliably automates the setup work, ensuring maximum processing quality and productivity – for any material, any thickness and any process – and without manual intervention,” says Ingo Staudinger. The LNC ensures reliably high cut quality and reduced setup times. Machine downtimes are prevented and the sheet metal worker gains planning reliability and optimization.

High precision in the manufacturing process

For an accurate cut, the position of the sheet is crucial. There are always variations here. This is no problem with the Element 400 L. Before cutting, the sensor technology of the cutting nozzles determines the actual orientation of the sheet and the CNC program is rotated accordingly – manually from the control panel or fully automatically from the program. This considerably reduces the effort required to place the sheets and helps to make optimum use of plates.

Equally important for machining quality and accuracy in the manufacturing process is a smooth movement of the machine. The Element 400 L is equipped with a helical rack and pinion drive and precise linear guides. They form the basis for fluid motion sequences. Powerful AC servo motors provide fast acceleration of the cutting tool in and around holes as well as corners. This results in outstanding cutting quality.

© Messer Cutting Systems

Marking included

Various marking tools can also be integrated into the Element 400 L: In order to apply non-permanent markings such as layout lines or simple part identification to the sheets, Messer Cutting Systems offers an inkjet marker. A needle marker is available for the Element 400 L for permanent marking.

Safety first

“The high level of protection for man and machine is our top priority when designing a machine,” affirms Ingo Staudinger. “The functional safety technology of the integrated, internationally certified TwinSafe system not only prevents damage to the machine and minimizes downtime, but above all provides optimum protection for the operator.”

Digitization in production

The Element 400 L is rounded off by the powerful software solutions from Messer Cutting Systems. They ensure maximum transparency of operational processes, production planning and control. To further pave the way for continuous networking, the Global Connect can handle production orders directly and achieve maximum productivity, especially in combination with the products of the OmniFab family. The fact that the user interface remains clear and simply structured helps the user to access and operate all features without any problems.

Solutions beyond the machine

Messer Cutting Systems says it is “a global supplier of cutting-edge technology for the metalworking industry.” With more than 900 employees in over 50 countries worldwide, MCS is in constant dialog with customers to create sustainable user-oriented innovations.

The portfolio includes the topics Product, Digital, Services, Automation and Know-how. MCS wants to live up to the claim “Creating Solutions Beyond Machines” not only with state-of-the-art cutting systems and solutions for oxyfuel technology.

Appropriate services and training, our own software applications, and the integration of solutions from our technology partners, for example in the field of automation, complete the machines into future-oriented total solutions.

The technical know-how combined with customer-oriented thinking and acting has made MCS a possible partner for innovative total solutions around cutting systems worldwide for more than 120 years.