Dreefs GmbH Schaltgeräte und Systeme, a traditional company based in Marktrodach, Germany, has established itself as a leading manufacturer of electromechanical switches since it was founded in 1903. Dreefs has been part of the Everel Group since 1996 and has specialized completely in the production of contacts for all types of electromechanical switches since 2008.

© Kohler

With an annual turnover of 9 million euros and 23 employees, Dreefs produces around 500 million contacts annually at maximum capacity utilization, mainly with welded silver contacts for electromechanical switches used in various industries such as household appliances, automotive, garden, outdoor and healthcare.

Dreefs’ modern machine park comprises nine automatic punching presses from renowned brands such as Bruderer, Haulick Roos and Mabu, which are equipped exclusively with Bihler welding systems and peripheral systems from Kohler and Leicht.

The automatic punching presses have a pressing force of up to 64 tons and run for around 5,000 hours a year in three-shift operation at speeds of up to 1,500 strokes per minute.

Each operator looks after 2 to 3 machines per shift. These are equipped with the latest control technology and are monitored by up to four computers with SPC (Statistical Process Control) systems. With these machines, Dreefs produces stamped and welded parts at an output of 150 to 6,400 parts per minute. This high speed is crucial in order to be able to offer customers not only competitive but also extremely attractive prices.

Dreefs mainly produces for internal production sites in Italy and Romania, which in turn count well-known companies such as Volkswagen, BSH, Miele, Elektrolux, Gorenje, Wolf, Franke, Hisense and Amica among their customers, and supplies markets in Europe, Turkey, the USA and Mexico, among others.

Dreefs mainly processes copper alloy strips for the production of switching contacts. Every year, around 800 tons of such strips and around 2,700 kilograms of silver are used for welding contacts. The material thickness varies between 0.12 and 0.8 mm, the width between 5 and 65 mm. Dreefs mainly uses horizontal unwinders from Leicht Stanzautomation GmbH to unwind the strips and feed them into the automatic punching presses. The progressive dies used are usually two to eight-fold. This achieves a production output of up to 1,100 welded parts and 6,400 punched parts per minute.

Some of the finished products are wound onto spools as continuous strips with Leicht vertical winders. However, the majority of the products are stamped as individual parts in boxes. For machines that produce class A parts, box changers are used in the paternoster system or as round plate versions from Leicht.

Welding is carried out almost exclusively using Bihler welding technology. However, the biggest challenge is to ensure perfect welding of the silver contacts to the carrier material. In order to guarantee this 100 percent, the raw material must be straightened.

© Kohler

Cost reduction through flat and low-tension belts

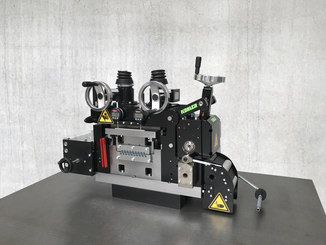

In order to achieve perfect welding results and further optimize the production processes, Dreefs decided to use a horizontal unwinder from Leicht’s PWL-150 series in combination with a CPL 120 precision straightening machine from Kohler Maschinenbau GmbH. This decision was necessary because, among other things, the carrier material for a large number of contact parts was changed from semi-hard brass to unalloyed DC01 steel for cost reasons, which made straightening and smoothing the material unavoidable.

“The integration of the compact precision straightener into the control system of the horizontal unwinder not only considerably reduced the complexity of material handling and led to significant space and time savings when placing and threading new coils, but also reduced waste and improved the welding results. The compact design of the unwinder with integrated straightener in a very small space appealed to us ad hoc.

The changeover from brass to steel strip, which resulted in material cost savings of around 90 percent, was only made possible by using the CPL 120 from Kohler. The production process could thus be made more efficient overall. Due to the excellent long-term experience with a Kohler straightening unit that has been in use since 1979, we are repeat offenders in the truest sense of the word and have once again opted for the market leader in precision straightening units for this purchase. We have had similarly good experiences with Leicht products in the area of material management. With the horizontal unwinder with integrated precision straightener, we have achieved an optimum solution,” emphasizes Harald Müller, Managing Director of Dreefs GmbH Schaltgeräte und Systeme.

© Kohler

Precise straightening results thanks to optimum roller diameter

With the CPL 120 precision straightener from Kohler, special attention was paid not only to the compact design but also to the number and layout of the straightening rollers. The 19 straightening rollers are supported by a large number of back-up rollers, resulting in high rigidity. The small roll diameter ensures that even the thin strips commonly used in the industry can be precisely straightened. Thanks to easy accessibility, cleaning of the back-up rollers and straightening rolls can be carried out quickly and easily. This protects the belt material from dust, dirt particles and damage. The machine also has a particularly rigid design to compensate for the straightening pressure.

Straightening with a high degree of plasticization even with thin belts

With the CPL 120, plasticization levels of over 70 percent can be achieved, reliably eliminating tension and unevenness in the belt material. The result is a much more stable manufacturing process of components that meet even the most stringent accuracy specifications. In addition, operating costs can be reduced because, on the one hand, fewer rejects are produced and, on the other, the punching tools have to be designed with a lower degree of complexity and ultimately achieve a longer service life.

The machine is ideal for straightening strips up to 0.8 millimetres thick and more. The settings can be made sensitively and precisely. The straightening process is constantly stable and delivers reproducible, optimum results. “In combination with the horizontal decoiler, the straightening machine is simply gigantic,” says Thomas Weber, shift manager at Dreefs.

© Kohler

High quality assurance through Industry 4.0

Thanks to the almost seamless integration of all processes in accordance with the Industry 4.0 standard and the networking of all machines via an MES system from Marposs, Dreefs can seamlessly track the entire production process down to individual contact parts and their associated boxes or coils at any time. This means that all punching and welding parameters can be continuously monitored and recorded. It is also possible to draw conclusions about the quality and quality fluctuations of the raw material and ultimately about the straightening results achieved. For high-speed production with around 800 welded parts per minute, however, a gentle material feed and optimally aligned strips before the welding process are essential.

The slightest distortion of 0.05 mm would lead to a poor welding result. This in turn could lead to a considerable risk in the final application, for example in an oven. The oven switch would melt in the absence of silver contact and, in the on position, would continue to heat the oven without being able to be switched off, which could ultimately lead to a room fire.

As part of quality assurance in accordance with Industry 4.0, defective parts are sorted out at Dreefs or the machine is stopped if there are minimal deviations from the standard process parameters. All parameters are saved and can be used for comprehensive analysis if required.

© Kohler

Relaxation all along the line

The collaboration between Dreefs and its cooperation partners Leicht and Kohler was smooth and completely relaxed. The perfectly coordinated machines from Kohler and Leicht contribute significantly to optimizing the production processes and enable Dreefs to maintain its high quality standards while increasing efficiency.

The switch from copper alloys to cold-rolled strip is currently being investigated for other products. This can result in enormous savings potential due to the lower material costs. Dreefs will continue to rely on the products and good cooperation with Leicht and Kohler when converting its processes.