Pilz now offers manufacturers a comprehensive safety solution in accordance with ISO 3691-4 for freely navigating mobile platforms – for an efficient flow of goods in production and logistics. It consists of the safe mini controller PNOZmulti 2 with new functionalities for synchronization monitoring and control of the PSENscan safety laser scanners. PSENscan, as the second component of the security solution, ensure productive area monitoring. In addition, the Industrial Firewall SecurityBridge provides protection against unauthorized access from the outside.

Freely navigating mobile platforms (Autonomous Mobile Robots, or AMR) can avoid obstacles or people without stopping. The required safety functions according to ISO 3691-4 are therefore complex. Especially when cornering, it must be possible to switch between several protection zones so that collisions between man and machine are ruled out and downtimes are avoided.

Dynamic zone switching

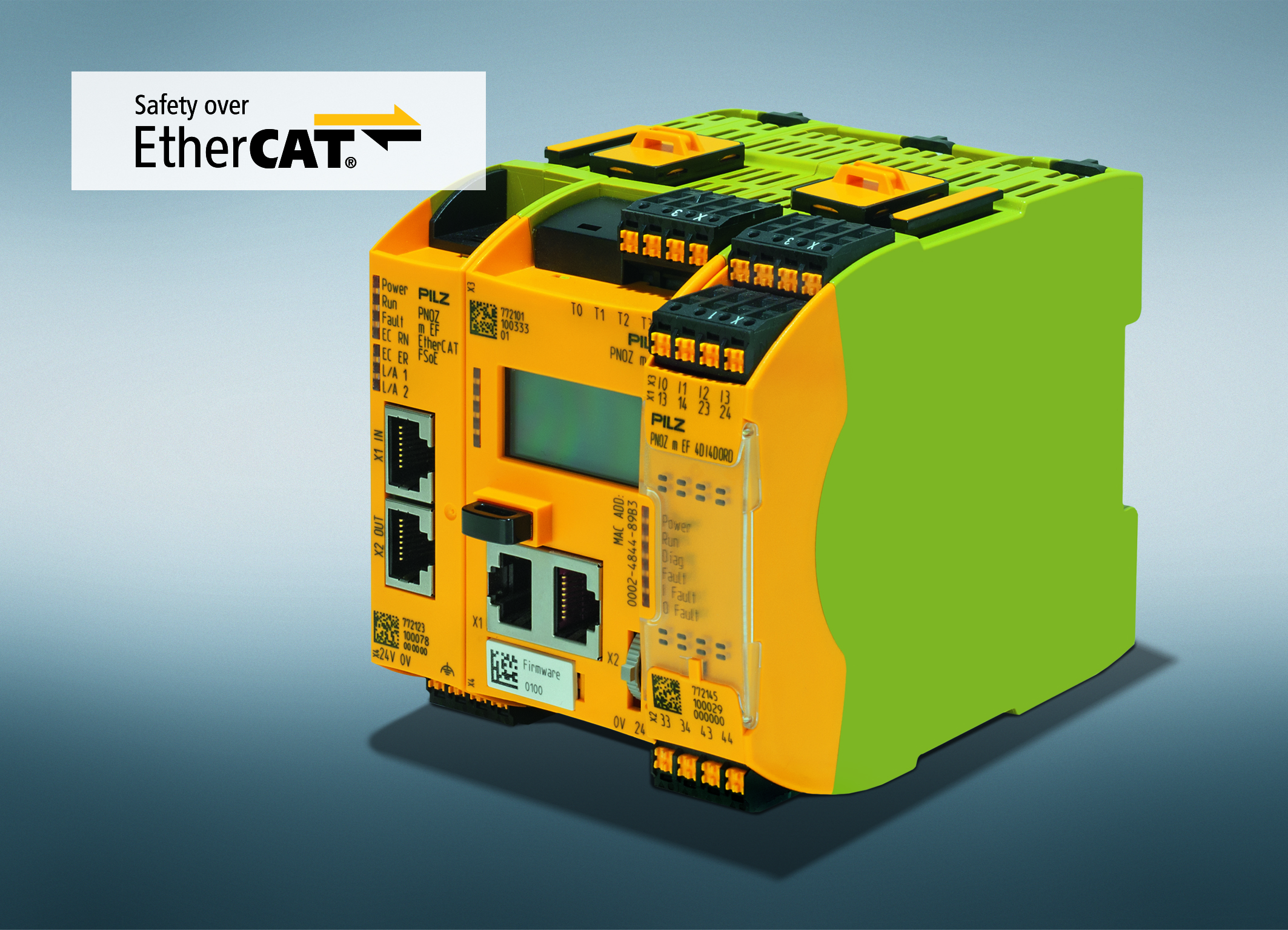

With the new function blocks for synchronism monitoring in the PNOZmulti Configurator software tool of the safe small controller PNOZmulti, the synchronous operation of the axes of an AMR can be reliably monitored. The program function compares the encoder values of the two axes to each other and thus enables conclusions to be drawn about the direction of movement of the mobile platform.

With this information, the safe zone switching required by the standard can be implemented dynamically in the PSENscan safety laser scanner, the second component of the Pilz safety solution. This is made possible by the PSENscan function block in the PNOZmulti Configurator, which is also new: the “zone selection function” can be used to dynamically switch the up to 70 protective fields of PSENscan. At high speeds, the protection zones are larger in order to detect obstacles at an early stage. At slow speeds, these can be correspondingly shorter in order to generate as little downtime as possible. This is how the AMR moves safely and efficiently.

Easy localization and navigation

The configurations created in the PSENscan Configurator can be imported and processed in the navigation computer of the freely navigating platform. The PSENscan safety laser scanner provides the distance data of the laser beams for localization and navigation of the mobile application. Data transmission is via UDP (User Datagram Protocol) and can be accessed via commercially available, open interfaces using a C++ library or ROS (Robot Operating System). This provides users with flexibility and allows for easy creation of environment maps for navigation.

Protection against unauthorized access

As freely navigating platforms, AMRs communicate with their master controller by radio. This makes them vulnerable to unauthorized data access or manipulation from the outside. Card data could be queried, AMRs and thus ongoing production could even be shut down in the worst case. The Industrial Firewall SecurityBridge protects the network against manipulation and ensures that no one can access the internal IT network of the mobile platform without authorization during operation. It completes the safety and industrial security solution package for autonomous mobile robots from Pilz.

Services make offer complete

The solution for safeguarding complex AMRs expands Pilz’s existing range for safeguarding track-bound automated guided vehicles (AGVs). Pilz has also been supporting AGV operators for years with a comprehensive service package for implementing safe AGV applications. Pilz’s offering starts with the development of safety concepts in the design phase through to commissioning or, on request, international conformity assessment, including training. This meets both the requirements of the relevant ISO 3691-4 and ensures productivity in operation.

BlechExpo:

SPS 2023 Hall 9, Booth 370