When we integrate a high-performance tube bending machine into our production process, we expand our core competence and open up a wide range of optimization potential in the production of our machines. With this goal in mind, Meiko opted for an E-Turn 40 tube bending machine from BLM. The calculation worked out for the manufacturer of professional warewashing technology and its customers.

© BLM

“Since the commissioning of the E-Turn 40 in October 2020, we have been able to produce many of our parts significantly easier, faster and more cost-effectively. In addition, the quality of the workpieces produced with the all-electric tube bending machine is significantly higher,” states Eberhard Kopf, Production Manager in the Flushing Technology and Plant Assembly department at machine builder Meiko in Offenburg. The company now produces nearly 450 different workpieces with the E-Turn 40.

For example, in the production of the latest transport rinsing machines of the M-iQ family, assemblies are used whose design could be greatly simplified with the BLM Group’s bending machine for tubes up to 40 mm in diameter. “Today, we manufacture the steam coils of the heating technology from a single piece,” says Mike Wittmann, team leader for installations at Meiko, citing an example. In the past, this component consisted of several individual parts welded together. In other components, such as manifolds for heating components, pipe sections with lengths of just a few millimeters had to be welded in. It is obvious: the production of such workpieces was extremely time-consuming and cost-intensive.

Significantly shorter lead times

“The process optimizations made possible by the E-Turn 40 are enormous. Beyond the higher quality of the workpieces, we now have a flexibility in tube bending that we never knew before. Our tube bending center can supply our production with the required parts faster than ever before. The new bending machine makes an important contribution to shortening the production times of our machines,” says Jonas Huber, Head of Installation and Assembly at Meiko, emphasizing the importance of the productivity gain. “Especially for smaller machines, short delivery times are an important decision criterion for customers today.”

Meiko is one of the market leaders in large dishwashing machines and systems for, among others, the food service industry, hotels, hospitals, cruise ships and airport catering. These machines are individually manufactured and equipped.

© BLM

Tube bending became core competence

The E-Turn 40 replaced a hydraulic bending machine purchased second-hand by the company many years ago. The technical possibilities of this machine proved to be increasingly limited, which is why Meiko purchased many tube parts from external suppliers. “Requests to suppliers take too much time and fit less than ever into today’s world. That’s why we wanted to acquire our own expertise in tube bending – in particular to be able to manufacture more complex components and assemblies ourselves,” says Wittmann, looking back on 2018.

In view of the current tense situation in global supply chains, this aspect has taken on additional significance. “The tube bending machine from BLM has made us independent. For new bent parts, we can quickly go into production and have full control over their quality,” Wittmann sums up the advantages. From rinse arms, hood brackets and heating coils to feed and drain lines, washing systems and countless other components made of high-quality stainless steel, the company’s engineering and production departments work more closely together than ever before in the development of innovative solutions. Thus, the tube bending step with the E-Turn 40 at Meiko fits seamlessly into the company’s strategy of securing its technically innovative position in the long term with a high vertical range of manufacture.

Meiko Maschinenbau is a company of the Oskar and Rosel Meier Foundation. Their tasks include maintaining jobs at the Offenburg parent plant or reinvesting profits. “This allows us to invest in state-of-the-art technology that gives us long-term competitive advantages,” Kopf explains. “The E-Turn 40 has given our machine operators interesting new tasks that make their jobs much more attractive. Against the background of the shortage of skilled workers in the industry, this was also important to us.”

© BLM

Software as a key measure of productivity

BLM Group’s easy-to-use and integrated software played a key role in the company’s investment decision. “We wanted to have software that did not require any programming knowledge to operate. When working with the BLMelements software suite, all you need is a little imagination,” Wittmann attests to the intuitive usability of these solutions.

With the VGP3D programming software, employees can design new parts in a few simple steps. Realistic 3D representations allow them to simulate all the details of the workpieces and the production process in advance, and to adjust every position and movement. The E-Turn 40 will later bend the parts exactly like this. Meiko works almost exclusively with step files. The company can optionally generate or import these with VGP3D.

B-Tools in particular are also seen as a highlight at Meiko. This software module automatically compensates for the elongations and springbacks of the materials in the bending process. “If we enter 900 as the bending angle, the machine bends exactly at this angle. With the E-Turn, the first parts are good parts,” says Wittmann, explaining the advantage, which is reflected in both higher productivity and higher profitability of the process.

The company uses BLM Group’s Tool Designer to manufacture the bending tools. With this software solution, it can generate the drawings for the required tools online via the operating console of the bending machine. These are then created automatically and are available for download in the form of step or PDF files. This, too, is a previously unknown convenience.

© BLM

Tube bending on a new level

With the E-Turn 40, Meiko bends not only round tubes, but also square tubes, oval tubes and solid material. The ability to free-form bend tubes up to 40 mm in diameter with variable radii gives the company additional flexibility, while the right-hand and left-hand bending in the process gives it many options in the production of complex and long parts, among other things.

In all this, the highest bending and surface quality is just good enough for Meiko. The all-electric technology per se guarantees the highest precision in all automatic settings and in all movements. In addition, there is wrinkle-free bending with and without mandrel, torque control, and mandrel and micro-lubrication. In short, the E-Turn 40 allows Meiko to pull out all the stops when it comes to quality. Thanks to the precision and flexibility of the machine, the company can also saw its pipes to final dimensions from the outset. This means that the parts are ready after bending and do not need to be sawed again. Material waste is also minimized.

Despite its versatility, the E-Turn 40 is quick to set up. This is simply because their software makes practically all the settings automatically. This is also a decisive factor for repeat jobs, as the machine is guaranteed to work under the same conditions for them. In addition, Meiko can mount two times three tool sets on the machine. This also supports fast production changeovers, as only the collets need to be replaced rather than complete tool sets.

Guaranteed sustainability

The design optimizations made possible with the E-Turn 40 also benefit the sustainability of Meiko’s products and processes. “We offer our customers resource-saving machines. For example, our M-iQ transport machines are characterized by low energy, water and chemical consumption. This reduces operating costs enormously for our customers. The technical possibilities of the E-Turn 40 support us in achieving such improvements,” Wittmann states.

Meiko’s sales department calculates for customers the savings they can achieve with the latest technology. Says Huber, “For some customers, the new M-iQ machines, which are used in both the food and industrial sectors, pay for themselves within four years.”

© BLM

All options for Industry 4.0

Meiko’s E-Turn 40 is connected to the BLM Group’s Telelaser service via the Internet. This means that their experts can directly access the machine’s control system. “Especially during commissioning and the start-up phase, this was very helpful for us. Our challenges were always solved quickly,” Huber recalls. Short e-mails to the service department are sufficient. The company can rely on receiving a qualified response quickly.

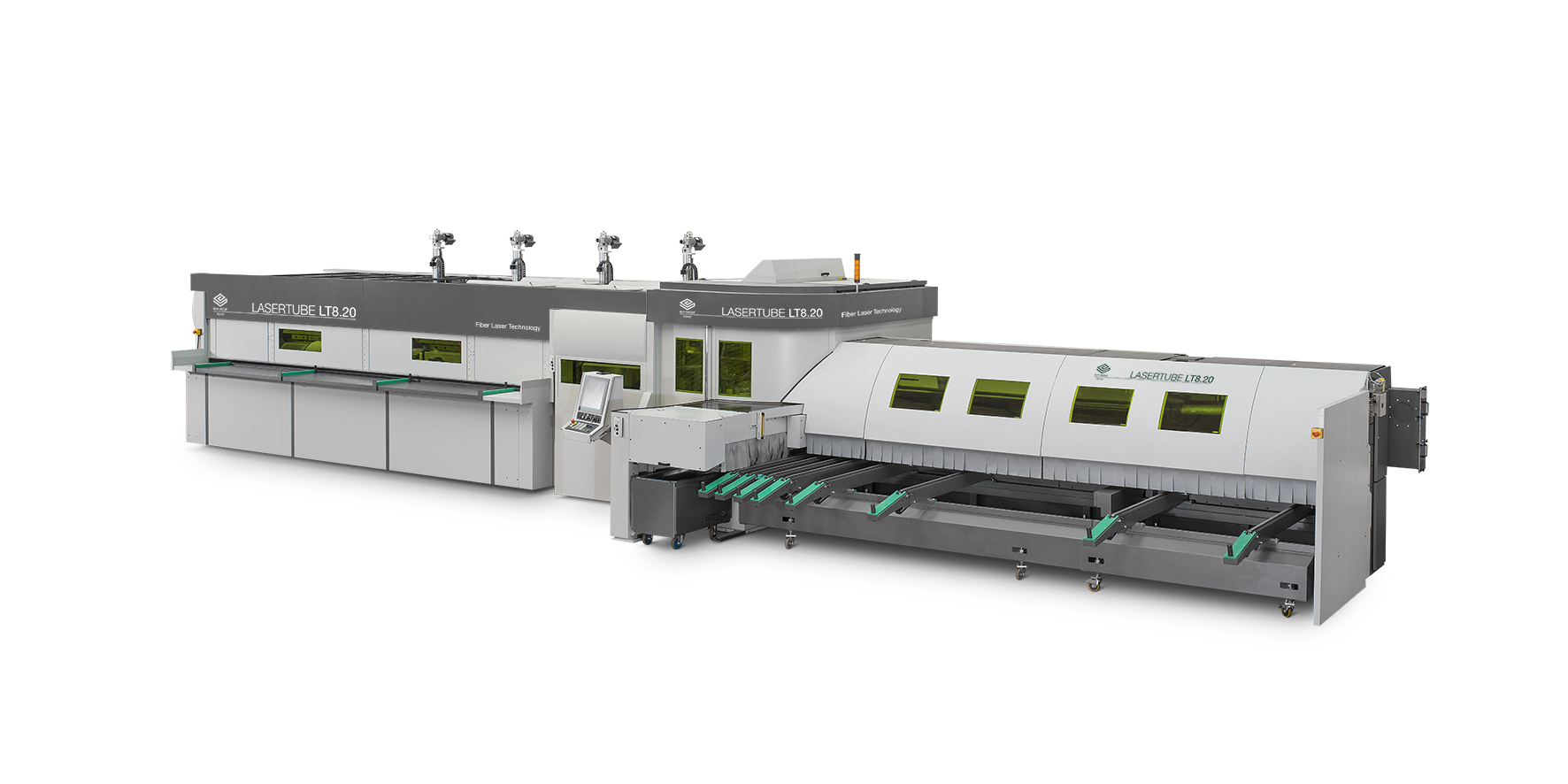

In the age of Industry 4.0, Meiko has also thought about the future in the course of this investment decision. Wittmann: “We took a look at the BLM Group’s plant in Cantù in Lombardy on site and, in discussions with the highly qualified experts, received confirmation that we are relying on the right partner here for the long term. This also applies in particular to the unique integration of this company’s machine technology. It offers us extraordinarily interesting options for the future for integrating end forming and tube laser cutting into our production process as well.” In this way, Meiko will be able to further expand its vertical range of manufacture in tube processing in cooperation with the BLM Group for the benefit of its customers in the future.

Web:

www.blmgroup.com