The new ZwickRoell battery testing laboratory in Ulm supports electromobility with mechanical tests to optimize battery components in terms of range, charging efficiency and temperature resistance. ZwickRoell thus promotes the performance, safety and acceptance of electric vehicles to a high degree.

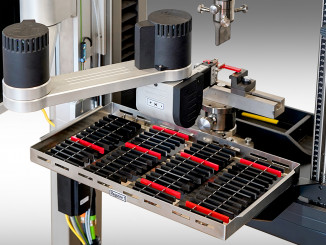

The battery testing laboratory, which opened on 28 February 2024, offers state-of-the-art testing technology for various mechanical battery tests for cell characterization. These are of interest both for research and development and for the production of batteries.

Comprehensive test procedures for battery cells and their components

ZwickRoell GmbH & Co. KG

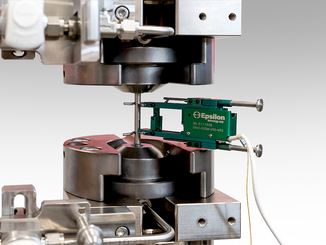

The laboratory offers a wide range of tests aimed at both individual cell components and complete battery cells. These include specialized tests such as film tensile tests and adhesion tests on electrodes, supplemented by temperature-controlled tests on entire cells. The testing experts also carry out tensile strength tests on separators, copper and aluminum foils and housing components.

The range also includes critical evaluations of weld seam and seal strength, shear strength of weld seams and connections, puncture resistance of separator foils and the adhesive strength of electrode coatings and insulation materials. Fatigue tests on welded joints and pressure resistance tests on batteries and their components are also part of the extensive test procedures.

In addition, electrical conductivity, compressibility and mechanical characteristics can be measured to support precise simulations and informed development decisions.

The tests serve to ensure the quality and performance of batteries in various areas of application. On request, ZwickRoell can also develop customer-specific testing concepts, advise on battery testing or carry out confidential tests in the laboratory. Two experienced application engineers advise customers on the selection of the right test methods and support them in carrying out the battery tests.

Opening as part of the E-Mobility Testing Symposium

The inauguration of the state-of-the-art battery testing laboratory took place in front of around 90 guests at the E-Mobility Testing Symposium at ZwickRoell. Representatives from research institutes and companies were present, including the Karlsruhe Institute of Technology (KIT), Cellforce Group GmbH, MBTS GmbH and Northvolt AB. Aleksander Koprivc, Business Development Manager Automotive-Electrification at ZwickRoell: “The laboratory is an important milestone for the entire industry and a source of inspiration for everyone working on the future of electromobility. It is a testament to our determination to drive innovative testing solutions and push the boundaries of what is possible. With this laboratory, we at ZwickRoell are taking our research and development activities to a new level and contributing to the transformation of the mobility landscape.”

About the ZwickRoell Group

ZwickRoell is a global leader in materials and component testing. Customers of the ZwickRoell Group benefit from over 160 years of experience in materials testing for various industries. In the 2022 financial year, the company generated sales of EUR 290 million. The ZwickRoell Group has production sites in Germany, Austria, Great Britain and China as well as branches and agencies in 56 other countries. ZwickRoell currently has more than 1,800 employees, 1,200 of whom work at the Ulm-Einsingen site.

Web:

www.zwickroell.com