Many companies in the sheet metal processing industry are slowly reaching their limits when it comes to handling sheets safely and in a space-saving manner. Eurotech, the specialist for vacuum, lifting and transport technology provides the solution: Together with Storemaster, the professionals developed a flat vacuum handling device for heavy duty sheet metal storage.

When Dieter Paul, owner of Storemaster, started looking for a suitable lifting device, it quickly became clear: he needed a special solution for his “MasterTower” sheet metal warehouse. Because even in the uppermost storage bays, the sheet metal plates should be able to be stored and removed quickly and safely, without a ladder and only by one person. In addition, the new lifting device should be very flat to make the best use of the space.

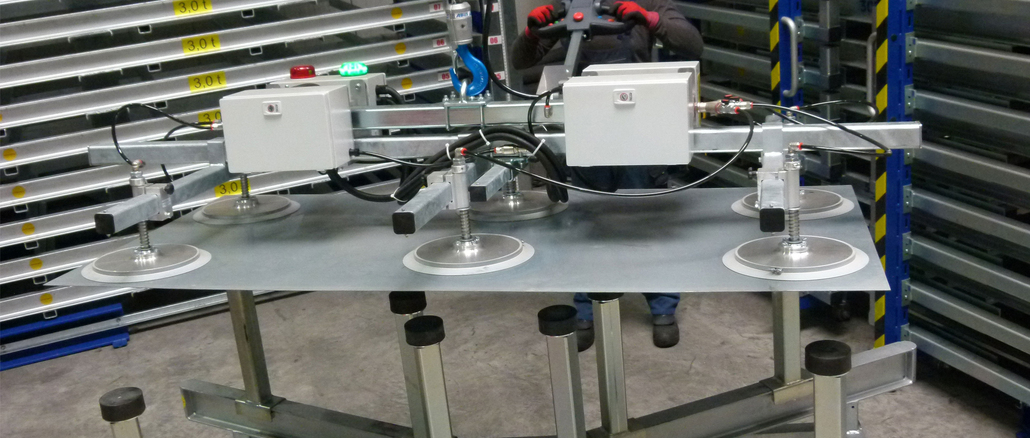

Paul found what he was looking for at Eurotech. The professionals from the Swabian Alb were able to help with a lifting device from the eT-Hover product family. The eT-Hover-panel was modified according to the wishes and requirements in a very short time. The new, flat version is just 350 mm high.

All functions of the device are controlled via an ergonomic operating handle; a thumb paddle triggers the up and down movement and suction and aeration can be activated at the touch of a button. The telescopic guide arm, which can be electrically bent in 22.5° increments, is also brought into an ergonomically optimal operating position via the operating handle without any special effort.

© Eurotech

In this way, the worker can always reach the bottom and top drawer from a comfortable standing position without bending or stretching. A centre of gravity compensation is also part of the basic equipment in this context.

The possibility of controlling integrated crane systems from the same operating handle, as well as the option of a mains-independent battery version, are evidence of a special innovation potential.

The revolving spiral cable has a double function, it serves to supply energy and control the chain hoist. The chain guide inside the spiral cable is designed to prevent the chain and cable from becoming entangled.

At the explicit request of the customer, a jogging function was installed. This device is used for double sheet separation in order to separate oiled or adhered sheets from each other quickly and easily. This prevents the risk of accidents in the event of uncontrolled double sheet removal.

The vacuum is generated by a vacuum pump with attached non-return valve, vacuum reservoir and two solenoid valves. These control the suction and ventilation. A blow-off device is installed for quick release of the load. All suction cups can be moved on the crossbars and can be shut off individually via a ball valve. The crossbars are also adjustable. In this way, the lifting device can be adapted to the corresponding panel sizes.

The eT-Hover-panel lifts small, medium and large sized sheets up to 4 x 2 meters and a weight of up to 750 kg. Special suction pads adapt to even problematic surface structures with a secure grip.

The lifting device is built according to DIN EN 13155. To prevent incorrect operation and hazards, it has several safety and warning devices: A built-in vacuum gauge with red/green range, a red and green signal lamp, an acoustic signal generator and a two-hand control for venting. The function of the electronic warning device is guaranteed even in the event of a power failure.

Climate protection thanks to KfW 55 standard

© Eurotech

Eurotech Vertriebs GmbH moved into its new business premises in Rosenfeld in May, in which the company invested 3.65 million euros. The state of Baden-Württemberg supported the project with 400,000 euros from the ELR and EFRE development programmes.

Construction work on the new company building in Rosenfeld’s Dornbrunnen industrial estate began with the official groundbreaking ceremony on 4 May 2020. Twelve months later, the production and storage areas (2,245 m²) as well as a two-storey administration building (740 m²) at Maybachstraße 7 have been completed. In the meantime, the approximately 40 employees of the specialist for vacuum technology have also moved into their modern premises on the 7,740 m² site.

“With this investment, Eurotech is taking another important step towards a successful future,” underlines Thomas Schulz, Managing Director of the medium-sized company. “The spatial realignment became necessary in order to meet the increased demands of the industry and the high volume of orders.”

Eurotech is thus returning to its roots in Rosenfeld, where the company was founded by Peter Bunnenberg in 1996. Since 2001, the specialist for vacuum, lifting and transport technology had its headquarters in nearby Geislingen. Another production hall had to be rented for years in Balingen.

The new building now not only offers significantly more space, with good connections to the A 81 motorway, it also stands out above all for its resource and energy efficiency: Built to the KfW 55 standard, the building requires only 55 % of the energy of a comparable reference building in accordance with the German Energy Saving Ordinance (EnEV).

The elimination of transport journeys between Geislingen and Balingen and the streamlined work processes will also lead to an increase in efficiency of around 20 percent. In particular, however, the new company headquarters creates the prerequisites for healthy, sustainable growth of the Swabian company.

Eurotech received support for the new building from the state of Baden-Württemberg. The funding line “Spitzen auf dem Land! Technology Leaders for Baden-Württemberg” funding line from the Rural Development Programme supports, among other things, the development and economic use of new products and services.

Web:

www.etvac.de