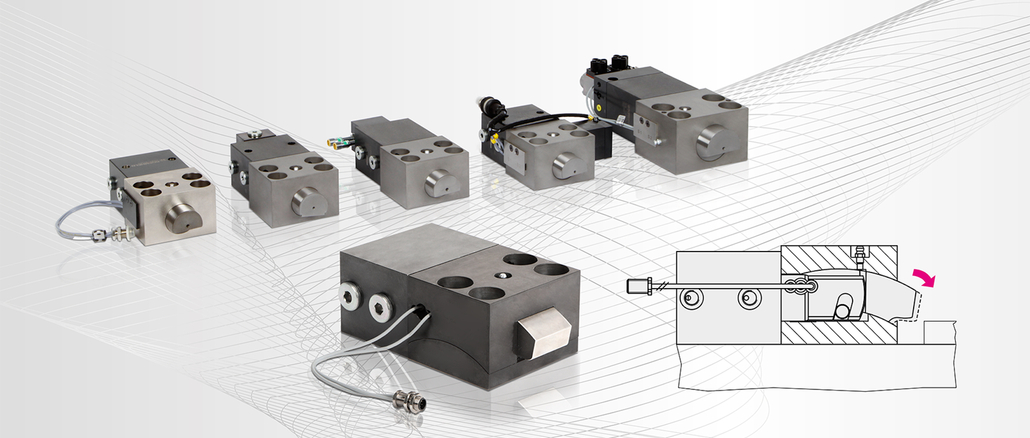

According to the manufacturer, the new sheet clamp is particularly robust and safe for use on presses and forges. With it, the clamping technology specialist Roemheld expands its many-headed wedge clamps family.

An integrated mechanical lock reliably holds the upper part of the tool in position in the event of a pressure loss. That way it can’t fall off. Thanks to a special coating process, the tool clamping element does not corrode even under the toughest conditions. Due to the arc-shaped force progression of the clamping bolt, jamming at the clamping point is virtually ruled out.

Double acting and with position control on request

The double-acting arch clamp is designed for a wide range of applications with straight clamping edges. It is suitable for high clamping edge tolerance of ±1 mm. Clamping and release pressure are identical at 200 bar and provide a maximum clamping force between 30 and 450 kN and process forces up to even 620 kN.

There is also a choice of variants without and with position control for particularly high process reliability. The additional equipment is integrated laterally on the clamping bolts to save space. It provides information on whether the bolt is clamping or releasing the tool and whether the clamping position has been overrun.

The clamping element takes its name from the arc-shaped clamping bolt with which the tool is clamped.

Set-up time optimizer for sheet metal forming

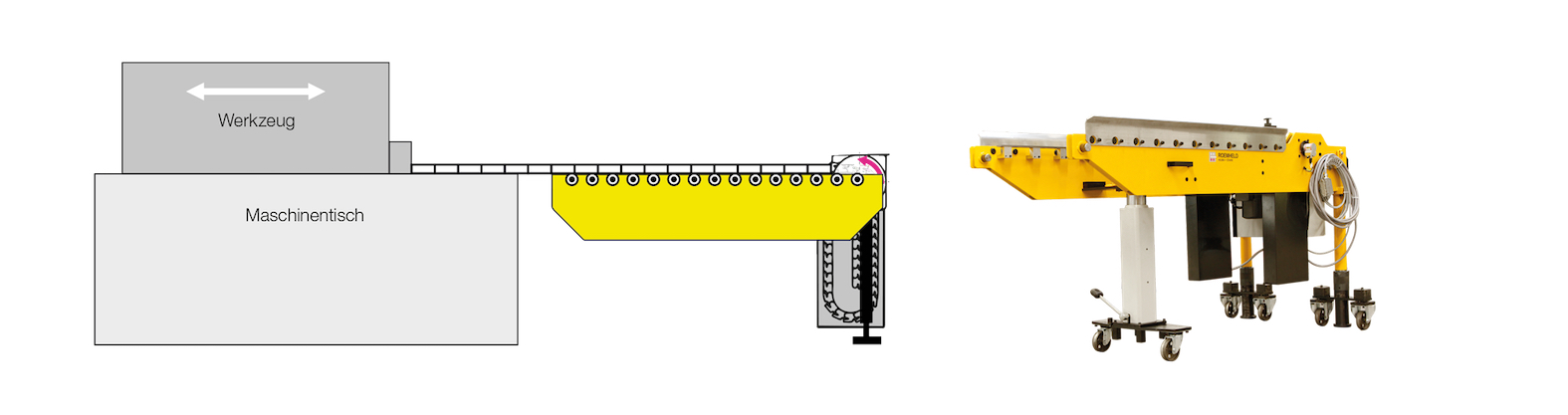

Roemheld sees itself as the worldwide market leader in tool clamping technology for sheet metal forming. As a set-up time optimiser, the group of companies solves almost every clamping task in sheet metal forming, plastics and rubber processing with its extensive portfolio of mould clamping technology. The magnetic, hydraulic and electromechanical clamping systems can be used in a wide range of applications and help to make the processes in individual and series production in almost all branches of industry more efficient and economical. Products for tool change, including tool change carts, roller bars and driven support brackets, round off the range.

About Roemheld:

Whether airplanes, automobiles, machine tools or housings for smartphones: Roemheld technologies and products have been used in the production of numerous industrial goods and goods for the end consumer for more than 60 years.

Innovative and smart clamping technology solutions for workpieces as well as for tools in forming technology and plastics processing form the core of the constantly growing portfolio. It is complemented by components and systems for assembly and handling technology, drive technology and automation, as well as locking systems for wind turbine rotors.

In addition to a constantly growing range of more than 30,000 catalogue articles, Roemheld specialises in the development and manufacture of customised solutions and is internationally regarded as one of the market and quality leaders.

Innovation through tradition: Roemheld has its origins in the Friedrichshütte foundry, founded in 1707, which still belongs to the Roemheld Group today and is one of the oldest active industrial companies in Germany.

The owner-managed group of companies employs around 560 people at its three sites in Laubach, Hilchenbach and Rankweil (Austria) and is represented by service and sales companies in over 50 countries. With customers in particular from the mechanical engineering, automotive, aviation and agricultural industries, Roemheld achieves an annual turnover of more than 100 million euros.