Sheet Metal Coils

A stroke of luck at the right time

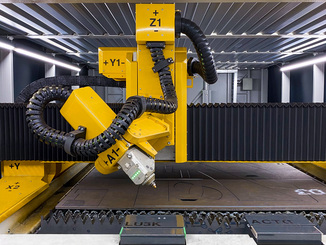

Metal construction, welded assemblies, machining of castings: Metallbau Ganzmann, a company based in Baden-Württemberg, Germany, is flexibly positioned. In 2021, the family business took advantage of MicroStep’s anniversary offer and […]