In order to continue to meet the highest quality requirements according to international standards in mechanical and plant engineering and to produce economically, the Austrian company Thöni Industriebetriebe GmbH wanted to replace an ageing flame-cutting machine at its Landeck metalworking plant. Together with Messer Cutting Systems, an efficient solution was implemented that led to better cutting quality, cost savings and easier work processing.

Thöni Industriebetriebe GmbH

Thomas Lang, Head of Purchasing and Work Preparation at Metallwerk Landeck, describes the starting point for the project: “Our aim is to develop, design and manufacture products and services of top international quality at competitive prices, taking environmental and energy aspects into account. We set ourselves the goal of continuously improving our services. In doing so, it is important to us to give preference to new and more efficient technologies.” A twenty-year-old flame-cutting system no longer met these requirements, particularly in terms of cutting quality and efficiency. Thomas Juen, foreman at the Landeck metal plant, adds: “The manual steps and inefficient use of the old system had a significant impact on our production processes.”

Challenging goals

Martin Haag, work planner at Metallwerk Landeck, took over the management of the project. He clearly defined his goals with Thomas Lang right from the start. Metallwerk Landeck needed a modern machine that delivers outstanding cutting quality, minimizes reworking steps such as weld seam preparation, automates the cutting of tubular parts and cuts sheet formats up to 8.5 x 2.5 metres.

Thöni Industriebetriebe GmbH

Use experience

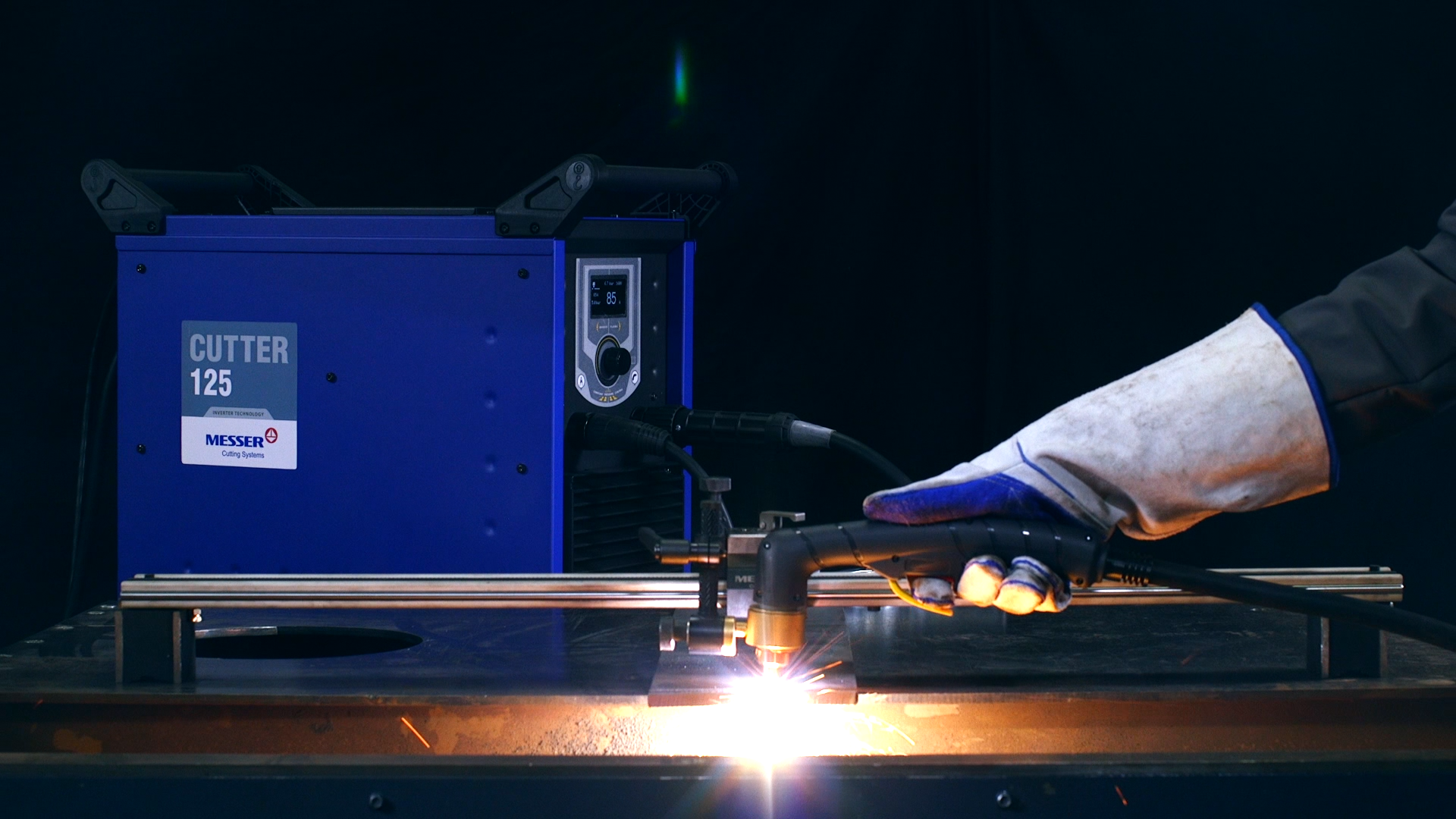

“The contact came about through a tender for CAD-CAM software that had been issued by Thöni two years previously,” recalls Gerhard Wimmer, Head of Messer Cutting Systems Austria. “Thomas Lang and Martin Haag managed the tender at the time and held discussions with manufacturers. We then organized several visits to reference customers for Thöni. There were visits and an exchange of experiences with three Messer Cutting Systems customers. This enabled us to convince Thöni of our merits.” In addition to the visits and discussions, other criteria were also taken into account in the decision, says Martin Haag. In addition to the quality of the machine, factors such as the fast and short-term availability of spare parts, competent local contacts and efficient support were decisive. There were also specific requirements for the flame cutting machine. It should have specifications such as plasma cutting up to 35 mm, drilling at a ratio of 1:1, bevel cuts up to 50° and a pipe rotation axis for pipes up to 500 mm in diameter. The overall solution from Messer Cutting Systems around the MultiTherm flame cutting machine was ultimately convincing. The cutting system combines plasma and oxyfuel cutting. Thanks to its diverse equipment options, it is designed for a wide range of applications. The CNC cutting machine is efficient with the highest demands on quality and productivity. The MultiTherm for Thöni is equipped with a Skew Rotator Delta plasma beveling unit, an Alfa oxyfuel torch and the PTC500 pipe cutting system. The Skew Rotator Delta offers the possibility of cutting bevels with up to 400 A plasma current. This increases the range of options for cutting for users of medium to large portal machines. The Alfa burner is characterized by integrated height sensing and automatic ignition. The burner nozzle can be changed without tools, which drastically reduces set-up times. The burner effectively cuts right to the edge of the plate, ensuring better material utilization. With the modern and flexible OmniWin design and nesting software, Thöni has a suitable tool for work preparation in flame cutting, for oxyfuel, plasma and laser cutting. The Austrian experts relied on the OmniBevel knife software for bevel cutting. It ensures straight cuts, cylindrical holes, exact chamfer angles and absolutely dimensionally accurate components. Thöni also relies on gas solutions from Messer Austria.

Thöni Industriebetriebe GmbH

Special solutions required

Martin Haag still remembers the special requirements for the system layout: “The old gas supply was converted by Messer Austria and expanded to meet our new needs. To do this, we created a detailed system layout in the area of the old system in order to be able to place the extraction system in the foundation. The new system was installed over the turn of the year so as not to disrupt production as much as possible.” “The milestone for us was definitely the commissioning of the new system and the immediate start of production. This meant that we had no downtime in production,” says workshop manager Thomas Juen, pleased with the successful installation of the system. Another positive aspect is the excellent cooperation between Messer and Thöni, explains Juen. Messer is also always available during operation and is always on hand with help and advice.

Save time and costs

Lang, Haag and Juen all agree that many things have improved since the new plant went into operation. These include high cutting quality, modern bevel cutting, precise tube cutting, an increase in the sheet formats that can be cut and simpler sheet layer compensation using a laser diode.

© Thöni Industriebetriebe GmbH

“We now produce small hole diameters and chamfers directly on the machine. This means they no longer have to be laboriously milled or drilled. This has significantly reduced costs. Today, we also cut thicker sheets than before. What’s more, we now have much shorter set-up and changeover times. All of this also saves us time and money,” sums up Haag. “With the tube turning axis, we can now process tubes with a tube diameter of 50 to 500 mm and a tube wall thickness of 2 to 30 mm and 6 m in length. Another new feature is that we can apply chamfers to the components,” continues Haag. The production team is also pleased with the improved working conditions. Placing and setting up the metal sheets has become much easier. By moving the extraction system into the foundation, the machine is more accessible and requires less space. The machine control system is more modern, making the machine easier to operate.

Digitization and automation

“We are very satisfied with our ‘Messer Experience’ and would opt for this solution again,” says Lang in retrospect. “Messer has delivered a practical overall package, even compared to the competition. The quality feature ‘Made in Germany’ was implemented perfectly.” Haag attributes the success of the project to a few specific things that he would also recommend to any company that needs to replace old systems: “In terms of a long-term solution, you shouldn’t save money in the wrong place. We felt well understood by Messer Austria right from the start and had the opportunity to visit various reference plants to talk to the operators about their experiences.” Areas of responsibility were also clearly defined. The selection process is certainly very complex and varies from case to case. The more you invest in preparation and planning, the easier and clearer the process will be. The next priority for Thöni in Landeck is the digitalization and automation of work processes. Because this is where success for the future lies. “We are planning to completely digitalize the cutting area. This will later include the ERP connection. We can well imagine using the Industry 4.0 software suite OmniFab from Messer Cutting Systems here. With the new system, we have definitely taken a first step in this direction,” concludes Lang.