At this year’s Tube & Wire, BLM Group will present a variety of its solutions and its complete range of services.

“Finally, we can meet customers again at a major international trade show. We look forward to welcoming visitors to our booths, where we will show our most important technology in action. In addition, our visitors will be able to discuss with our experts which of our solutions best cover their production needs,” explains BLM Sales Manager Maurizio Toselli. “Of course, even during the difficult and uncertain Corona period, we remained in contact with our customers through various channels. But these could hardly fully replace the personal exchange of views that is elementally important for joint planning for the future.”

BLM Group will present its new solutions in Hall 5 (Booth J22) and in Hall 10 (Booth F21).

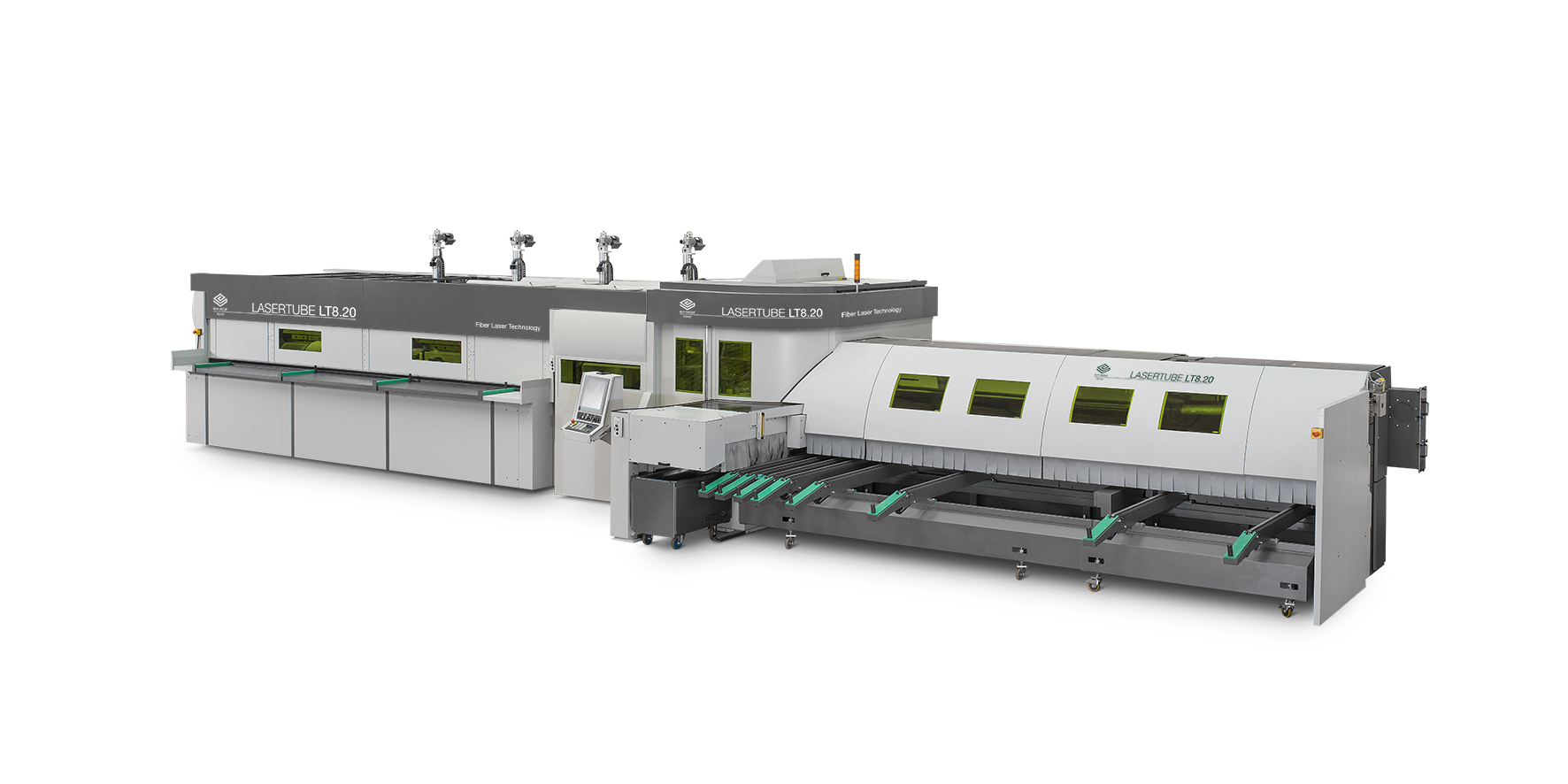

The most versatile tube laser in the Lasertube family

The LT8.20 is the BLM Group’s most flexible solution for tube laser cutting in quite a few application areas and for very different production requirements. It offers the most options in terms of its configuration, loading and unloading lengths, and technical solutions.

In laser cutting of standard tubes and special profiles with 12 mm to 240 mm diameter, it offers the largest working range with its 3D laser cutting head. Customers can flexibly determine the layout of the machine depending on the available space as well as the desired production type and work organization.

According to BLM, the LT8.20 guarantees high productivity for both large and small series. Production changes are carried out automatically and take only a few minutes. According to the manufacturer, the system offers consistent quality and performance across the entire product spectrum – regardless of the complexity of the parts or the size of the machine. Cutting path: material of any thickness and gauge, closed or open profiles, 2D or 3D laser cutting, whatever the quantities and geometries.

In addition, the LT8.20 can be equipped with the special functions of the so-called Active Tools, which, according to BLM, enable customers to achieve better results even faster – regardless of the experience of their machine operators. The LT8.20 is characterized by simple operation and maintenance.

https://www.youtube.com/watch?v=9ELpNmuW52s

© BLM Group

High-end tube laser of the Lasertube family and undoubtedly the benchmark in tube laser cutting

The LT7 is the result of years of investment in research and the continuous development of innovative software and hardware solutions. The machine is equipped with an IPG laser source with 3 kW power, automatic loading for tube bundles with lengths up to 6.5 m and an unloading system for tubes up to 4.5 m long. The LT7 produces workpieces from tubes with diameters from 12 to 152 mm and bar weights up to 23 kg/m, offering the highest performance. From the smallest to the largest diameter, the machine automatically adjusts all settings. L, U and other open profiles as well as flat bars are also standard for them and are processed fully automatically. The laser source offers great flexibility in terms of wall thicknesses and materials – from 12 mm thick steel to 4 mm thick brass. 3D cuts complete the picture of a flexible machine for a wide range of different applications.

https://www.youtube.com/watch?v=gyhOlvnfD5M&t=15s

Flexible and compact laser cutting system with robot

The LT360 laser cutting system shown is designed for fixed table cutting and is a solution for processing deep drawn, flat or stamped sheet metal. It is equipped with a 3 kW fiber laser source and a comprehensive cutting parameter database, as well as advanced technology features such as Active Focus for optimizing quality and productivity on all types of workpieces.

The LT360 is available in various configurations. The One-Flex configuration is equipped with a robot for handling the workpieces – an ideal solution for laser cutting of bent or hydroformed tubes. In the tailored configuration, the handling robot picks up parts from outside the booth, which is why the system can be integrated into a variety of different production processes.

https://www.youtube.com/watch?v=rH4mBXafRTI&t=15s

© BLM Group

Tube bending machine for today’s applications and expandable for tomorrow’s requirements

The Elect is a fully electric tube bending machine with freely programmable right and left bending and visual graphic programming with VGP3D. The settings and parameters of the bending process are stored, which guarantees high repeatability and fast production changes. In addition, B_Tools calculates the springbacks and elongations of the materials in the bending process, so that customers produce perfect parts right away after production changes.

The Elect can be configured in a variety of ways, allowing it to adapt flexibly to different requirements and be used in all work situations. This applies, among other things, to bending with a small radius-to-diameter ratio, bending with a variable radius or bending special profiles, high-strength materials or stainless steel with strong springback forces.

Thus, the tube bending machine can generally be configured and optimized for a wide range of production requirements. It can be subsequently expanded at any time to include special functions or modules in order to adapt it to changing market requirements. The Elect can be equipped with automatic bundle loading and a robot for unloading into bins or onto a conveyor belt.

The turnkey solution is available in several standard configurations where the different elements (tube bending machine, unloading robot, loading, container or conveyor) are arranged according to different layouts on the right and left of the machine to maximize productivity and make the best use of the available space.

https://www.youtube.com/watch?v=4Y2RL87EJac&t=5s

© BLM Group

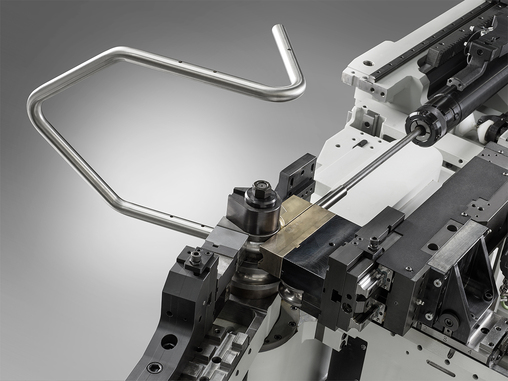

Left and right bending for the greatest variety of shapes

The E-Turn is a versatile tube bending machine and suitable for virtually any need: for right and left bending in the process with fixed or variable radius as well as for multi-radius bending. The machine can be loaded with eight tools simultaneously and position the variable radius on each plane. The E-Turn was developed to meet the growing market demand for medium to small series of complex and multi-bent tube components made of high-quality material. It is particularly suitable for complex parts without straight sections between bends.

The E-Turn compensates with B_Tools for the strains and springbacks that occur in the bending process, so that it can be used to produce perfect parts right away after production changes.

https://youtu.be/huo8crFm8bw

Work cell supplied from coil with bending with mandrel and forming of both ends

The work cell shown at the Tube with a 3-Runner, a Smart and an AST8-VE is just one of many examples of how different technology from the Group can be combined. In detail, it is a compact and highly productive work cell (more than 150 parts/hour) for processing tubes with feeding from coil (28 mm diameter copper tube).

The operations include straightening, forming and cutting to length with the 3- Runner, bending with mandrel on the Smart and forming the other end of the tube on the AST8-VE. The process, controlled by a single control point, is fully automated, using a handling robot for loading and unloading the interconnected systems. The orders are executed on the different systems simultaneously. This allows a significantly reduced cycle time, as any manual handling of semi-finished parts is eliminated and no intermediate storage is required. In the process, the 3-Runner cuts the material in such a way that it is optimally utilized and waste is reduced to a minimum. The work cell can process tubes made of any material (stainless steel, iron, copper or aluminum) and can also produce bent parts with a narrow radius-diameter ratio.

© BLM Group

A new production solution for electromobility and the energy sector

With the Smart, BLM Goup is also showing one of its most successful tube bending machines. It is equipped with hardware and software for processing uncoated flat steel for sectors such as electromobility and the energy market in general.

The Smart is a fast and efficient tube bending machine with right and left bending in a multi-radius process. Its flexibility and small bending head make it suitable for use in markets such as the automotive industry. This is also due to its reliability, which, according to BLM, “is due to the high quality of all components and the simple and efficient mechanics”. They guarantee high work performance and maximum availability of spare parts.

https://www.youtube.com/watch?v=oGC_xltsCc8

Wire bending machine with two bending heads and two bending towers for diameters up to 12 mm

The DH40 is a wire bending machine with two bending heads, each with two bending towers. It allows the production of large, complex parts either from coil or from bars. The DH40 can process a wide range of materials flexibly and productively: Wire up to 12 mm diameter, rods and small tubes, and armored heating elements for household appliances.

In VGP3D, all parameters of the production orders are saved with the part programs. No special knowledge is required for their operation and conversion.

The versatility in the feasibility of parts production is further enhanced by the cantilever and space-saving design of the bending heads, the double bending towers and the retractable manipulator – it enables the production of parts with very short spacers. Thanks to the possibility of bending wire with a diameter of 12 mm, it can be used in the manufacture of interior and exterior furnishings, among others, such as chairs, tables, stools, hangers or brackets.

https://www.youtube.com/watch?v=CkoUTb7-7Gk

© BLM Group

For easy and productive design with wire

The E-Flex is a fully electric double head wire bending machine for metal wire up to 10 mm diameter. With its space-saving bending head with planetary movement around the wire and its double tower, it performs a wide range of different bending techniques. Thus, the E-Flex offers complete freedom in the production of objects of any kind from coil – and extremely fast and repeatable.

In VGP3D all parameters of the production orders are stored with the part programs. No special knowledge is required for their operation and conversion. Its all-electric technology, its high quality components, the possibility to equip the system with tools with grooves, special tools for parts with high demands on their optical quality and a cutting system also controlled by a special electric axis to ensure the best cutting quality and a longer tool life

https://www.youtube.com/watch?v=bbf1GXEcsF4

Software solutions and services at both booths

A complete software suite to control the entire process In parallel with its laser cutting systems, BLM Group offers a range of native software solutions to help customers get the most out of their machines. They offer comprehensive functions for programming both on the machine and in the office.

Artube is the CAD-CAM software for programming the tube lasers. It allows operators to draw, edit and design individual parts or complex assemblies of tubes with any cross-section. Artube is BLM Group’s most complete CAD-CAM software, dynamic and adaptable to individual customer requirements.

VGP3D is the three-dimensional graphic programming software for the tube bending machines and the wire bending machines. The easy-to-use and powerful VGP3D software is also available as an office version. It allows customers to create any shape or geometry from tubes with just a few clicks.

Protube is BLM Group’s MES (Manufacturing Execution System) – a single interface for easy and transparent management of part programs for BLM Group’s main machines. Protube can be used to prepare technically accurate work orders in the office, plan production efficiently, send production orders to plants that are integrated into the process, and keep track of all operations.

Thanks to the use of AI strategies and integration with customers’ ERP systems, Protube is the key to developing intelligent Industry 4.0 applications.

https://www.youtube.com/watch?v=2Swu_7MjeOA&t=66s

BLM Group

BLM Group is a global partner for the entire tube processing process with a very broad installation base worldwide with thousands of applications:

– BLM SPA, Cantù (CO), specializes in CNC tube bending machines, forming machines, measuring systems and related peripheral and automation solutions.

– Adige SPA, Levico Terme (TN), produces laser cutting systems and sawing machines for tubes, solids and profiles. Deburring machines, measuring systems, washing machines and collecting containers complete the portfolio.

– Adige-Sys SPA, Levico Terme (TN), produces combination machines for laser cutting of tubes and sheets, laser cutting lines for large tubes, and machines for cutting and finishing of solid and tube ends.

Web:

www.blmgroup.com