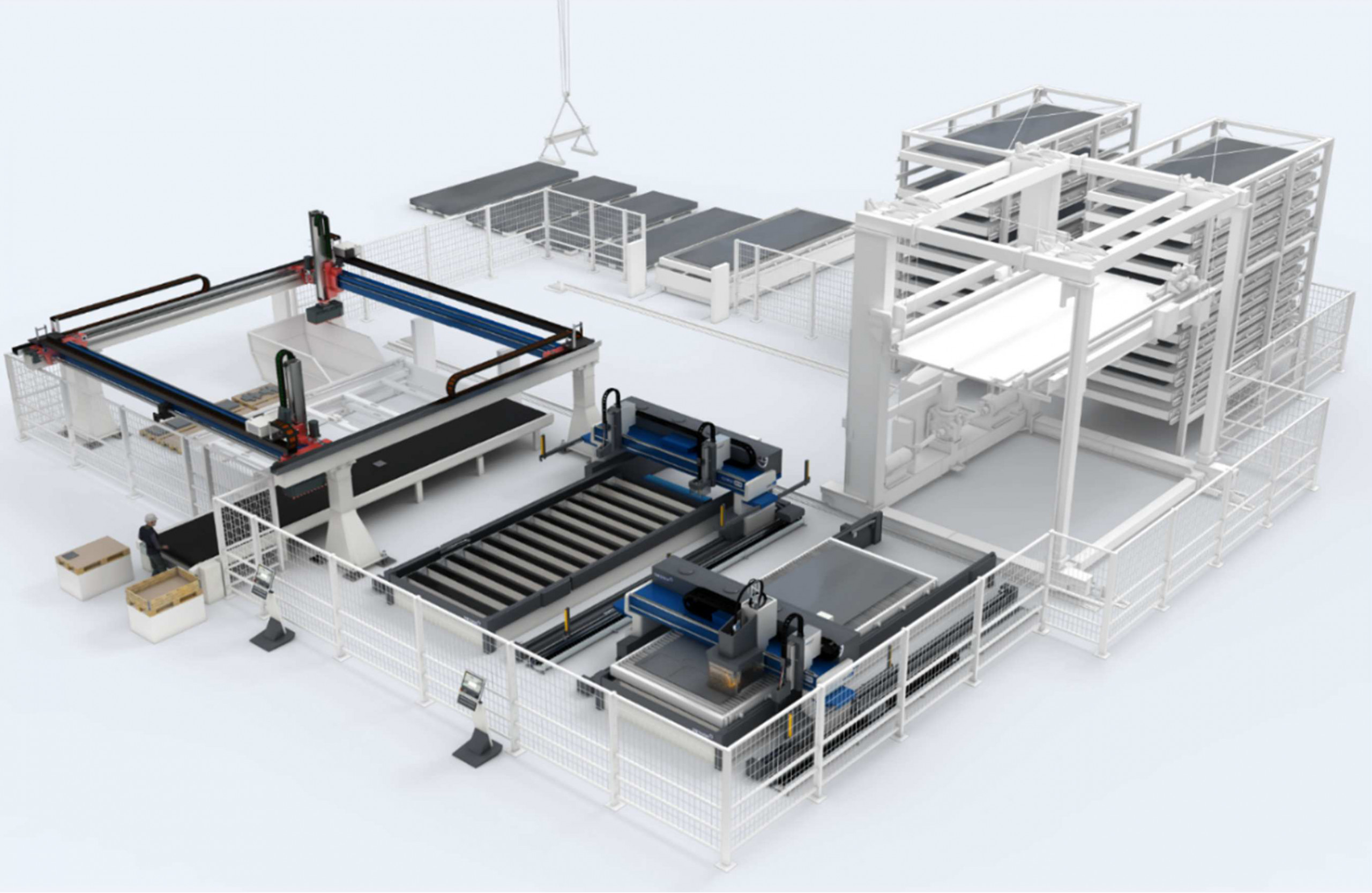

A shortage of skilled workers, energy transition and scarcity of resources – flexible processes are the key to mastering these current and future production challenges. Automation plays a particularly important role here. With the ICsort system, Messer Cutting Systems provides a pioneering material handling solution for sheet metal processing. In combination with the cutting systems from Messer Cutting Systems and the company’s own software, ICsort creates an even more efficient production environment.

Messer Cutting Systems is a global leader in the manufacture of cutting technologies. As a solution provider, the company not only supplies state-of-the-art cutting machines, but is also an expert in all cutting-related processes. In addition to the company’s own software, the cutting experts from Groß-Umstadt supply modular automation solutions for sheet metal processing that can be configured to customer requirements.

The latest development for sorting and handling processes is the ICsort system. In combination with the company’s cutting machines and software solutions, ICsort creates a highly automated production environment.

© Messer Cutting Systems

With the ICSORT system, all loading, unloading and sorting tasks can be automated efficiently. This enables the user to make maximum use of the machine. The provider cites the following advantages:

– maximum efficiency when integrating several cutting machines

– massive increase in productivity thanks to the fully automatic loading unit

– optimum material flow,

– reduced cutting machine downtimes (at almost zero)

– reliable material supply to several cutting machines

– considerable improvement in safety, as the automated unloading of the cutting table eliminates the need to step on it.

Thanks to its modular design, the system can be easily adapted to individual customer requirements. The system is suitable both for precisely positioning large raw materials on the cutting table and for sorting small cut parts quickly and efficiently. This is made possible by 40 individually controllable magnets. They can be flexibly adapted to all mild steel shapes and thus ensure the safe movement of the parts.

With two bridges and the powerful magnet units, ICsort can even handle large components – regardless of their dimensions or material thickness – without any problems.

The specially developed OmniFab software package also allows work processes to be optimally and purposefully controlled from the workplace.