Whether thick or thin sheets – Arku Maschinenbau has something new to offer. The EdgeBreaker 3000 Next and the EdgeBreaker 6000 in particular are expected to attract the attention of experts.

The new EdgeBreaker 3000 Next deburring machine for punched and laser parts will be the focus of the trade fair presentation.

Thanks to a new drive solution, users save up to 40 percent energy.

Visitors have a direct view of the machining process through a large glass front, which significantly improves process control.

Additional functions increase productivity, which is already 50 percent higher.

AI-supported machine setting for the best machining results

AI-supported machine setting for the best machining results

How machine operators achieve magical powers can now be seen on almost all Arku straightening and deburring machines. On the Arku, the EdgeBreaker 6000 deburring machine and the FlatMaster 55 part leveling machine are equipped with the Wizard software.

This is an intelligent control system that adjusts the machines to achieve the best results. Users no longer have to try out which setting is correct when straightening or deburring sheet metal. The operator only enters the already known workpiece data into the control system (e.g. material, size of burrs, material thickness, desired edge rounding). The software then automatically selects the best machine settings for the respective machining task. The straightening or deburring machine then adjusts itself automatically. This is a great advantage when teaching the machines and avoids errors due to incorrect operation.

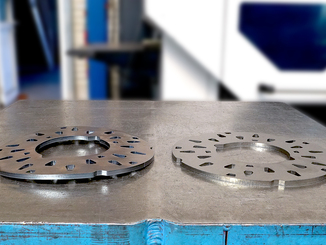

Visitors will see the EdgeBreaker 6000 deburring machine live in action.

It is suitable for deburring, edge rounding and surface finishing.

With rotating brushes, it achieves an even rounding of up to two millimetres in radius.

According to Arku, its flexibility makes it an all-rounder among deburring machines for a wide range of processing results, shapes and dimensions.

This makes it particularly popular with laser job stores.

© Arku

Coil laser systems increase material efficiency

Another highlight at the stand will be the topic of coil laser systems – a development in cooperation with Trumpf. It enables sheet metal processors to flexibly produce even medium batch sizes from coil. This produces much less waste when cutting parts compared to laser cutting from the standard PCB. By eliminating the format limits, sheet metal parts can be nested more efficiently.

This enables material savings of up to 30 percent for large parts.

Low stress and flat parts thanks to straightener

Arku also shows how important it is to straighten the sheet metal parts after cutting in order to reduce unevenness and residual stresses. The FlatMaster 55 straightening machine can be seen live on the exhibition stand.

It incorporates Arku’s know-how from 60 years of straightening machine production and contract straightening.

The Arku part straightening machines can bring sheets with a thickness of up to 60 millimeters into a flat state with the lowest possible residual stresses.

Web: www.arku.com Euroblech Hall 11, Stand A94