Under the motto “Smart, efficient, networked”, Messer Cutting Systems presented innovative digitalization solutions for the sheet metal processing of the future. The cutting experts from Groß-Umstadt demonstrated a fully networked production environment with seamlessly integrated production control – from component calculation and quotation preparation to automated and optimized production planning.

As a solution provider, Messer Cutting Systems, manufacturer of cutting technologies, not only supplies state-of-the-art cutting machines, but is also an expert in all cutting-related processes. The coordinated solutions for metalworking companies use digitalization to optimize processes, improve efficiency, increase productivity and reduce costs.

Precise overview and efficient use of resources

Focus on the newly integrated Advanced Planning and Scheduling System (APS). APS provides a precise overview of orders and ensures efficient use of resources. This solution drives the economic success of modern production operations and ensures that companies make optimum use of their resources.

© Messer Cutting Systems

Precise calculation

The enhanced OmniFab Sales Quotes calculation module deserves special attention. The module enables accurate quotation calculation and helps companies to precisely analyze their material and production costs and remain competitive. Connected to the ERP system, quotations are calculated automatically, quickly and reliably. The basis for this is formed by processing times, material consumption, dimensional drawings, production parameters and many other key data. This saves time and minimizes errors. At a time when efficiency in production is becoming increasingly important, such precise calculation of materials, components and work processes is essential in order to remain competitive.

Extended functions and improved ergonomics

Another highlight at the trade fair was the CAD/CAM software OmniWin 2024. OmniWin is an easy-to-learn, clear design and nesting software that adapts intelligently to the machines and individual requirements. It performs all cutting tasks tailored to order-related production with CNC flame-cutting machines.

The latest version offers numerous innovations: It impresses with the revised 3D import of components, extended functions such as the copying of nesting plans and improved working ergonomics thanks to the dark mode.

Messer Cutting Systems also presented its solutions for sorting processes at EuroBlech with the ICSort. In combination with Messer’s cutting systems and the company’s own software, the system creates an even more efficient production environment.

Background

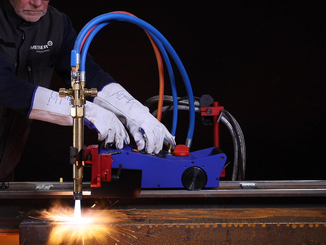

Messer Cutting Systems is a global supplier of high technology for the metalworking industry. With more than 900 employees in over 50 countries worldwide, MCS is in constant dialog with customers to create sustainable user-oriented innovations. The portfolio includes the topics Product, Digital, Services, Automation and Know-how. The company lives up to its claim of “creating solutions beyond machines” not only with state-of-the-art cutting systems and solutions for oxyfuel technology.

Appropriate services and training, in-house software applications and the integration of solutions from technology partners, for example in the field of automation, complete the machines to create future-oriented complete solutions.

The know-how combined with customer-oriented thinking and action has made MCS a worldwide partner for innovative complete solutions for cutting systems for over 125 years.