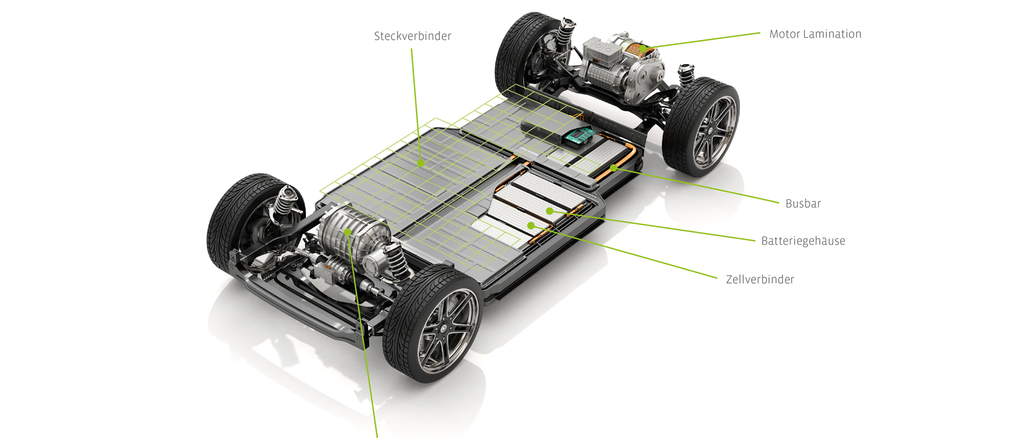

The reduction of CO2 emissions from vehicles and the achievement of climate targets are topics, Kohler contributes with its coil lines and dividing levelers to the production of important components for electric mobility and thus makes a contribution to environmental and climate protection.

In the sheet metal processing industry, the amount of sheet metal processed for the production of electrical components for the automotive industry is constantly increasing. While ever higher quality requirements are placed on electrical components or new tasks arise, the available quality of the raw material is increasingly a challenge – also for the suppliers. To meet these new requirements, strips and sheets must be straightened before further processing.

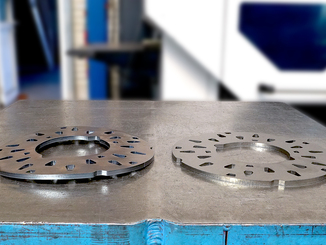

Kohler coil straighteners and part straighteners are used worldwide to precisely straighten coil material and sheet metal for rotor-stator production, battery housings, battery connectors, cell connectors and connectors for electric motors, for example. This minimizes stresses and unevenness in the material and ensures compliance with the strict specifications. In addition, the subsequent production processes benefit from the higher quality of the straightened parts and sheets, because manual and time-consuming reworking is no longer necessary.