At Euroblech, Roemheld will be presenting various innovations that help to optimize set-up times on presses and punching machines.

A new hollow piston cylinder celebrates its trade fair premiere.

It can be used for tools with clamping rims of different heights, to which it can be flexibly adapted.

Also new are pull-push chain systems with several control options, which are offered in various standardized versions as “plug & play carefree packages”.

Also on show for the first time is a bow tensioning element that has been redesigned.

Another highlight is the large range of tool changing trolleys.

© Roemheld

Innovative hollow piston cylinder for tools with different clamping edges

The new hollow piston cylinder clamps tools with clamping rims of different heights.

This makes work easier in all forming operations, especially for contract manufacturers who have to work with different, non-standardized tool clamping rims.

According to the manufacturer, the unrivaled element can be used for clamping rims with a level difference of up to 30 mm.

The required height can be set in steps of 1 mm.

The new hollow piston cylinder offers clamping forces of 60 or 100 kN and can be used at operating pressures of up to 400 bar.

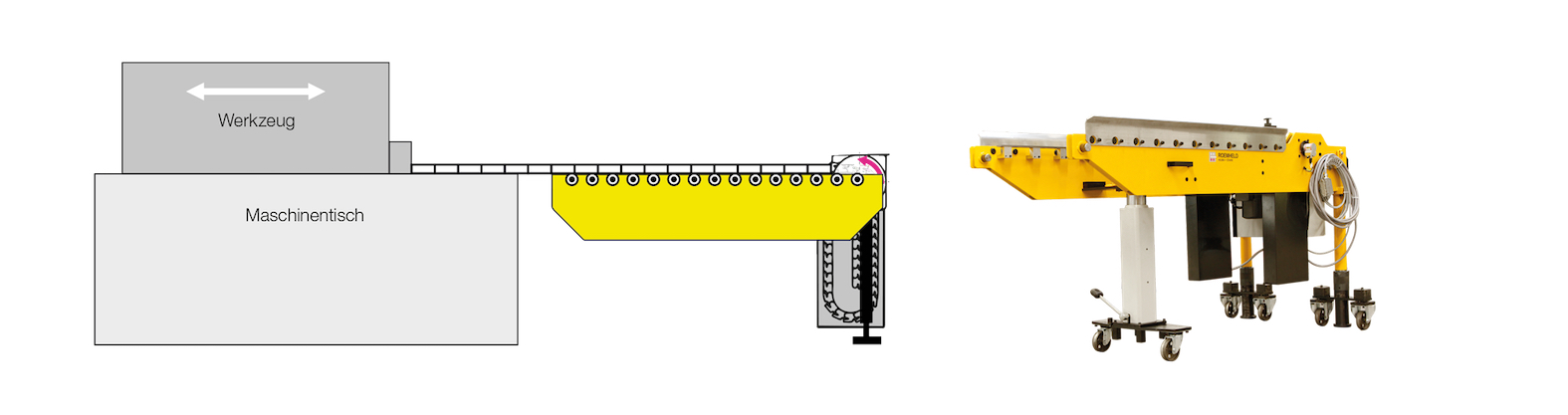

From a single source: New push-pull chain system for plug & play

The new pull-push chain system for loading presses and punches is suitable for almost all application scenarios and tools up to 40 tons.

It can be installed either directly on the system or on a rail-bound transport system.

Alternatively – for loading by crane – it can be integrated into a manually or electrically driven tool changing console.

The pull-push chain system is available as a complete solution in various standardized versions and with different control variants.

As all components are coordinated with each other, the manufacturer promises a carefree and quick installation via “plug & play”.

New sheet clamp for high operational and process reliability

For the first time at Euroblech, Roemheld is exhibiting the new, redesigned bow clamp for tools with straight clamping edges.

It is suitable for dirty and hot environments up to 250 °C on press tables and rams in sheet metal forming, die casting and forging applications.

A special, long-term corrosion-resistant coating process ensures very good sliding properties.

The bolt therefore releases effortlessly even after the toughest applications.

The bow clamp is available in seven versions, each with or without position control for particularly high process reliability.

An integrated mechanical locking bolt reliably holds the upper tool parts in place even in the event of pressure loss.

© Roemheld

Large range of trolleys for changing tools

The extensive range of transport trolleys for tool changing includes models for loads between 500 kg and 40 t. It ranges from manually movable models with small turning radii for narrow aisles and short distances to larger free-moving versions for loads of up to 8 t and rail-bound systems that connect different halls with each other.

Smaller models are available with or without an integrated auxiliary drive.

All transport trolleys offer a standardized docking system adapted to the respective press, which ensures safe transfer of the tool to the machine.

Hydraulically lowerable ball bars on the transport surfaces make it easier to move the tools.

Euroblech Hall 27, Stand K65 Web: www.Roemheld.de