Roemheld has redesigned the tried-and-tested curved clamping elements.

The robust, double-acting hydraulic component is used to clamp tools with straight clamping edges.

The clamping technology experts have simplified and accelerated production – while maintaining the same high quality.

Customers also benefit from a slightly lower price.

Among other things, the clamping element is suitable for dirty and hot environments on press tables and rams in sheet metal forming.

A special, long-term corrosion-resistant coating process ensures very good sliding properties.

As a result, the bolt releases effortlessly even after the toughest applications.

High operational and process reliability

The component gets its name from the curved clamping bolt, which clamps the tool by placing it on the straight clamping edge.

During this movement, the horizontally acting force is deflected and hits the clamping surface almost vertically.

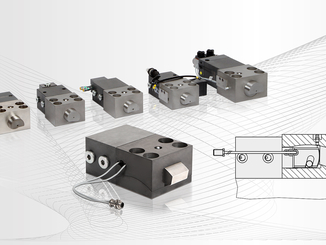

The bow clamp is available in seven different versions.

They are each available in versions with or without position monitoring for particularly high process reliability.

This informs the operator whether the bolt is clamping or releasing the tool and whether the clamping position has been exceeded.

Models with position monitoring are generally available for temperatures up to 100 °C, but can also be designed for temperatures up to 250 °C for special applications with sequence valve control.

If this equipment option is omitted, the upper limit is generally 250 °C.

An integrated mechanical locking bolt holds the upper parts of the tool reliably, even in the event of a pressure loss, so that they cannot fall down.

The clamping and release pressure is 200 bar in each case, the clamping force varies between 30 and 450 kN depending on the model, and the maximum permissible process force is 620 kN.

Web: www.roemheld.de