Hydrogen is becoming increasingly important as a clean energy source. For Scioflex Hydrogen GmbH, precise testing and certification of components and materials for hydrogen products is therefore essential. The testing laboratory relies on advanced testing machines from ZwickRoell.

In order to make reliable statements about material properties, tests under real conditions are essential. Hydrogen testing focuses on challenges such as high penetrability and hydrogen embrittlement. “With the ZwickRoell testing systems, we can perfectly characterize the material properties under application conditions. This opens up a completely new field of material characterization under the influence of hydrogen,” explains Dr. Bernd Schrittesser, Managing Director of Scioflex-Hydrogen-GmbH. This leads to a better understanding of materials, more reliable material selection and fracture mechanics as well as more precise service life predictions.

Hydrogen tests on metals and plastics

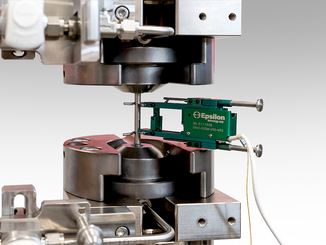

The young start-up based in Mattersburg, Austria, uses the Kappa 100 SS-CF creep testing machine and the servo-hydraulic ZwickRoell HA100 with 400 bar autoclave for a wide range of force- and strain-controlled creep fatigue tests, including under alternating load – including for determining hydrogen embrittlement and for hollow specimen testing. The company carries out material characterization in the field of hydrogen technologies for new and series products as well as special problems for its customers. In the area of metals, this includes hollow specimen tests, tensile tests and fatigue tests on thread specimens, as well as fracture mechanics tests on CT 1/2″ specimens. The tests on plastics include tensile tests, dynamic mechanical characterizations, fatigue tests and various fracture mechanics tests.

Wide range of frequencies and loads

Both machines can be used over a wide range of frequencies and loads and complement each other in terms of testing speed from “slow” (Kappa 100 SS-CF) to “fast” (HA100 servo-hydraulic testing machine). With both solutions, it is possible to work in the low strain rate range to enable SSRT (Slow Strain Rate Tests) investigations and to implement fracture mechanics or fatigue experiments up to a frequency of 20 Hz.

In addition, different load ranges up to 100 kN can be covered thanks to various force sensors and an optional temperature chamber can be implemented for measurements in the -40 °C to 100 °C range.

With ZwickRoell testing systems, Scioflex is coming closer to its declared goal of becoming an accredited testing laboratory for materials in the field of “hydrogen applications”.

About the ZwickRoell Group

Customers of the ZwickRoell Group benefit from over 160 years of experience in materials and component testing. ZwickRoell is a global leader in static testing and is experiencing significant growth in fatigue testing systems. Expressed in figures: ZwickRoell generated sales of € 288 million in the 2022 financial year. The Group has more than 1,650 employees and production sites in Germany (Ulm, Bickenbach), the UK (Stourbridge) and Austria (Fürstenfeld). ZwickRoell has further subsidiaries in France, Great Britain, Spain, the USA, Mexico, Brazil, Singapore and China, as well as worldwide representatives in 56 countries.

Web:

www.zwickroell.com