REA Elektronik from southern Hesse is a globally active specialist that supports the packaging industry in meeting its diverse requirements for marking and code verification. Its solutions help them use resources more sustainably, meet market requirements, and comply with regulations. REA will be showing what these are – including some innovations – from September 27 to 29 at Fachpack 2022, Hall 1, Booth 1-228.

The packaging world is confronted with ever new expectations from manufacturers, retailers and consumers: Sustainability and single-sort disposal, digitalization and lean processes, global trade and e-commerce. REA Elektronik has the right solutions for this – and also looks ahead with its experts to anticipate developments in the industry.

Such as the 2D checkout code (for example, “GS1 Digital Link” or “GS1 Data Matrix”), which is expected to gradually replace the 1D EAN code from 2027. As a digital product label, it should also be able to provide the entire chain from production to logistics to retail with the necessary information and also enable direct communication with the end consumer. Manufacturers and retailers around the world are beginning to convert their systems to the new labeling – REA Elektronik is a GS1 Solution Partner and can support them with its technologies.

Not to forget: individual labeling regulations from a wide range of industries – such as serialization for safe pharmaceuticals or UDI (Unique Device Identification) for the traceability of medical devices. For the latter, the transitional period for product classes II a (medium risk) and II b (increased risk) expires in May 2023, at which time they must be marked with their individual identification code in machine-readable form.

All these tasks require high-quality marking along with reliable code verification. As a full-range supplier, REA Elektronik puts together complete solutions for the packaging industry’s most diverse requirements – with ink, laser and label, including code verification, in line with its motto “Print – Apply – Verify”. This is emblazoned across the new trade show booth at Fachpack 2022, the largest in the company’s history to date. On display: The entire range of marking and inspection systems for a wide variety of requirements, which can be integrated into existing production lines through interfaces and are thus fully Industry 4.0-capable.

Since Fachpack 2022 runs parallel to Powtech 2022, the bulk materials industry will also benefit, as the REA Jet HR inkjet printer and the REA Jet DOD 2.0 large character inkjet printer in particular are ideally suited for bag marking. The uniform REA Jet Titan operating platform for all REA Jet marking technologies also simplifies handling, training and personnel deployment for frequently changing marking tasks.

© REA Electronics

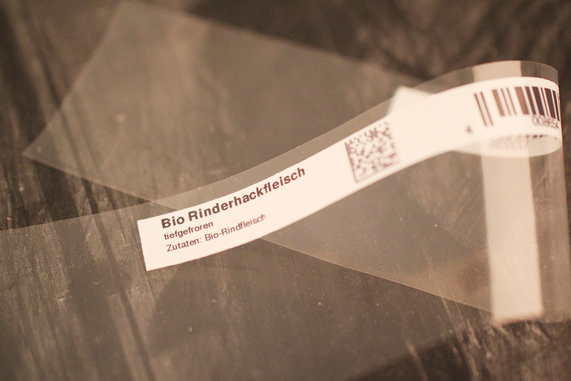

“Wet in wet” foil printing for sorted disposal

The REA Jet HR inkjet printer writes label content inline and “wet-on-wet” directly onto films or smooth surfaces – without any adhesive labels, the new technology applies codes and clear text to transparent and even dark substrates. To do this, the inkjet printer, which is equipped with a dual print head, first creates a white ink mirror. He immediately writes on this with black ink – optionally also in color – before both dry together.

Whether 1D, 2D codes or lines of text, the technology marks them with strong contrast, ensuring high quality and first read rates. It also saves work steps, reduces process costs and, above all, promotes sustainability. This is because the elimination of labels together with their carrier film reduces the amount of waste in production – and packaging labeled in this way can be disposed of by type after use and recycled more effectively.

In addition, with the new “hot swap function”, the cartridges of the REA Jet HR can be changed during operation, which ensures uninterrupted product marking. Heatable print heads ensure unchanged high print quality even in cold production environments.

© REA Electronics

Mark outer packaging sustainably, flexibly and cost-effectively

Eliminating the need for labels in secondary packaging is made possible by direct printing with the new generation of REA Jet GK 2.0 high-resolution inkjet printers. Flexible and at the same time captive, they describe absorbent and porous surfaces such as cardboard, paper or wood. With both static and variable information, they print freely combinable texts, logos and graphics. Piezo technology ensures print results with razor-sharp edges at print heights of up to 100 mm with just one print head. Like all marking technologies in the REA Jet product line, these devices are also fully Industry 4.0-capable and can be easily integrated into production with their compact design.

Inline pressure control

REA Inline OCR, with its use of artificial intelligence for demanding image processing tasks, is the perfect complement for all REA Elektronik marking systems. The interaction between marking and camera systems in throughput at high processing speeds represents an essential component of quality assurance. Completely integrated into the production and packaging process, it ensures that only fully and correctly labeled goods are shipped.

The high-performance camera in the REA Inline OCR quickly and accurately recognizes the content of applied information such as texts and codes – regardless of whether they were applied with ink, laser or label. The system compares them with the target specifications. Acquisition and complete evaluation are completed in the shortest possible time, at only 70 milliseconds per character element.

© REA Electronics

Check codes flexibly

The new REA Verifier VeriMax Mobile is designed for mobile use in production, laboratory, incoming goods and quality assurance. The offline verifier comes with its own tablet PC and checks the quality of 1D and 2D codes according to international standards, GS1 and other specifications to ensure high first-time read rates.

Labels are used especially where non-contact marking technologies are not a sufficient solution. At Fachpack 2022, for example, REA Elektronik will be exhibiting various solutions and materials for industrial labeling from its REA Label product line, in particular the REA Label Pallet Labeler and the REA Label Servo Labeler. New in the range: the REA label 5-color label printer. The system is designed for consistent production of effective labels. At speeds of up to 9 meters per minute, it prints runs of all sizes – from a single label to several thousand. Like all printing systems in the REA Label product line, it obtains its data from the Loftware-NiceLabel software. According to REA, there are no limits to the creative possibilities – and REA provides the user with a wide range of label materials as a basis, from economical to high-quality, from transparent to black, including metallic gold and silver colors.

Web:

www.rea-jet.com