With a subsidized StM waterjet system, resourceful metalworker Uwe Seck succeeds in making the leap from local niche supplier to regional just-in-time thunderbolt for industry.

Since 1998, Uwe Seck (55) has been running his metal construction company in Bad Camberg, Hesse, together with his son, his wife and two employees. His professional passion lies in “making things happen”, his focus is on custom-made products such as company signs, garden objects and individualized gifts for private customers as well as EN-1090-2 certified steel part series for small businesses in the region.

© Seck

Uwe Seck quickly established himself as a creative specialist for custom metal products. Most lucrative are his commercial customers, for whose orders he buys laser-cut parts from a contract manufacturer 35 km away. It quickly becomes cutting parts worth €45,000 a year, for which he has to wait longer and longer. The entrepreneur does not like that. He wants to become self-sufficient in manufacturing and starts looking for cheaper alternatives to laser cutting.

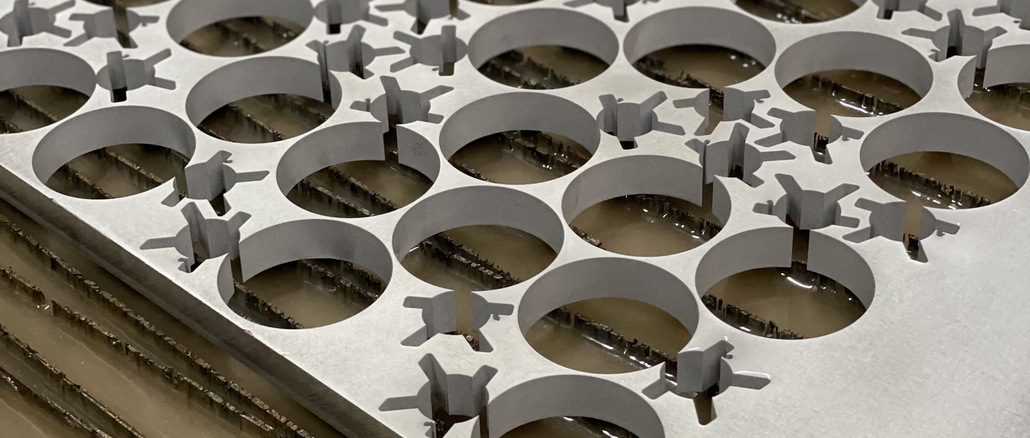

“Everything from a single source” is the new goal. In the end, it is son Tim, himself a budding toolmaker, who turns him on to waterjet technology. He becomes aware of StM at trade shows and in the technical literature and acquires a 19-year-old StM MasterCut gantry system with 3×2-meter cutting table for 50,000 euros in the fall of 2019 through the StM location in Schweinfurt – including a one-year warranty plus support. This not only makes Uwe Seck independent in one fell swoop, but also opens up completely new areas of business. Soon he is cutting with abrasive or pure water as needed, and in addition to cutting parts made of metal, he also produces workpieces made of ceramics, wood, rubber, granite, porcelain stoneware, copper foam, plastic and various special materials.

Problem

After 18 months and 700 hours of operation, father and son are convinced: The growth possibilities exceed the current capacities of the company. With this realization comes the decision to realign the business and specialize in more lucrative manufacturing for commercial needs. Out of curiosity, Seck inquires at StM in Schweinfurt about a more powerful plant. There, they recommend a PremiumCut system including a cutting head with angular error compensation, servo-driven high-pressure pump and OneClean cutting water treatment. An all-round energy-efficient precision system that would open up new dimensions for Uwe Seck in terms of quality, output and cost-effectiveness. The only problem: The acquisition costs of 220,000 euros make the 55-year-old doubt whether this investment will still pay off.

Solution

© Seck

Confronted with these concerns, StM draws his attention to EU funding for more energy-efficient manufacturing technologies. Even more, the waterjet pioneer offers to support the entrepreneur in the application process and to take the old plant on commission. The family strikes enthusiastically. Soon after, Uwe Seck is awarded the EU grant and with it a 92,000 euro subsidy for the purchase of the StM PremiumCut in the configuration of his choice.

His old plant, which continues to run perfectly, will be sold in parallel to a company from the region at a cost price of 50,000 euros. Seck himself only has to bear the maintenance costs in the end. He hands over the private customer business to his two employees, who also manufacture their orders as subcontractors with the new system. He and his son set about expanding the B2B business – supported by wife Annette Seck, who successfully boosts new business via Instagram.

Result

The new plant will be commissioned in early 2021 and will be coupled with the photovoltaic system on the roof, which has already provided 10,000 KW of electricity in 2020, covering 50 percent of the total demand. The four of them get trained at the Austrian StM test center and, after a few startup problems, master the system thanks to son Tim and, later, support from StM Austria. So well, in fact, that the son can continue his education and the father “runs the store” in personal union.

Now it cuts workpieces up to 2×3 m in size and up to 250 mm thick ten percent faster than before, and also more precisely with perfectly square edges. New business is picking up, so after ten months he has used the plant 650 hours, increasing utilization by 80 percent.

“It was a struggle at first, but now I’m thrilled,” says Seck. “The new system cuts faster and more accurately. It stops automatically when a cutting job is finished. In addition, pumping out the cutting water with OneClean is much easier and more economical than before with air. But the best thing is: Finally, we also have a super-competent StM employee in the form of the service technician from StM, who set up the system optimally for us and is always approachable and has a solution for everything.”

The plant is self-financing from day one. No job is exotic enough not to accept. Even though Seck mainly works with steel, he continues to cut custom products such as wooden floors for fire trucks out of passion. “Never has ‘can’t be done’ applied to me more than it does now,” Seck notes with satisfaction. “That’s almost more important to me than great financial success.” His conclusion: In the end, he has tapped into a growing market niche with his cross-material just-in-time full service for companies in the region, which would not be profitable with other production methods. Optimal conditions so that his son and successor can also fully develop professionally.

Web:

www.stm-waterjet.com