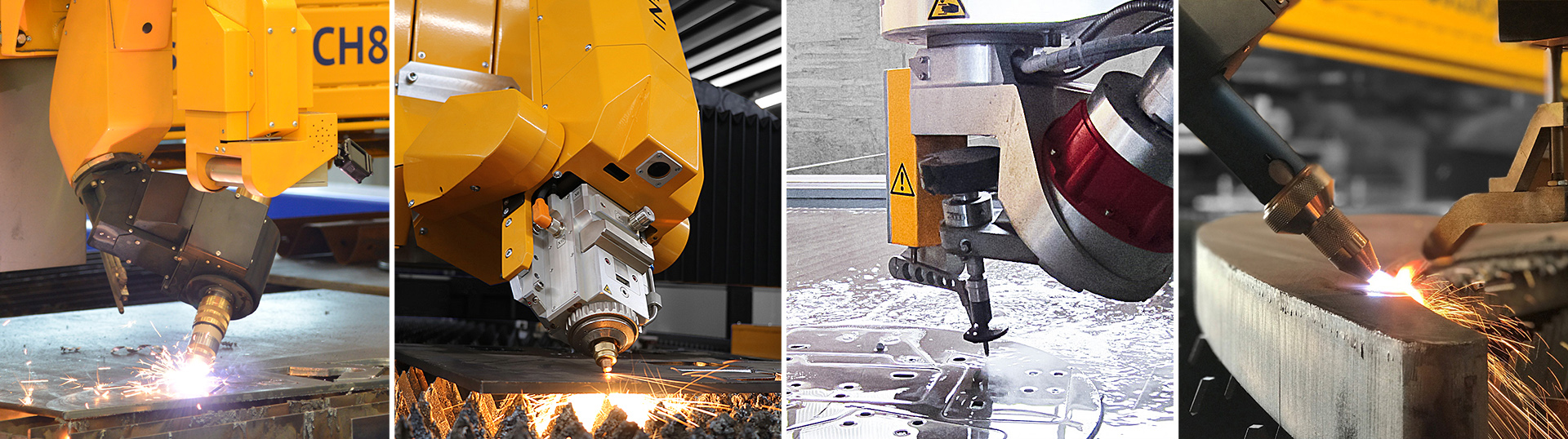

Metal construction, welded assemblies, machining of castings: Metallbau Ganzmann, a company based in Baden-Württemberg, Germany, is flexibly positioned. In 2021, the family business took advantage of MicroStep’s anniversary offer and invested in the PL Compact 2D package-priced plasma cutting system. “The machine is a stroke of luck,” says Managing Director Michael Ganzmann.

© MicroStep Europe

In the middle of the climatic health resort Häusern, only a few kilometers from Schluchsee in the Black Forest, Metallbau Ganzmann GmbH is at home. Friedrich Ganzmann started here in 1984 with a forge and locksmith’s shop, and this is where the steadily growing company still operates today. It supplies customers preferably in closer surroundings and offers the rich portfolio of metal construction, manufactures welded assemblies with mechanical processing, machines castings on large CNC milling machines, produces serial parts for industry and more. One customer is the Swiss snowplow manufacturer Aebi Schmitt. About 15 employees work with a lot of passion and experience on about 1600 sqm production area.

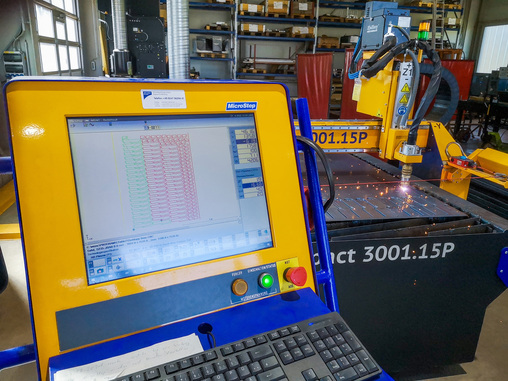

Since September 2021, a plasma cutting system of the PL Compact series from MicroStep has been a valuable production helper here. It is the first CNC cutting solution in the company, previously all necessary cutting parts were purchased. An investment at exactly the right time. “The machine is a stroke of luck. Our supplier was unable to deliver for weeks this winter. So we were able to cut 70 percent of our requirements ourselves. That helped us through the Corona winter,” explains Michal Ganzmann, Managing Director and son of the company’s founder Friedrich Ganzmann.

Idea met with skepticism by the father: “If, then we buy a quality product.”

In the middle of the year, the father had the idea to purchase an in-house cutting system. Son Michael was skeptical at first, but after a short in-sight he was also in favor; but only under the premise: “If, then we buy a quality product”. No sooner said than done. After a quick search, a demonstration appointment was made with a vendor. And here chance led to today’s solution. Just at that moment, the company’s long-time welding dealer, Grohmüller GmbH, came to visit. They recommended MicroStep without reservation and reported on their highly satisfied customers. “So we called MicroStep on Monday, had a demonstration the same week, and bought on Friday,” Michal Ganzmann looks back.

© MicroStep Europe

Decided quickly, benefited immediately

A quick and successful decision, even if the company had to gain a little experience with the first in-house fine plasma cutting system after commissioning. “We cut from 3 to 30 mm. Even at 30 mm, the quality is very good. We didn’t think we’d get such a great result there,” says the 37-year-old tool mechanic. In use, the PL Compact plasma cutting system is on average only a few hours a day, but still worthwhile at any time. Metallbau Ganzmann can now cut 70 percent of its own requirements itself; for the remaining parts, the necessary tolerances require the use of a laser cutting system. Here, the company continues to rely on external suppliers. “We are very satisfied with the PL Compact. We would buy it again and can only recommend it to everyone.”

Compact 2D plasma cutting system with a work surface of 3,000 x 1,500 mm

The PL Compact is suitable for entry-level CNC plasma cutting and the processing of 2D cutting tasks. The series impresses with a compact and space-saving design as well as an “excellent price-performance ratio” according to Microstep. Metallbau Ganzmann opted for a version with a working area of 3,000 x 1,500 mm. The company took advantage of MicroStep’s anniversary offer and invested in the PL Compact at a complete price with cutting system including Kjellberg plasma power source Q 1500, Teka extraction system AirCube as well as software, installation, commissioning and training. CAD software from ProFirst was also integrated on the recommendation of MicroStep. With it, cuttable CAD drawings in DXF format can be created as well as existing drawings can be corrected, edited and individual extracts can be exported. “This is very important for us. We work with many CAD drawings from outside and can now modify them perfectly for us. That makes it much easier for us,” says Michael Ganzmann.

Web:

www.microstep.com