This year Kohler Maschinenbau is again present with two booths at the EuroBlech trade fair in Hannover. Visitors can look forward to innovations both in the field of strip straightening systems and in the field of parts straightening machines.

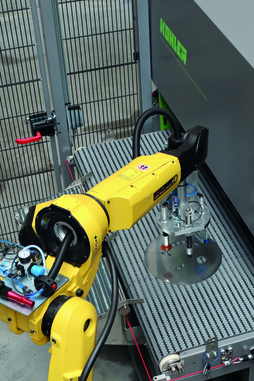

Loading and unloading of parts straightening machines is an activity that can be automated very well with a robot, especially for large batch sizes. Because while the actual part straightening is often done in a few seconds, the handling of the parts in the entire straightening process often takes the most time. Therefore, personnel-independent work brings numerous advantages: a robot can take over monotonous tasks, while skilled personnel perform more demanding work during this time.

© Kohler

A robot can also take on an additional 3rd shift or make up for anticipated staff shortages if necessary. Here, Kohler offers an attractive automated parts handling solution for parts straighteners that not only increases efficiency, but also reduces costs in ongoing operations and increases the flexibility of work processes at the same time. This solution will be on display in Hall 11, Booth B13.

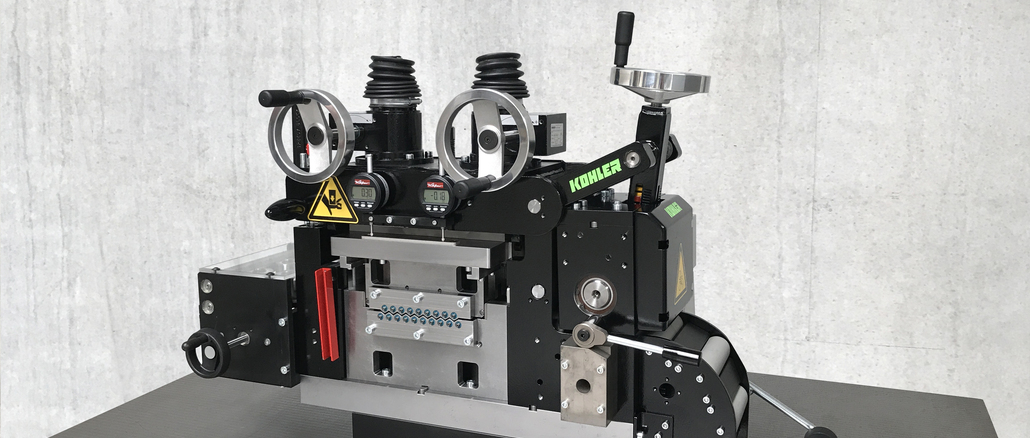

Straightening for the connector industry

Kohler has developed a compact precision leveler specifically designed to meet the demands of manufacturing connectors, plugs and electronic components. Users benefit from the straightening results even with thin coil material or quality deviations.

Special attention was paid to the leveling rolls: The straightener was equipped with 19 hard-chrome plated straightening rolls supported by a high number of back-up rolls, thus achieving high rigidity. The small roll diameter ensures that even the thin strips commonly used in the industry can be precisely straightened. The straightening mascnine is shown at the second Kohler booth in Hall 27, Booth D71.

Euroblech Hall 11, Booth B13, and Hall 27, Booth 71