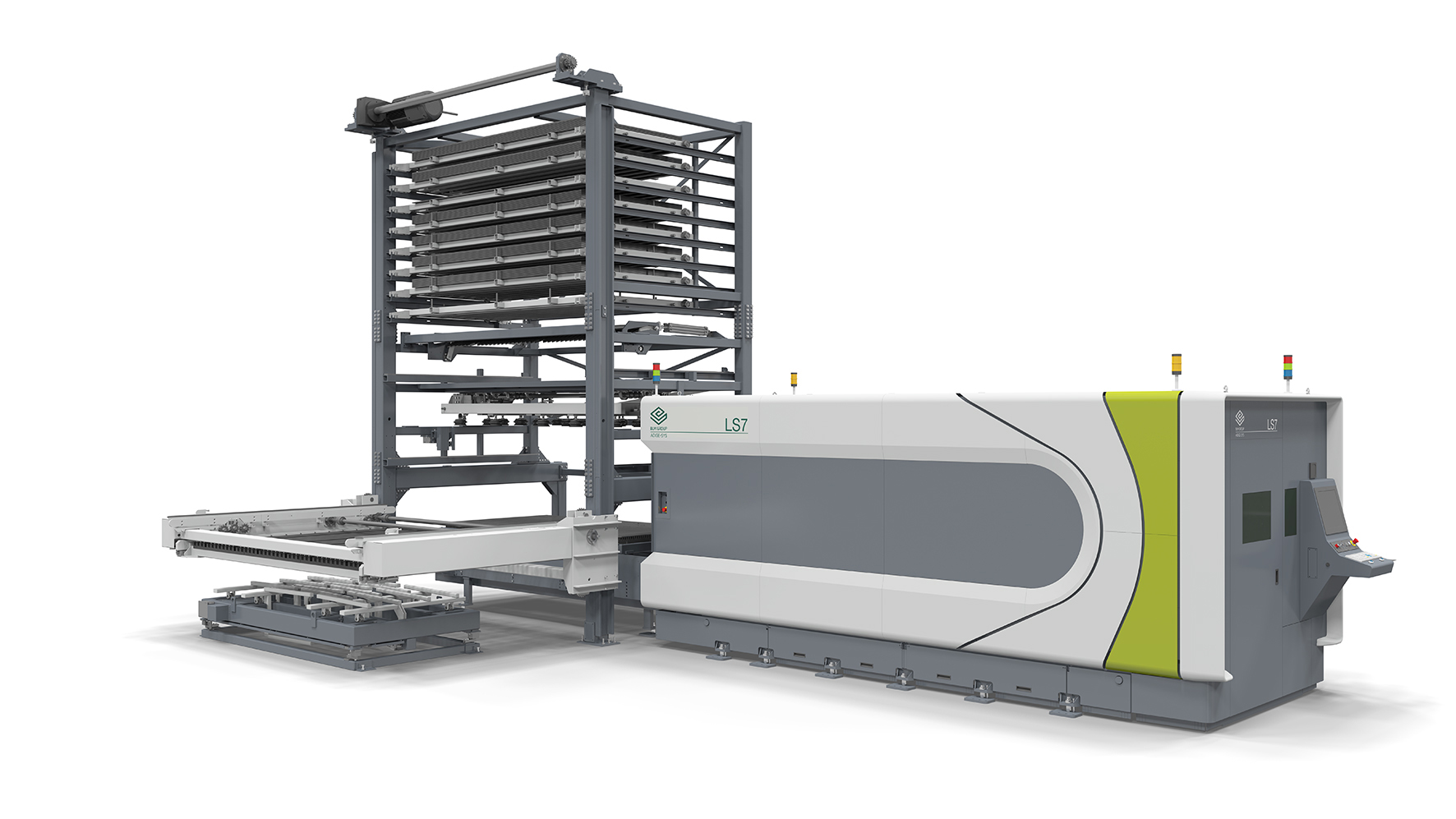

The LS7 laser cutting system has been specifically designed to meet the requirements of intensive and continuous sheet metal processing.

© BLM Group

Its main advantages lie in its high degree of automation and flexibility in production. The LS7’s sensor-equipped cutting head guarantees consistently high quality in sheet metal processing, even in unattended operation. It automatically reports when the protective glass needs to be cleaned or replaced. This saves operators from having to perform regular checks. It also ensures that the protective glass is only replaced when it is actually necessary.

The fiber source is available with different power ratings up to 12 kW and can be equipped with a variety of technical options. This flexibility in configurability gives customers the freedom to choose only the functionality they need for their production. Even the basic configuration of the LS7 is characterized by high performance and ease of use. Their lightweight design features high mechanical rigidity, which allows accelerations of the cutting head of up to 20 m/s² (2g) in sheet metal processing, while always accurately guiding the axes of motion.

According to BLM, the automatic pallet changing system is one of the fastest on the market. It speeds up production changeovers and thus increases the availability of the machine. The configuration shown at the show is equipped with a compact storage tower through which the LS7s are automatically loaded with sheet metal and the finished parts are unloaded. The tower increases the productivity of the machine and allows unattended production.

© BLM Group

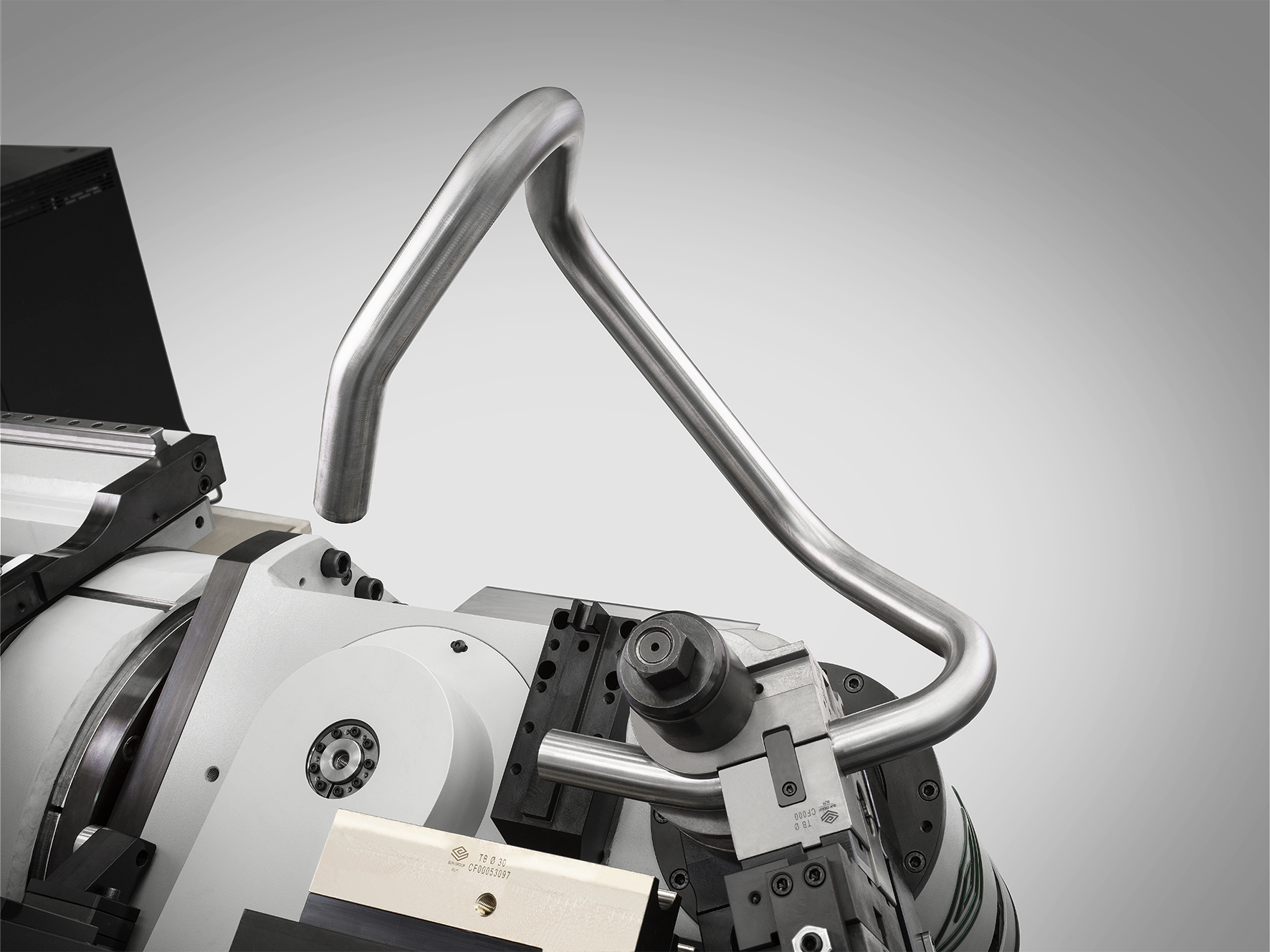

High-end pipe laser – a benchmark in pipe laser cutting

The LT7 is the result of many years of investment in technical research and continuous development of innovative software and hardware solutions. Equipped with a fiber source, the machine is available with automatic loading systems for bar lengths of 6.5 m or 8.5 m and unloading systems for workpieces with lengths of 4.5 m, 6.5 m or 8.5 m. The LT7 processes pipe with diameters from 12 mm to 152 mm and with bar weights up to 23 kg/m, delivering excellent performance across the entire working range, BLM promises. From the smallest to the largest diameter, the machine makes all adjustments automatically. Even open profiles such as L and U profiles and flat bars, among others, are processed fully automatically like standard profiles.

The fiber source is characterized by high freedom of movement and flexibly processes various material thicknesses and materials – from 12 mm thick steel to 4 mm thick brass. The possibility of 3D laser cutting completes the picture of a quite flexible system that covers very different applications. Productivity, quality, accuracy, flexibility, high level of automation and ease of operation – for all these performance features, the LT7 offers innovative solutions that are unparalleled in the market. The machine on display at Blechexpo is equipped with the innovative threaded riveting unit, which automatically inserts threaded rivets from M4 to M12. It simplifies production and saves both handling and storage of semi-finished products.

© BLM Group

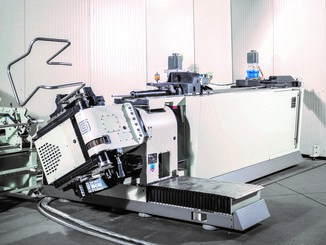

Perfect parts at the first go with the all-electric tube bending machine

The E-Turn is a highly versatile machine for right- and left-hand bending in the fixed-, variable- or multi-radius process – and thus for virtually all tube bending requirements. With it, eight tools can be mounted simultaneously and the variable arm can be mounted at any height.

The E-Turn was developed with the aim of meeting the increasing market demand for complex, versatile shaped tube components produced in small to medium quantities from high-quality materials. It is particularly suitable for the production of complex parts and workpieces without straight sections between bends. The high quality standard achievable with the E-Turn is the result of complete control over the reactions of the materials being processed and the all-electric control of the working parameters. In addition, the E-Turn with B_Tools compensates for the elongations and springbacks of the tubes in the bending process, so that customers always produce perfect products on the first try after order changes.

The E-Turn is available in different sizes for tubes up to 52 mm. It is used in the furniture, automotive, motorcycle and aerospace industries, among others, as well as in plant engineering for the production of components, but thanks to its flexibility and speed it can generally be used in all industrial sectors. The solution shown at Euroblech is ideally suited for unattended production. It complements the E-Turn tube bending machine with automatic bundle loading and a robot for unloading the bent tubes.

© BLM Group

Complete software suite for controlling the entire process

For its laser cutting machines, BLM Group offers native software solutions that enable customers to maximize the performance of their machines. These solutions offer comprehensive functionality for programming both on the machines and in work preparation.

VGP3D is the three-dimensional graphical programming software for the tube bending machines and the wire bending machines of the BLM Group. The easy-to-use and powerful VGP3D software is also available as an office version. It allows customers to create any shape or geometry from tubes with just a few clicks.

ArTube is the CAD-CAM software for programming the BLM Group’s tube lasers. It allows its operators to draw, edit and design individual parts or complex assemblies of tubes with any cross-section. Artube is the most complete CAD-CAM software, which makes it dynamic and adaptable to individual customer requirements.

ArtCut is the CAM software for programming the 3D laser cutting systems. It can be used to program new parts offline and start production quickly and easily. Its intuitive 3D graphics simplify the programming of three-dimensional parts of any type, automatically resolving any collisions and realistically simulating the cutting process.

PartViewer is a powerful tool for graphically simulating the production programs for the BLM Group’s Lasertube family of tube lasers. With it, both the times and the costs of production can be calculated very accurately.

ProTube is BLM Group’s MES (Manufacturing Execution System) – the unified interface for easy and transparent management of part programs for BLM GROUP’s main machines. With Protube, customers prepare their work orders in the office, efficiently plan their production, send work orders to connected production sites, and monitor work progress. Combined with AI strategies and integrated with ERP systems, Protube becomes the key to intelligent Industry 4.0 applications.

Always customer-oriented with individual solutions

BLM Group offers a wide range of different services that accompany customers throughout the entire life cycle of their machines. This ensures maximum efficiency and machine availability. These services include: Software contracts and remote technical support contracts to quickly resolve unexpected issues and assist with new production requirements. Augmented reality tools such as Active Eye are also used in remote support. They can be used to quickly communicate the necessary instructions to the machine operators.

With BLManalytics, the production data of BLM Group machines can be monitored in real time and trends in system usage can be identified. This information is used to identify where process optimization is possible in potentially critical areas. This in turn forms the basis for targeted and rapid strategic decisions that maximize process efficiency and reduce maintenance costs and downtime.

BLM Group’s maintenance programs allow customers to choose the maintenance schedules that best fit their production needs. In doing so, they can plan the maintenance work so that their production is not interrupted and the service life of their machines is extended with special maintenance work: Routine maintenance and/or complementary maintenance, troubleshooting and supply of spare parts.

Web:

www.blmgroup.com