Permanent and captive marking makes tubes and profiles unique, identifiable and traceable and wire ropes safe. At Tube 2024, Rea Elektronik will be showcasing its low-consumption, low-maintenance solutions and systems for non-contact industrial coding and marking.

Whether made from red-hot metal, freshly extruded plastic or poured concrete – pipes and profiles as well as wire products require a wide variety of markings: Machine-readable codes, which can also be serialized, provide reliable guidance through internal logistics and make products traceable for a lifetime – seals of approval, quality marks and manufacturer logos create reliability and trust. Rea Jet, the product line of the full-range supplier Rea Elektronik, offers all of this with its systems for contactless industrial marking and the special inks that are highly regarded in the industry.

At Tube 2024, the experts will provide an insight into the diversity of their range for marking and labeling tubes and profiles, as well as steel springs and wire ropes – which means that the applications were also of interest to visitors to the Wire 2024 trade fair, which was taking place at the same time.

Etching inks for permanent and high-resolution marking

Rea Elektronik GmbH

The Rea Jet HR 2.0 inkjet printers apply high-resolution alphanumeric text and logos as well as variable information such as date, time, counters, shift codes and database content to absorbent and non-absorbent surfaces. Depending on the size of the motif, up to four print heads can be combined to create markings 50.8 millimeters high. And maintenance-free too, thanks to cartridge technology.

The use of etching ink on metallic surfaces is recommended as a risk-free alternative to laser marking. The Rea Jet HR 2.0 uses a chemical process triggered by the ink to apply high-resolution motifs and serialized information to the metal in such a way that they remain permanently attached to it. Visitors to the trade fair will be able to see the effect of the application for themselves and see how metal workpieces can be permanently marked using this innovative technology.

Marking technology for high-resolution marking of the inside of the pipe

Rea Elektronik GmbH

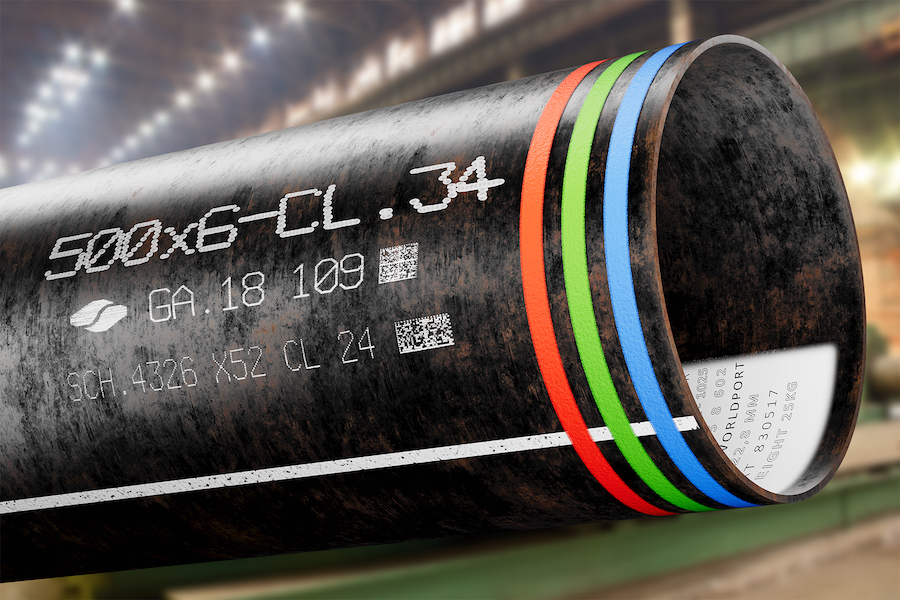

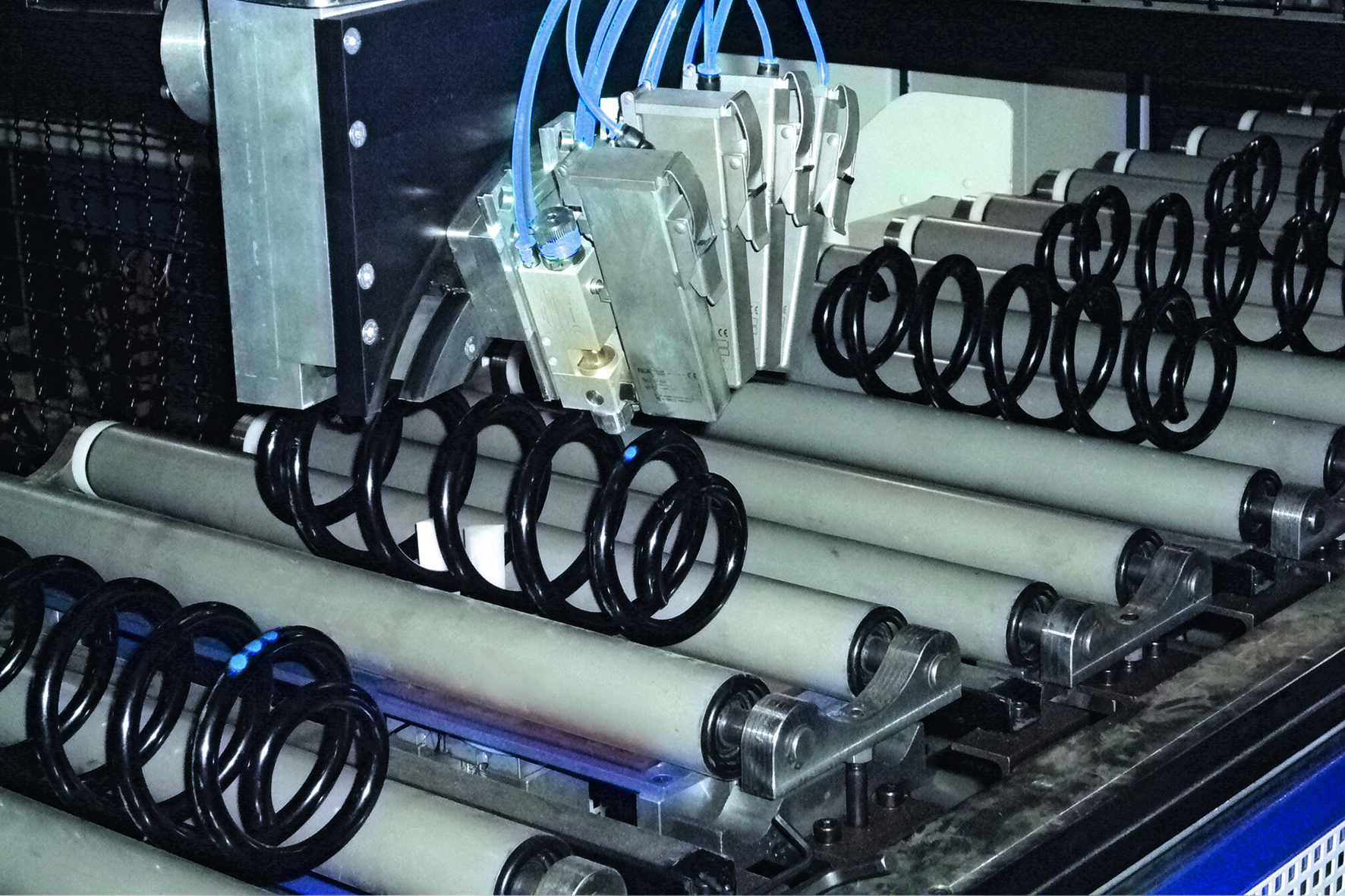

With a variety of colors and paints, the Rea Jet ST marking technology applies precise markings to metallic surfaces – whether dots to mark defects, lines to indicate weld seams or colored ring markings to differentiate between pipe types. Safety is provided by colored lines that make visible when wire ropes are twisted. Dots of different colors on steel springs indicate their damping strength.

With a block of several heads, the marking technology can write text up to 700 mm high – dot by dot. And nothing is too hot for her: her special paints hold securely on surfaces that are up to 1,000 degrees hot.

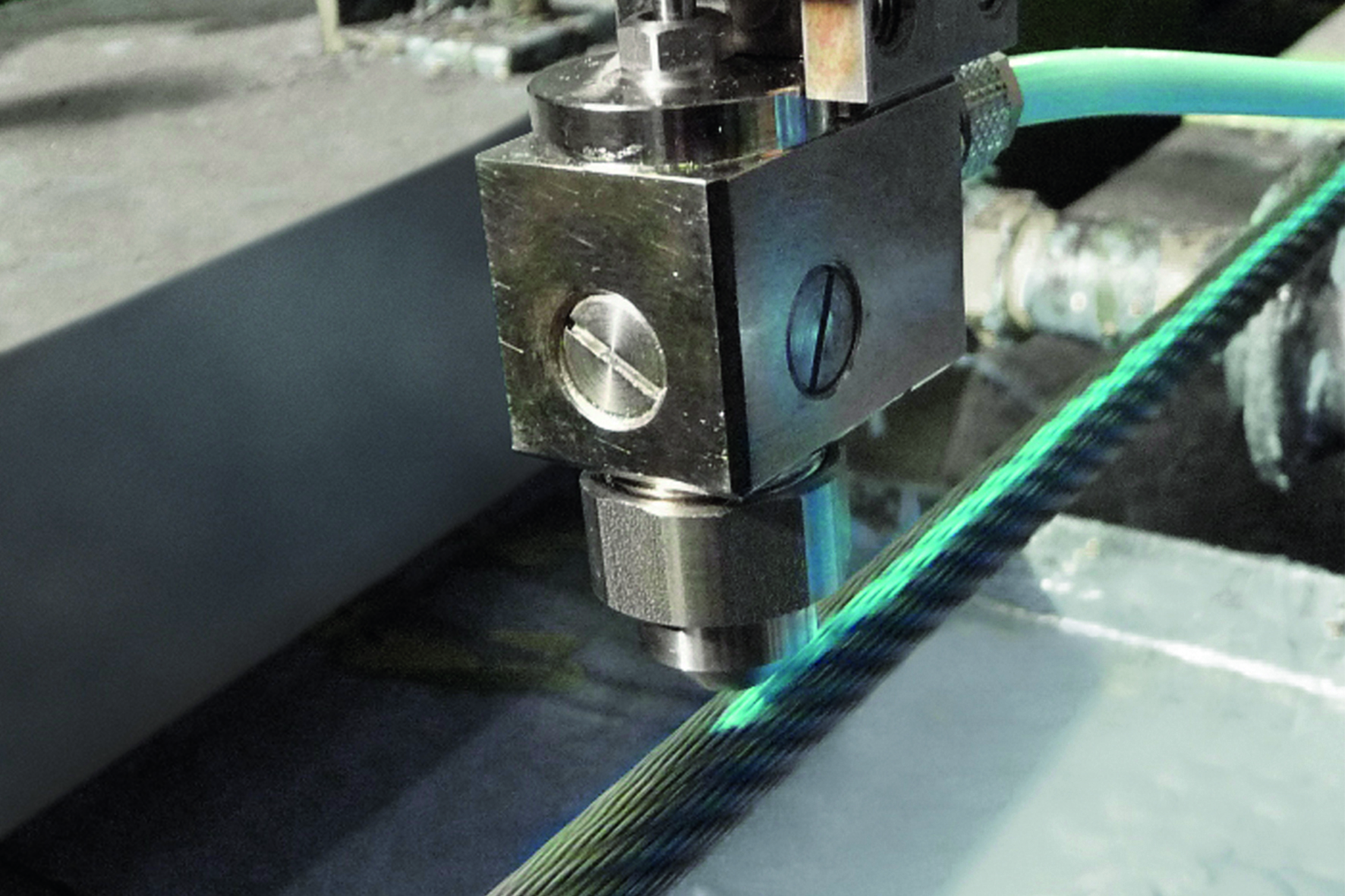

Rea Jet offers a special application of marking technology in combination with the Rea Jet CL CO2 laser for the high-resolution internal marking of pipes. In the first step, the marking gun creates a white mirror from laser-sensitive paint. In the second step, the Rea Jet CL lasers high-resolution information into the white color mirror. Texts and graphics of all kinds, including dynamic text fields, can be generated.

Large-print pipe labeling on the outside and inside

Rea Elektronik GmbH

The Rea Jet DOD 2.0 large character inkjet printer marks smooth, absorbent, oily and even scaled pipe surfaces with alphanumeric characters, logos and 2D matrix codes. Its fast-drying and pigmented special inks produce legible and durable markings at speeds of up to 600 meters per minute. In real time, it turns the data received from the production control computer into serialized plain text and 2D codes, making every marking unique and every pipe one of a kind. Even in the harshest environments, the fast and durable inkjet printer reliably writes large markings on the outside of the pipe. It prints data and logos in sizes from 5 to 140 mm with one print head – several print heads can be combined for print layouts of larger dimensions.

From an internal diameter of 200 mm, the Rea Jet DOD 2.0 also prints on the inside of the pipe. This is possible both with a moving writing head, mounted on a robot arm, and in a rotating tube.

One operating software for all

Rea Jet’s marking systems adapt to the individual needs of customers and can be flexibly integrated into production using state-of-the-art interfaces. As diverse as their applications are: All Rea-Jet systems can be operated with the software of the Rea Jet Titan platform. This makes their integration into existing systems even easier, saves time and money thanks to less training, simplified personnel deployment and fewer errors. Users can choose between the Rea-Jet universal controller with knobs and buttons for turning and pressing, and the Universal Touch Controller with a modern, tile-based interface on a display that can be operated by touch like a smartphone – even when wearing gloves.

Solutions for printing lubricants

The Rea-Jet systems are not only used for digital marking in metal forming, but also for the application of liquids. To this end, the cooperation partners Rea Elektronik and LBI oil free (www.lbi-oilfree.de) have successfully implemented the printing of oil-free lubricants with the Rea Jet HR Lube and Rea Jet DOD Lube systems.

For the Rea Jet HR Lube version, the oil-free lubricants from LBI oil free are filled in cartridges – for their digital dosing for preparing metals for stamping and forming applications. With thermal inkjet technology, precise lubricant images can be applied individually and with high contour definition – without mist or aerosol. This increases production and operational reliability, as the lubricant only goes where it is needed. The Rea Jet DOD large character inkjet printer is also available for lubricant applications. With different application widths and at printing speeds of up to 600 meters/minute, it also applies oil-free LBI lubricants without mist or aerosol.

Web:

www.rea-jet.com