“The Power of Productivity” – the motto of EuroBlech 2024 could not have been better tailored for Messer Cutting Systems: on two exhibition stands, the cutting experts from Groß-Umstadt will be showcasing a wide range of new developments and technical world premieres that are designed to increase productivity, sustainability and safety.

© Messer Cutting Systems

High-precision, productive and resource-saving sheet metal cutting, digitalized workflows and optimized processes through automation – at the world’s largest technology trade fair for sheet metal processing solutions, Euroblech 2024, Messer Cutting Systems will be presenting future-proof ways to make the world of sheet metal processing even more productive and safe.

Jörg Mosser, CEO Europe at Messer Cutting Systems: “Visitors to our exhibition stands can look forward to several highlights and lots of live action. In Hall 13, Stand B128, our new, high-performance laser cutting system will be celebrating its live premiere. I can’t reveal any more about it yet, the veil will be lifted during the trade fair. Our Bevel-U bevel unit will also be an important topic at our trade fair appearance.”

Thanks to its design advantages, the Bevel-U bevel cutting head enables the production of precise and repeatable bevel parts.

Even with material thicknesses of 50 mm, the system delivers a wide variety of bevel contours in the best cutting quality – a major advantage in edge preparation for automated robot welding. Combined with Laser Nozzle Control, productivity reaches a new level thanks to the fully automatic management of the cutting nozzles.

Efficient, resource-saving and safe oxyfuel applications with hydrogen

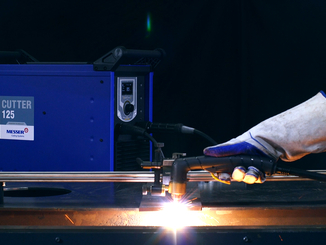

In addition to efficient cutting, heating and straightening, live applications with hydrogen also focus on health and safety at work as well as reducing the CO2 footprint: because hydrogen plays an important role as a fuel gas for oxyfuel technology on the way to decarbonizing the economy. Climate-friendly, safe and economical, this solution called HyCut is a powerful and sustainable alternative to conventional oxyfuel application technology. Messer Cutting Systems offers solutions for oxyfuel cutting machines and oxyfuel hand tools.

Together with Messer, the world’s largest privately owned industrial gas specialist, the possibilities and advantages of HyCut will be presented in a live demo at the trade fair stand.

© Messer Cutting Systems

Digitalization solutions for the sheet metal processing of the future

Under the motto “Smart, efficient, networked”, Messer Cutting Systems will be presenting digitalization solutions for the sheet metal processing of the future. A fully networked production environment with seamlessly integrated production control will be demonstrated – from component calculation and quotation preparation to automated and optimized production planning.

The new Advanced Planning and Scheduling System (APS) enables a precise overview of orders and efficient use of resources.

The enhanced calculation module OmniFab Sales Quotes offers precise quotation calculation. The CAD-CAM software OmniWin 2024 impresses with the revised 3D import of components, enhanced functions such as the copying of nesting plans and improved working ergonomics thanks to the dark mode.

Efficiency through automation

If you want to master current and future challenges, such as the shortage of skilled workers, the energy transition and the scarcity of resources, you need flexible processes. In addition to software solutions from Messer Cutting Systems that network machines and systems, the company’s automation solutions play an important role in effectively meeting modern production challenges.

For example, the modular material handling solutions from Messer Cutting Systems, which can be configured to customer requirements, enable the user to maximize machine utilization.

The advantages are obvious: high efficiency when integrating several cutting machines, massive increase in productivity thanks to the fully automatic loading unit, optimum material flow, reduced cutting machine downtimes (at almost 0 percent), reliable material supply to several cutting machines, considerable improvement in safety, as the automated unloading of the cutting table eliminates the need to step on it.

At the second stand in Hall 15-A05, Messer Cutting Systems will be presenting the ICsort, a solution for sorting processes. In combination with the cutting systems from Messer Cutting Systems and the company’s own software, the ICsort system creates an even more efficient production environment. The live demonstration of the ICsort will show the integrated software and hardware solutions in practice at the trade fair stand.

Web: www.messer-cutting.com

Euroblech Hall 13, Stand B128, and Hall 15, StandA05