As usual, RAS will present an impressive range of machines on an impressive stand. Here is a small selection.

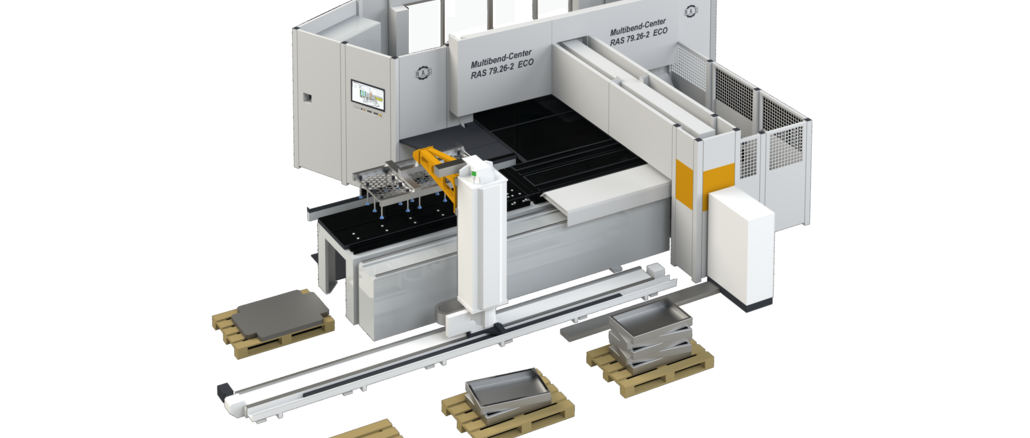

Multibend Center Eco with automation

After the RAS Multibend-Center Eco had found its fan base as an inexpensive entry-level solution for automatic bending, the desire for simple automation in loading blanks and stacking the finished bent parts quickly arose. Here the solution is Multibend-Center Ecoauto with 2560 mm bending length. The compact design requires only a hall area of 8950 x 10900 mm.

As an alternative to manual loading of the blanks, the Palletizer robot arm takes over loading of the blanks in the ECOauto variant. For this purpose, the suction frame of the palletizer moves over the stack of blanks stacked with edge precision. With its pre-suckers, the suction frame separates the top blank from the stack of sheets. With its lifting axis, the suction frame brings the blank to the height of the suction measuring table, moves to the transfer position and places the blank on the suction measuring table.

Suction cups emerge from the table surface, which is equipped with brush plates, and hold the sheet during the reference process. The measured values are used to position a slanted blank up to the bending line. Due to the design structure of the main manipulator, the measurement of the subsequent blank can already take place up to a certain size while the bending cell is still working on the current bent part. Anticipated alignment shortens cycle times and speeds up operations. Once the Magic Eye board scanner has measured the board, the feeder feeds it to the main manipulator.

After the main manipulator takes over the blank, it positions it on the bending line with hundredths of a millimeter accuracy and rotates it into position with thousandths of a degree accuracy.

Once on the bending line, the upper and lower beam clamp the workpiece and the bending beam bends it up or down to any desired angle. The patented bending process results in scratch-free forming of even sensitive materials and eliminates tool wear. Envelopes, radii and special bending shapes are feasible without special tools.

When bending is complete, the main manipulator pulls the bent part all the way back. The belts of the finished part discharge lift the bent part above the table surface and convey the bent part toward the suction measuring table. There, the suction cups of the Palletizer suction frame can dip into the finished bent part. If necessary, the suction cup positions can be adjusted manually in just a few steps. The suction cups pick up the bent part and lift it. The palletizer swivels 180 degrees and moves over one of the pallets provided. A lifting movement allows the palletizer to place the bent part horizontally on the pallets. Slight angular positions are also possible so that interlocked stacks can be formed.

The equipment package of the Ecoauto bending center includes a complete set of tools for the upper beam, bending beam and lower beam. Also included is a set of swivel foot corner pieces for turning in and out of already bent side legs. A tool changer automatically sets the segments of the upper cheek tools to position. The tool changer can set up tools either symmetrically or asymmetrically to the center of the machine, which is necessary for off-center clamped (for example due to a window cutout) or angled bent parts.

The Eco version can also be supplemented with one-click programming of the bent parts. The programmer drags and drops the existing step file of the bending profile into the Bendex software. The bent part is programmed with a single mouse click. If the software finds alternative bending options, it automatically evaluates the variants and suggests the best bending strategy with a 5-star ranking. If the operator wants to check the bending sequence in advance, he can do so using a 3D simulation. However, it is also possible to go one step further and make the software available to the designer of the components so that he can check in advance whether his ideas can be implemented on the machine.

Technical support is an important feature especially in the early stages. The equipment package therefore includes free online support for service and application questions in the first year. In order to be able to benefit from future further developments of the software, a software update package of the Bendex Office software can be purchased.

© RAS

Mega UpDown Swivel Bending Machine

The Megabend swivel bending machine shows how convenient precise up-down swivel bending of sheet steel up to 6 mm or stainless steel up to 4 mm can be. The Bendex graphics software programs the bending sequences automatically. The stop system with fingers and squeegees allows automatic follow-on bends.

The technology of Megabend with Bendex graphic software combines automatic programming of bending sequences, fast machine set-up and comfortable and efficient bending sequences up and down, without the need to turn the bent parts.

Large-area bent parts, which are difficult and labor-intensive to process on die bending presses, are particularly suitable for the Megabend UpDown swivel bending machine. The cut or lasered blank can be fed from the bending beam side or the stop side. The fence consists of a combination of very stable fence fingers and separately controlled suction bars with 8 suction cups each.

The stop fingers position the workpiece on the bending line and the squeegees hold the bent part in the bending sequence so that subsequent bends can be made without operator intervention. The fact that only one stop is made per side of the bent part prevents stop errors and significantly speeds up the bending process. There is no need to turn the sometimes large and heavy sheets and the flat bent part remains on the stop throughout the entire process. This allows one person to bend even large and heavy parts alone.

The extended T-stop provides great support even for large-area bent parts. When working from the stop side, the suction bars pull the finished bent part to the rear for convenient removal by the machine operator.

Normally, the bending parts are positioned on the bending line with several stop fingers. However, individual fingers can also be locked on boards with a wavy outer edge. When bending narrow and long bent parts, the Bendex bending software uses one of the two pop-up angle stops to ensure that the blanks can be aligned safely. As another option, the bending beam can be swiveled to 90 degrees and thus used as a stop. All alternatives calculated the software suggests the best bending variant.

The position of the forward and backward stop fingers defines the position to the bending line. To ensure that the position to the right and left also matches the set-up molds, the ViN (Virtual Navigator) uses a laser beam to indicate the lateral insertion position. The ViN is an arm mounted on the upper beam that can travel along the entire working width of the machine. The software calculates the position of the laser beam and activates the ViN each time the bent part is inserted.

The weight-reduced tools of the upper beam facilitate setup. The tools of the upper beam and bending beam are clamped automatically in the tool holder. This means that a tool change can be carried out in seconds. RAS attaches great importance to the open areas in front of and behind the molds. Because: More free space means more bending possibilities. In most cases, a single set of top-cheek tools is quite sufficient for a customer’s entire range of parts. As a special feature, SnapTool_corner tools are available with a foldable sole. They automatically emerge from lateral legs, thereby releasing the bent part.

The top beam moves by a combination of spindle drive and PowerBoosters. On the one hand, this enables it to achieve high speeds. On the other hand, it can securely hold the sheets with 120 tons of clamping force during bending and provide impressive reserves of force when compressing envelopes. Due to the 850 mm opening height of the upper beam, very high tools can be used. Available tool heights range from 200 mm, designed for 6 mm sheet thickness, to 400 mm high tools for 3 mm steel sheet. A scanner automatically detects the tool height used, preventing human error when changing tool heights.

Several tool widths are available for small and large Z-dimensions on the bent part and for thin or thick sheets. When changing the bending direction, the bending beam must oscillate around the width of the bending beam tool. In the past, mechanical pendulum blocks or grid plates were used to limit the pendulum distance, and these had to be changed at great expense. With the MegaAbend, the software controls the pendulum movement and thus completely eliminates this setup effort.

An intelligent crowning system ensures straight bending results. Depending on the material type, the sheet thickness used and the bending length, the software determines and controls the crowning of the bending beam for each individual bend.

Whether an UpDown swivel bending system is suitable for flexible requirements and small production batches depends crucially on its software – in other words, how quickly and easily a bent part can be programmed. Here, the RAS Megabend sets completely new standards. Although the machine can also be programmed in the workshop, this work is usually done on the office PC in the office.

After importing a step file of the bent part or alternatively a Dxf or Geo file, it only takes one mouse click and the Bendex software programs the complete bending sequence automatically. Thanks to a data link to the machine, the programming is realistically based on the current machine parameters and the available tooling. If there are several ways to bend the part, the Bendex software will suggest the best bending strategy with a 5-star ranking here as well. A 3D simulation already shows in the office the later process on the machine and draws attention to possible collisions.

The generated bending programs can be saved in program libraries or sent to the machine as a job list. At the machine, the Bendex software gives the operator the appropriate instructions at each bending step on the two swiveling 24″ touch monitors.

© RAS

What makes a beading machine intelligent?

The RAS EasyFormer intelligent beading machines learn from the operator how to bead and crimp. This leads to repeatable parts in the simplest way. Anyone who uses beading machines in chimney construction, insulation, for ventilation components, in the tinsmith trade, in tank construction, for hydraulic pipes or in body shops is well equipped with the RAS EasyFormer.

According to RAS, the application is child’s play. Once the user creates the first part, he presses the “Teach” button (learning mode). The touch control then automatically registers how the part is created. The operator first moves the top roller down until the cylinder is clamped between the tools. With the foot switch, he now starts the rotation of the rollers. He controls the speed via the foot pedal as if driving a car: little pressure means slow and controlled forming, stepping on the foot pedal more strongly increases the speed up to the maximum speed.

But do not be afraid! In learning mode, speed is not what matters. The touch control screen keeps the operator constantly in the picture and indicates the position of the upper roller at all times. When the bead is sufficiently depressed, the operator lifts the upper roller and removes the finished part.

Now that the first cylinder is finished, the operator switches to automatic mode. He places the workpiece at the stop and starts the program with the foot switch. He can concentrate fully on the sheet metal, because the machine runs the previously learned program as if by magic. After the upward movement at the end, the rollers release the part. Since the actions are stored independently of the speed, the expert will run through the sequence at high speed, while the inexperienced can be a little more careful.

With non-revolving beads, the rolls reach their turning point with high accuracy during forward/reverse travel, which is advantageous for stiffening ribs. Continuous or stepwise infeed of the top roll gives the best forming results for thin and thick sheets.

The RAS 12.35-3 beading machine is designed for applications up to 1.75 mm steel plate, while its big brother RAS 12.65-3 manages 3 mm steel plate. The machines show their versatility through the exchangeable rollers, which are available for all conceivable tasks.

With the 7″ touch control, the entire touch surface became the screen. A clear layout provides quick access to all control functions. This shortens the learning curve for new personnel, and saving and calling up 20 possible programs takes on a whole new meaning. For example, the rolls used, the selected stop plate, the stop position and the tube diameter can be stored when programs are simply saved.

In order to open up a wide field of applications for the EasyFormer beading machines, RAS offers no less than four different stop plates. The large stop plate with 360 x 330 mm contact area is made of high-strength material with 1000 N/mm² strength. The surface is ground to provide optimum precision for users’ quality products. The fence is also split so that it can also be pushed between the rollers and allows very small fence dimensions. Furthermore, an insulating stop, a round stop and a special stop for the inclined flanging rollers are available.

Should a hazardous situation ever arise, the unique UnLock function opens the top roller of the EasyFormer 3 beading machines in a flash. To do this, the operator simply pulls one of the UnLock levers on the right or left of the machine frame. This opening is possible even in the event of a power failure or if an electrical overload has occurred.

RAS supplies the EasyFormer beading machines including roller wrench and roller container, which can be hooked into the machine base at the rear. The RAS EasyFormer beading machine can contribute a great deal to versatility in daily use. In order to cope with the countless bead shapes, a comprehensive catalog of roller pairs is available from which the customer can select the right tools for his application.

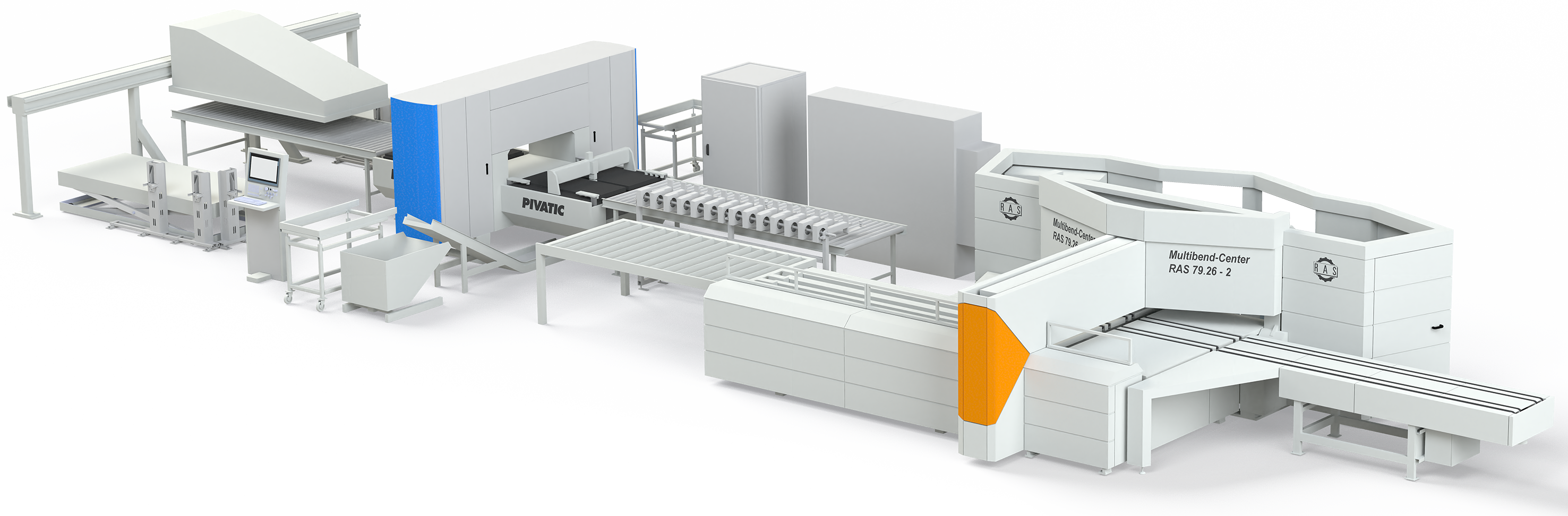

Strategic partnership

RAS Reinhardt Maschinenbau GmbH and Pivatic Oy announced a strategic partnership. As stand-alone sheet metal working systems, the performance of the RAS bending centers and the Pivatic punching lines have been known and established on the market for decades. In project-related cooperation, the two companies contribute their know-how in punching and bending and offer combined punching-bending lines.

The collaboration combines Pivatic’s punching technology with the technology of RAS bending centers to create an end-to-end production line. However, such interlinked systems are only economically viable if the punching and bending speeds are largely synchronized in time. Otherwise, the faster component always waits for the slower one.

Interlinking always results in a finished bent component after one pass and no stock of semi-finished products accumulates between punching and bending. The automated processes reduce human intervention and eliminate damage during handling.

Punching can start on the Privatic punching lines either from coil or from blanks. Unlike classic die-cutting machines, the material moves through the Pivatic die-cutting system only once. All holes and notches are created in a single pass. All tools are active and activated by a clever algorithm. The change from one tool to the next takes place in a fraction of a second. The result is a die-cut board that Privatic says is created faster than any other flexible die-cutting solution.

For loading, Pivatic offers automatic coil changing systems or can realize the connection to a high-bay warehouse. A feeder system loads the punching line with individual blanks. After punching, cut-to-length shears or blank turners can ensure that the punching burr in the bent part faces inward.

While the RAS bending cell is still working on the current part, the bending machine is already aligning the subsequent blank. A change from part to part thus takes only about four seconds. The tool change takes place automatically and parallel to the feeding of the next part. Both together significantly increase productivity. Bending is performed up and down with the highest precision and repeatability. The special RAS bending process leaves no scratches on the material surface and is ideal for coated materials or stainless steel. After bending, the finished panels can be forwarded to subsequent lines or automatically stacked.

What are the overall benefits of the strategic partnership?

This punching speed combined with the bending speed and flexibility of the RAS bending center results in an automated manufacturing solution that features low cycle times, high productivity, low logistics and handling requirements, high design freedom in part design, and low cost per part.

The integrated line is very compact and requires minimal hall space. It is primarily designed for automatic punching and bending of cassettes and panels. Due to the flexibility of both technologies, these modular lines are suitable for large production batches as well as for small quantities down to one piece.

Web:

www.ras-online.de

EuroBlech Hall 11, Booth B154