Kohler has developed a new, compact precision leveler specifically designed to meet the demands of manufacturing connectors, plugs and electronic components. Users benefit from consistent straightening results even with thin coil material or deviations in strip quality. This means that production processes can be made more stable and even the most stringent quality requirements can be met.

© Kohler Mechanical Engineering

Electronic control systems are on the advance – especially in the automotive industry. On the one hand, the number of vehicles with electric motors is increasing, and on the other hand, more and more electronic assistance, safety and comfort systems are being installed in passenger cars. Connectors are needed to make these controls work. They establish contact between the individual components and transmit data, energy or signals.

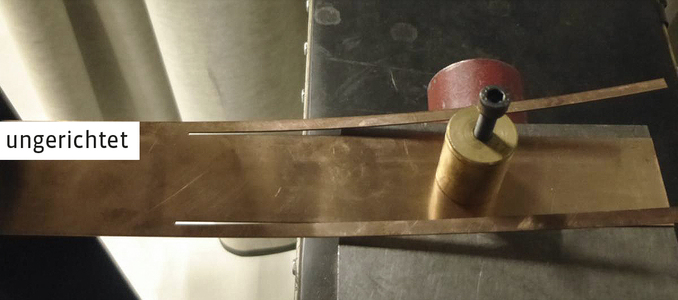

Plugs, connectors and other electronic components are often stamped from strips of copper, steel, aluminium or stainless steel sheet wound on coils. To eliminate existing stresses in the material, the strips must be straightened before punching and forming.

However, most straightening machines are not suitable for the high precision requirements of the industry: The straightening rolls are too thick for the low strip thickness and the stiffness of the machines is not sufficient to plasticize the material sufficiently.

The consequence is that inadequacies in the material are attempted to be remedied with ever more complex tools. In addition, there are inaccuracies that can lead to problems in downstream processes such as electroplating or overmoulding with plastic. Also, the high accuracy required by connector manufacturers often cannot be achieved in this way.

Precise straightening results thanks to optimum roller diameter

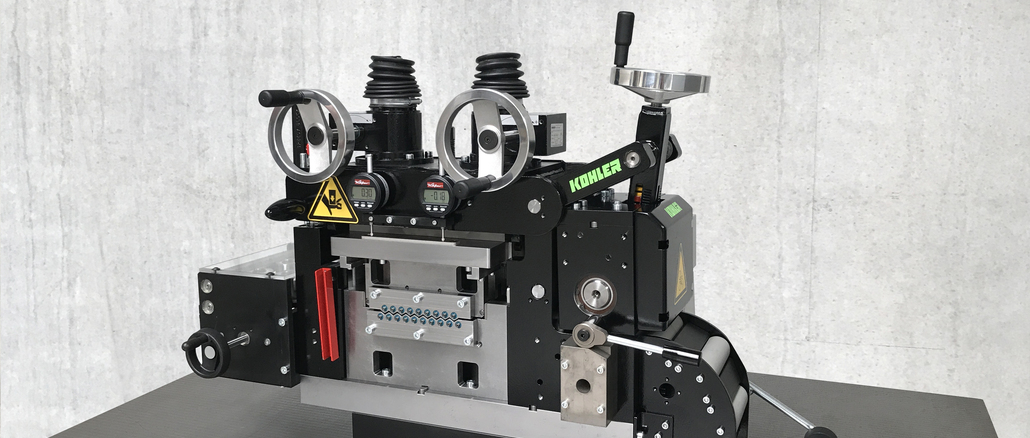

Kohler is launching the CPL 120, a compact precision leveler that is precisely adapted to the requirements of connector manufacturing.

Special attention was paid to the straightening rolls: The straightening machine was equipped with 19 hard-chrome plated straightening rolls, which are supported by a high number of back-up rolls, thus achieving a high rigidity. The small roll diameter ensures that even the thin strips commonly used in the industry can be precisely straightened.

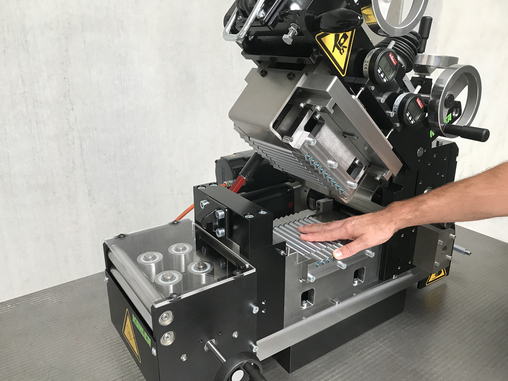

Thanks to easy accessibility, cleaning of the back-up rollers and straightening rolls can be carried out quickly and easily. This protects the belt material from dust, dirt particles and damage.

To compensate for the straightening pressure, the machine has a particularly rigid design.

© Kohler Mechanical Engineering

© Kohler Mechanical Engineering

High degree of plasticization even with thin belts

With the CPL 120, plasticizing degrees of more than 70 percent can be achieved, reliably eliminating stresses and unevenness in the coil material. The result is a much more stable manufacturing process of components that meet even the most stringent accuracy specifications. Users can also reduce their operating costs, since on the one hand there is less scrap and on the other hand the punching tools can be designed with a lower degree of complexity and ultimately longer service lives are achieved.

First users are already enthusiastic about the CPL. “The machine delivers what Kohler promised,” explains Alexander Frank, Head of Stamping Technology at Schröder & Bauer Werkzeugbau Stanztechnik GmbH + Co. KG. “There are worlds between a simple straightening stand and a Kohler precision straightening machine. For straightening strips up to 0.8 millimeters thick and more, the machine is simply ingenious. The adjustments can be made more sensitively and precisely than with other models. Thus, the straightening process runs constantly stable and delivers reproducible optimal results.”

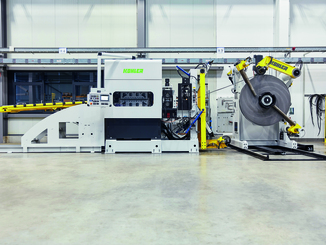

Also available as complete system

Kohler’s newly developed compact precision leveler can be supplied as a complete system with horizontal decoiler or vertical decoiler for different coil weights. Kohler also supplies the appropriate machine control system at the customer’s request.

Thanks to its space-saving design, the machine can be easily integrated into existing unwinding and production systems, which to date have operated without a straightening machine. In this way, every user can permanently improve his product quality even afterwards.

© Kohler Mechanical Engineering

Facts about machine and straightening material:

Leveler:

– torsion-resistant design

– Number of straightening rolls: 19, all straightening rolls supported

– Minimum and maximum belt width: 10 to 120 mm

– Minimum and maximum belt thickness: 0.1 to 2 mm

– Maximum tape cross-section: approx. 190 mm2

– Minimum and maximum yield strength: approx. 200 to 600 N/mm²

– Minimum and maximum belt speed: 5 to 30 m/min

– Surface treatment of the straightening rolls: hard chrome plated

Guidance material:

– Copper, steel, aluminium, stainless steel, fully or partially refined strips with precious metals

– Belt thickness: maximum 2 mm

– Belt width: maximum 120 mm

– Tensile strength: 200 to 600 N/mm2

Reel:

– Available with driven horizontal or unwound vertical reel

– For unwinding coils directly from the pallet

– Universal, particularly high-quality equipped pallet unwinder

– Contactless speed control via ultrasonic sensor

– Reversible winding direction

– Robust machine body with high load capacity

– Available in different sizes due to modular design

– Further equipment optional