In the construction machinery industry, the LiuGong brand is a household name worldwide. Wheel loaders, excavators or bulldozers are sold through 300 dealers in more than 100 countries. Large-format and heavy semi-finished products are often processed for the production of machines designed for heavy loads. For this, LiuGong relies on MicroSteps MG with a large machining area and technologies for precise and dimensionally accurate weld preparations.

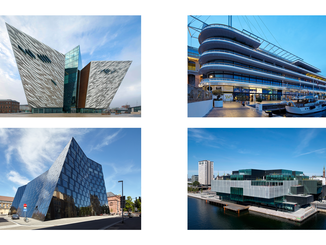

© MicroStep Europe

“Tough World. Tough Equipment.”: With this slogan, Chinese manufacturer LiuGong designs and produces a wide range of construction equipment. Founded in 1958, the company is one of the 500 largest in the People’s Republic and offers wheel loaders as well as hydraulic excavators, bulldozers, dozers, rollers or truck cranes. Many of the products are designed for heavy and strenuous work, accordingly, thick and large-format materials are also processed.

In order to cut the appropriate flat material for this purpose, the large construction machinery manufacturer relies on cutting technology from MicroStep. A 3D plasma cutting system kicked off the collaboration in 2019, followed by another one a year later. Now, two CNC cutting systems from the MG series are reliably performing their services, reducing manual rework, helping to cut costs, and at the same time ensuring faster processes. At the same time, both CNC machines have an extraordinary machining area. The first line can accommodate sheets on a work surface of 24,000 x 3,500 mm. It is equipped with a plasma rotator for bevel cutting up to 50° and relies on a HiFocus 440i neo from Kjellberg Finsterwalde as the plasma source. The more recent system also has Kjellberg technology connected (HiFocus 360i neo) and, at 28,000 x 3,500 mm, even a longer worktable – and it is configured as a double-port system. Both portals are equipped with one plasma rotator each.

Investment pays off quickly

In the process, the top management did not make it easy for itself in the search for the right solution that would also maintain the necessary tolerances across larger cutting jobs. “LiuGong has to machine and cut sheets up to 12 meters long and 2.2 meters wide for cranes. Only the MicroStep MG can machine the V-bevel within the required precision and with the appropriate dimensional accuracy,” explains Victor Zou, General Manager of MicroStep China. Thanks to the technology, the operator can adjust the value for kerf correction and the value for compensation of the chamfer by the system according to the real situation, thus maintaining the tolerances even over meter-long chamfers. “The investment quickly pays for itself financially. As we know, the price of milling the edges of parts is much higher than using the plasma cutting system.”

Web:

www.microstep.com