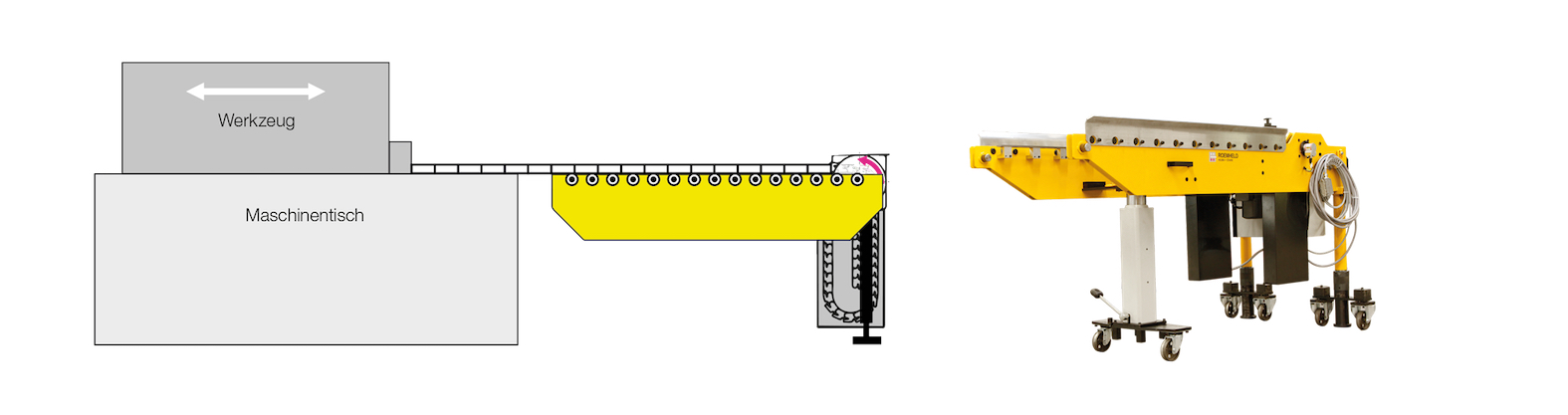

Roemheld has introduced a new manually traversing changing console for tools weighing up to 50 tons. The space-saving innovation expands the company’s extensive range of components for setup time optimization in sheet metal forming. It is designed for all users who want to change forming tools of all weight classes in a time- and force-saving manner, for example automotive manufacturers and their suppliers.

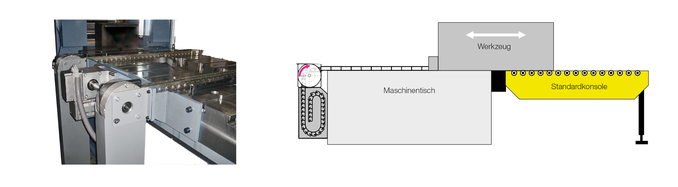

The console, which is electrically driven via a push chain drive, has a particularly compact design and can easily be used on low press tables and in difficult-to-access environments. It can be mounted alternately on different presses and easily integrated into partially or fully automated processes.

The innovation combines a standard tool change console with an electric push chain drive. It is available in different versions and is suitable for almost every type of press – both for new plants and for retrofitting. In addition, customized mold set-up and change systems can be realized with individual special solutions.

© Roemheld

Change heavy molds easily and safely on multiple presses

With the new changing console, users can easily and safely change heavy molds on presses. Lowest support heights are possible, so that it can be used even with deep press tables. Optionally, it is available as a mobile unit with castors and can then be easily moved and transported between different plants. Once at the press, an integrated docking system ensures that the console unit is firmly seated on the press.

The mold is then placed on the console by forklift or crane. The integrated push chain drive then moves it to its final position in the press via integrated roller and ball bars and positions it there with millimeter precision even against fixed stops.

Semi or fully automatic operation

Optionally, the mold can be inserted semi-automatically or fully automatically; speeds of up to 2 m/min are possible. The degree of automation of the mold change can be freely determined, and individual sensors and stops can be integrated into the control system. The changeover console is operated either via the press control system or via a separate control system, which is available as an option.

Setup time optimizer for sheet metal forming, plastics and rubber processing

Roemheld sees itself as the worldwide market leader in tool clamping technology for sheet metal forming. As a set-up time optimiser, the group of companies solves almost every clamping task in sheet metal forming, plastics and rubber processing with its extensive portfolio of mould clamping technology. The magnetic, hydraulic and electromechanical clamping systems can be used in a wide range of applications and help to make the processes in individual and series production in almost all branches of industry more efficient and economical. Products for tool change, including tool change carts, roller bars and driven support brackets, round off the range.