Sharply calculated prices and top quality are no longer enough – medium-sized suppliers now often have to quote their customers the product-specific carbon footprint in addition to the parts price. In order to meet this requirement, Peter Thielen Industrieberatung has further developed its Calcstar software for this purpose.

© Mühlhause GmbH

The major automotive manufacturers (OEMs) in particular, and thus also the major system suppliers at Tier1 and Tier2 level, require their suppliers to document the product-related carbon footprint (PCF) as early as the bid submission stage. Both for the material used and for the individual manufacturing processes, supplier companies must determine and disclose the CO2 emissions. However, not all raw material and supplier suppliers provide the data on the CO2 generated. The calculation of emissions can therefore be very time-consuming.

Meanwhile, several freely accessible databases offer extensive information. For example, the German Federal Environmental Agency has an extensive collection of data available in Probas (https://www.probas.umweltbundesamt.de/php/index.php).

CO2 amount already recognizable in product design

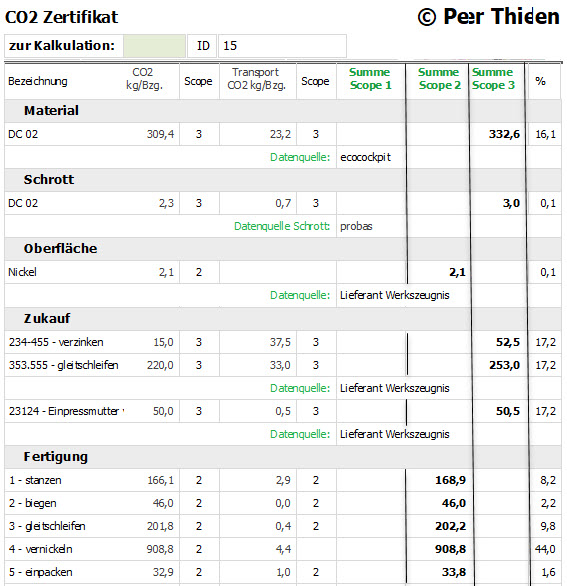

Peter Thielen Industrieberatung from Menden in the Sauerland region has already included such data on CO2 emissions in its Calcstar calculation program. This makes it possible to identify which materials, accessories and work steps generate which CO2 emissions as early as the method planning stage. Users can thus search for more environmentally friendly manufacturing options.

In sync with the quotation calculation, Calcstar creates a CO2 certificate in which the individual values are assigned to the categories for Scope 1 to 3. In this way, the calculator reaches its goal with one click and saves time-consuming double calculations. Separate calculations of part price and CO2 emissions from different sources are no longer necessary.

One user that has been using the CO2 calculation integrated in Calcstar for a long time is Mühlhause GmbH in Velbert. The specialist for stamping and forming technology works independently of the industry and attaches great importance to accompanying its customers through the entire process of their projects. Of course, this also includes calculating the carbon footprint.

Managing Director Dirk Mühhause is convinced of the process: “The use of this CO2 tool – apart from customer requirements – is also a personal concern of mine to make CO2 generation in production visible and measurable and to counteract it in order to make an active contribution to climate improvement!”

© Peter Thielen

Calculation method determines company success

The Calcstar calculation software can do much more. “If you want to avoid loss of earnings in the turbulent cut-throat competition, you can hardly manage without a transparent, meaningful calculation method,” explains Thielen.

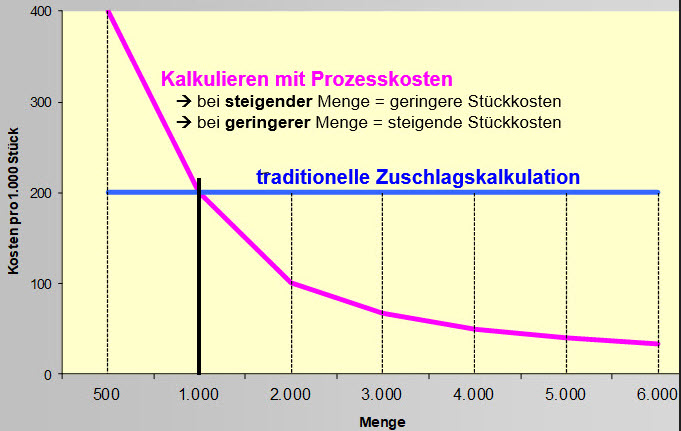

In his seminars, which he has recently held at the Industrieverband Blechumformung (IBU) and also at the Deutscher Federnverband (VDFI), among others, he advocates optimizing traditional overhead costing. In doing so, he points out that the markup of value-based, percentage overhead rates leads to incompatible price distortions: Larger series are overpriced, while small orders are offered at subsidized rates. On the other hand, those who calculate their bid prices with process costs that are more appropriate to the cause improve their chances of acquiring lucrative orders.

Thielen has another suggestion at the ready: a contribution margin calculation should be created in parallel to the usual overhead calculation. The direct comparison of both costing methods makes it easier for price managers to decide on the still acceptable lower price limit in difficult price negotiations.

© Peter Thielen

Determine process times in the administrative area

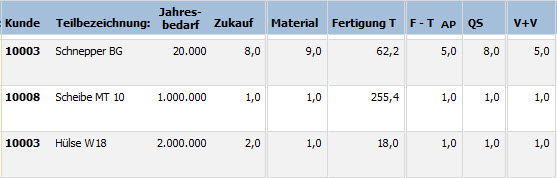

With Calcstar, the necessary process times in the administrative areas such as in work preparation, quality management and materials management as well as in the often costly administrative and sales areas can also be calculated to the hour. Thielen: “In manufacturing, it has been common practice for decades to determine the time required for each operation down to the minute. Now, controllers can take a close look at all administrative areas to see where there is potential for rationalization.”

Stéphane Itasse, freelance trade journalist

Web:

www.thielen.biz