Continuous innovation is the order of the day at the Chemet Group – Europe’s largest manufacturer of pressure vessels, cylinders, tankers and tank wagons for various types of liquefied gases. A large and ambitious project to build tank wagons has now led to the renewal and expansion of the machinery at the site in Poland. In addition to a modern production hall, this also includes a PowerBlade cutting machine from Messer Cutting Systems. The results are really impressive: Chemet not only cuts 95 percent of all workpieces with the PowerBlade laser machine without additional chamfering. The cutting times for the same assemblies have been significantly reduced compared to the plasma cutting process. The employees are satisfied. The range of structural and stainless steels with different surface qualities has been expanded.

Chemet Spółka Akcyjna

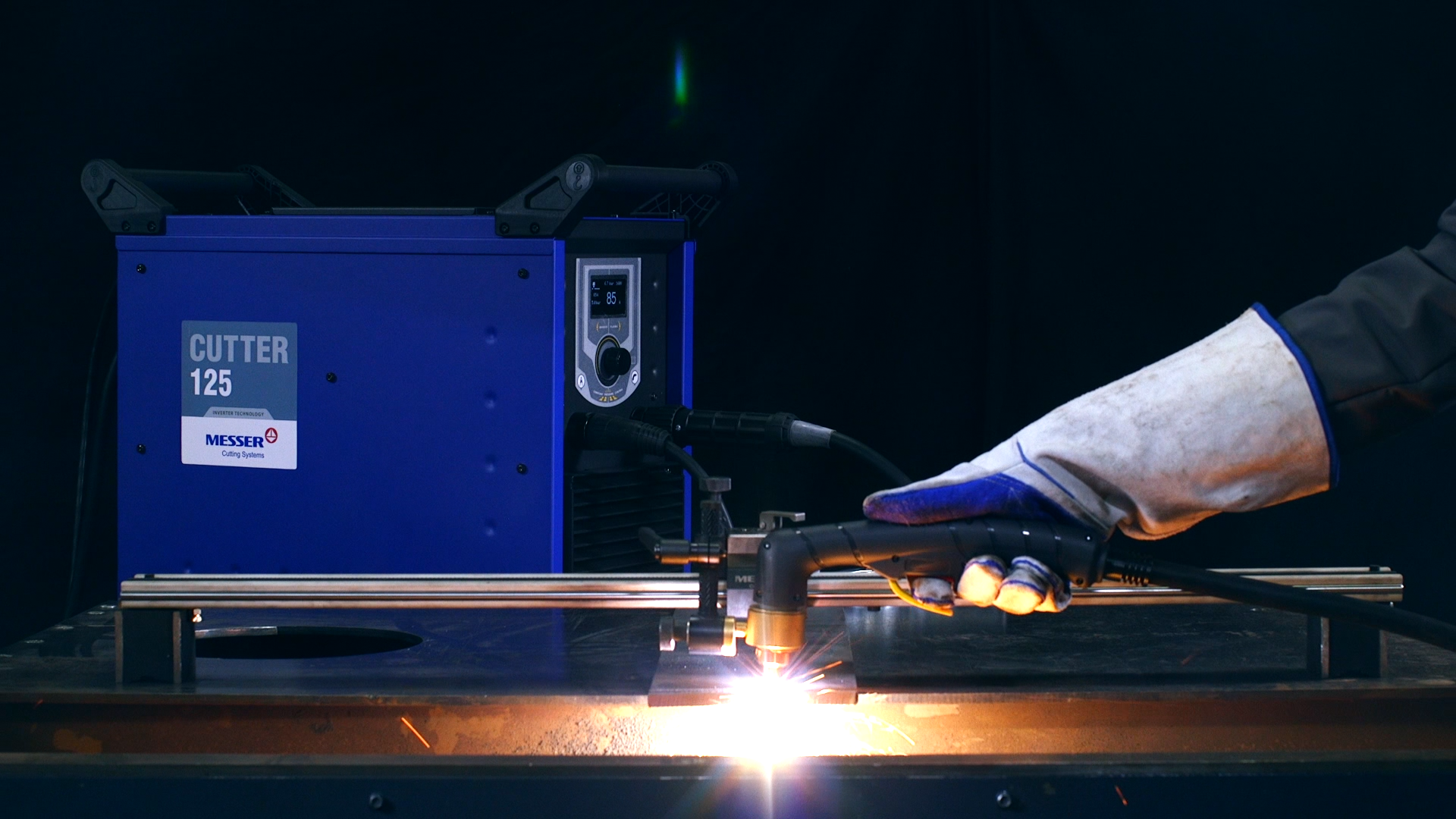

The experts from Messer Cutting Systems and Chemet have known each other for some time: Chemet invested in a MultiTherm, an oxyfuel cutting machine with three Alfa torches from the cutting experts in Groß-Umstadt, back in 2007. “Satisfied with the machine, but quickly looking for more performance, Chemet received an OmniMat with Plasma HPR 260 XD including PKS bevel unit for vertical and bevel cuts and the OmniScript needle marking system in 2011,” recalls Artur Szygula, technical consultant at Messer Cutting Systems Polska and responsible for the customer.

There is also a good relationship with Messer Gase Polska. Chemet obtains the required technical gases from there and in return manufactures large gas tanks and pressure vessels for knives. Ten years after purchasing the OmniMat, Chemet’s increasing performance requirements led to the investment in the PowerBlade fiber laser cutting system for large-area processing.

Despite Messer Cutting Systems Polska’s good experience and personal support at Chemet, the machine supplier was not automatically selected to deliver the new machine. The current tank wagon project is receiving significant funding from the European Union (EU), which obliged Chemet to carry out an in-depth technical analysis of the production process requirements and extensive market research into the solutions available on the market in 2021.

The demands on the new laser machine and its manufacturer were correspondingly high. The new cutting machine should not only be state of the art. The list of requirements also included numerous equipment features such as:

– Fiber laser with at least 6,000 watts of power

– Dynamic, automatic adjustment of the laser power depending on the cutting speed (for fine contours and small details)

– Infinite continuous rotation of the rotating bevel head type “I”; “V”; “Y”; “X”; “K”

– Stepless adjustment of the bevel angle of ±50°

– Adaptive optics, for example changing the focal length during piercing

– Maximum lifting of the head of 300 mm

– Magnetic head holder with collision protection

– Integration capability in the existing nesting software

Chemet Spółka Akcyjna

Tests passed

The final decision was preceded by extensive tests. The Chemet team wanted to see for themselves that the chamfering unit of the PowerBlade actually achieves an angle of 50°, so a team set off for Messer Cutting Systems in Groß-Umstadt.

In detail, burr-free cuts should be possible on sheets up to 3 x 10 m in size and up to 20 mm thick with chamfers of up to 15 mm. A maximum angle of ±50° and a tolerance of less than 0.5 mm on the V, Y, X and K seams should apply to 90 percent of the bevel parts.

Together with laser specialists Oliver Trunk and Marek Lipiński, the high requirements were implemented with sample cuts. Very successful, as Chemet’s decision shows:

“We opted for the PowerBlade from Messer Cutting Systems because the quality of the parts it produces is very high. Our choice was underpinned by our good experience with the Messer machines in our company,” says Dawid Krawczyk, technologist at Chemet and responsible for the implementation of Messer Cutting Systems solutions.

The laser cutting system was installed in the newly built production hall in March 2022. The chamfering unit works with a 6 kW IPG laser and, like the OmniMat, also uses the OmniScript marking system. The OmniBevel software solution is used for bevel cutting and as a post-processor for third-party software. The OmniFab Machine Insight module is designed to provide important information about the cutting process in real time during operation.

Processes optimized

Chemet has succeeded in integrating several production steps with the PowerBlade and thus optimizing processes. Whereas previously there were the steps of “cutting”, “processing” and “sanding”, quality is now achieved in a single work step. The machine cuts around the clock, six to seven days a week. “We now cut a wide variety of structural and stainless steels automatically, even with different surface qualities, without the need for manual intervention,” explains Dawid Krawczyk.

The shuttle table system in particular has led to further savings and optimizations. The sheet metal is now changed and the finished cut parts are unloaded while the machine is running. This leads to enormous savings in working time.

Vibration trays are fitted under the changing system. Slag, cutting waste and small parts are transported out of the machine enclosure and the unloading area. There, everything falls into easily accessible collection containers. Fishing for small parts in the cutting table is therefore a thing of the past. Time-consuming production breaks to empty and clean slag pans are also no longer necessary.

Satisfied employees

“The safety of our employees at work is very important to us. To this end, the PowerBlade has first-class safety functions. All openings of the laser safety housing are safely monitored. The laser is locked during the cutting pallet change. Once the change has been completed, safety is restored by closing the loading gate. The machine automatically starts the next job,” explains Pawel Pachniak, Maintenance Manager at Chemet. “Our operators and technicians are delighted with the improved working conditions in terms of pollutant and noise levels and enjoy working with the new machine and its innovative control system,” adds Miroslaw Soremba, Product Manager.

Faster, better, more independent

“The new laser machine has brought us a number of improvements,” says Maciej Petrolewicz, Production Department Manager. “We have significantly shortened the cutting times compared to the plasma cutting process for the same assemblies and save time-consuming processing for bevel cuts. The additional chamfering process is now no longer necessary for 95 percent of the cut workpieces. We now also cut bevels in high-alloy steels (CrNi). This has significantly expanded our range of services and makes us independent of the supply of parts by subcontractors.”

Chemet makes the Messer Experience

“The purchase of the Messer laser machine is part of a larger project at Chemet. The laser has enabled us to implement our high-quality and detailed requirements. In addition to meeting the technical requirements, we were impressed by the high-quality technical advice, the very good test results for the sample cuts and the experienced team on site with efficient service,” explains Chemet’s Technical Director, Katarzyna Głowik-Popiół. “We would choose Messer again at any time. After thorough market analysis and our experience, Messer is the leader in the manufacture of lasers with bevel function.”

Despite the current major tasks, Głowik-Popiół is already thinking about the future: “We hope to be able to offer cutting services in our region in the near future. To this end, we will probably invest in a second laser cutting machine from Messer Cutting Systems.”