Automated processes for cost reduction, traceability and sustainability are the focus at Blechexpo. Rea Elektronik supplies solutions for indispensable marking with ink, laser or labels, for code checking and wetting: systems, software and consumables.

Rea

One technology, several possibilities for sheet metal production – the Rea Jet HR 2.0 high-resolution inkjet printer and the Rea Jet DOD 2.0 large character inkjet printer are such multi-talented machines: They use a wide variety of inks to mark metal products of all kinds – and also apply LBI oil free lubricants precisely where they are needed without any mist or dripping. The stamping and bending machines remain clean, the finished parts do not have to be cleaned and can be processed immediately. Precise dosing and application with the digitally controlled nozzles of the Rea Jet HR is intended for smaller components, while the Rea Jet DOD system is used for large-area wetting.

Ink marking – “wet-on-wet” or with large letters

Thanks to its cartridge technology, the Rea Jet HR 2.0 is maintenance-free. It writes alphanumeric texts, logos as well as variable and serialized information in razor-sharp ink. The possible combination of four print heads enables marking up to a height of 50.8 millimetres. With two print heads, the Rea Jet HR 2.0 uses “wet-on-wet” technology to apply label content directly to smooth, transparent or metallic substrates. To do this, it first applies a white ink layer and then immediately writes black or colored ink onto it before the two dry together.

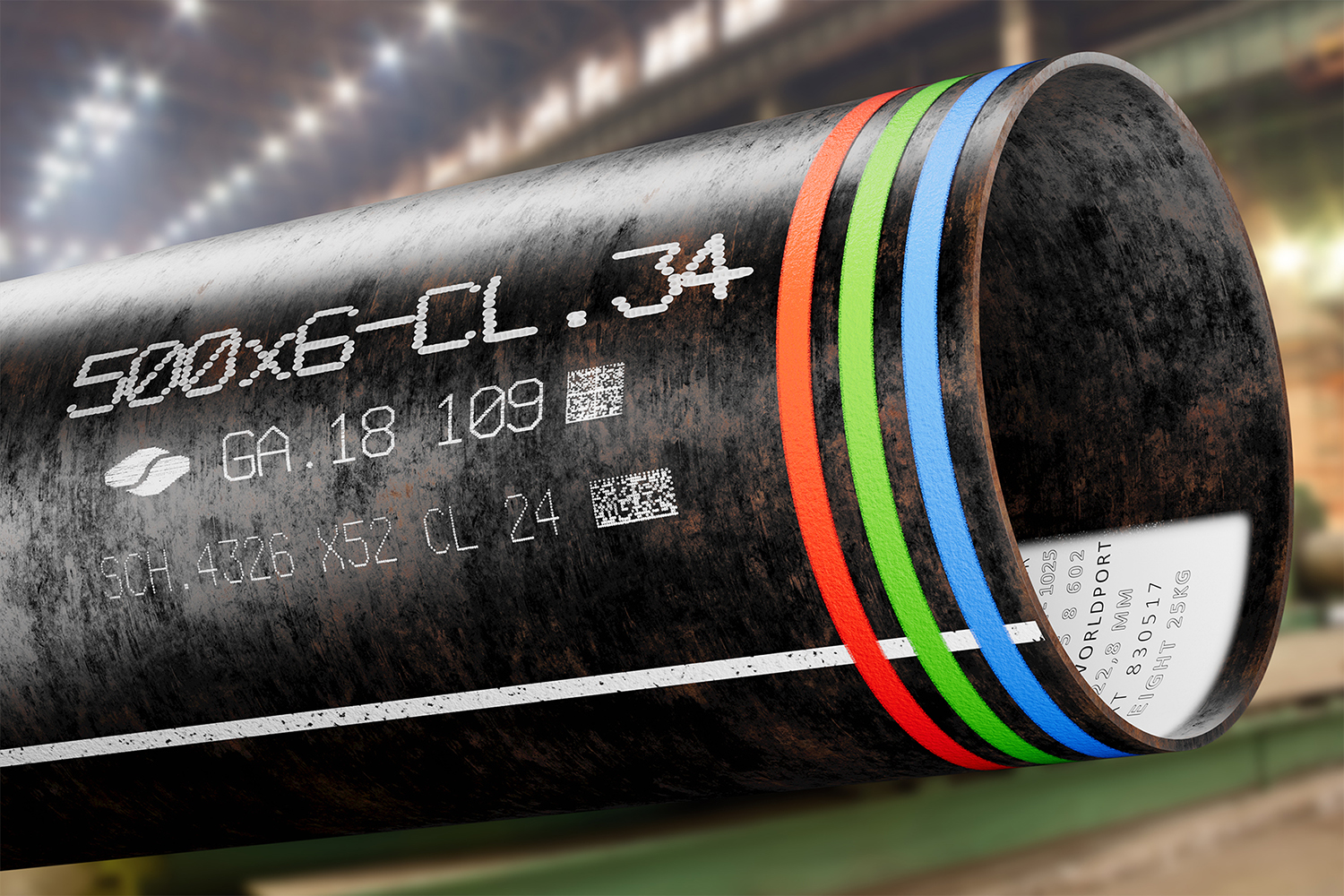

Using pigmented and quick-drying inks, the Rea Jet DOD 2.0 large character inkjet printer prints texts, data or logos from 5 to 140 mm high per print head on non-absorbent surfaces such as steel pipes or aluminum plates. Several print heads can be combined for larger markings. The fastest system in its class operates at speeds of more than 600 m/min and is also the most durable – with reliably excellent and high-contrast print results, even in the event of vibration and strong temperature fluctuations, in dusty and damp environments.

Rea

Laser marking – in the cabin or “on the fly”

The Rea Laser FL fiber lasers work reliably even on oily, corroded surfaces or surfaces at temperatures of more than 1,000 degrees Celsius and apply markings to harder metals or plastics. The Rea Laser FL200, FL300 and FL500 fiber laser models are characterized by simple integration and open automation interfaces based on XML. Using bundled light, they also write extremely small texts, logos and codes in high resolution. Their intensive and fast deep engraving can even replace conventional embossing systems for marking steel or aluminum. Alternatively, the marking is created by tempering, in which the heated material changes color.

If the Rea Laser FL is integrated into the individually configurable Rea laser marking station, its versatile concept enables laser processing at a stand-alone manual workstation through to fully automated, networked processing from batch size 1 to infinity. For the price of a series product, any parameters can be defined according to customer requirements – from the dimensions of the process chamber to the laser power, placement of the marking field and material feed and removal.

© Rea

Pinpoint accuracy with paint, varnish or process fluids

With pinpoint accuracy, Rea Jet ST marking technology solutions mark metallic surfaces where industrial processes require color markings – even at surface temperatures of up to 1,000 degrees Celsius. Even in areas that are difficult to access, they apply their information dot by dot with paint or lacquer. The Rea experts have also opened up a second field of application for marking technology: the Rea Jet ST systems apply protective coatings, primers or process fluids for pre- or post-treatment to metallic surfaces.

Markings and codes must be legible and also correct, for trouble-free automation and reliable traceability, compliance with international standard specifications and application-specific requirements based on ISO standardization. This is confirmed by the code verification systems in the Rea Verifier product line. The Rea VeriCube DPM with integrated dome illumination verifies directly marked codes on high-gloss, highly reflective surfaces. The universal, stationary inspection device delivers reliable results even with complex 3D shapes in order to optimize and maintain the print quality of the codes.

Background

Rea

Rea Jet, Rea Label and Rea Verifier are product line brands of Rea Elektronik GmbH, based in Mühltal near Frankfurt am Main. The partner company Rea Card develops and distributes cashless payment systems. Rea Elektronik was founded in 1982, is owner-managed and employs more than 400 people.

The Rea Jet product line develops and produces high-quality marking and coding systems for non-contact industrial labeling. The portfolio includes inkjet printers, laser and marking systems as well as inks and consumables. The practice-oriented products are suitable for all sectors and have proven themselves worldwide in a wide variety of industries.

The Rea Label product line develops and produces labeling technology solutions. The portfolio includes label dispensers, print dispensers, pallet labelers and special machine construction as well as thermal transfer printers and associated consumables such as labels and ribbons.

Hall 6, Stand 6301