Optimized automation in sheet metal processing in the area of straightening and deburring were the focus of the InfoTage 2023 from Arku Maschinenbau.

The automation requirements for plants in the field of straightening and deburring are continuously increasing and Arku is successfully keeping up with this race. “Increasing throughput is what the plants are expected to achieve, despite increasingly complex processes and against the backdrop of a shortage of skilled workers. This is a problem that we have successfully addressed at Arku,” reports Dr. Jochen Kappler, Managing Director at Arku. One solution here is intuitive, simple operation. Furthermore, the company relies on “complete systems” to finish parts in one pass. “An important feature here is the communication capability of the machines, also with regard to Industry 4.0 and the possible integration into a higher-level control system,” adds Jochen Kappler. Other important aspects are the integrability of new plant components, plus energy efficiency and sustainability.

© Arku

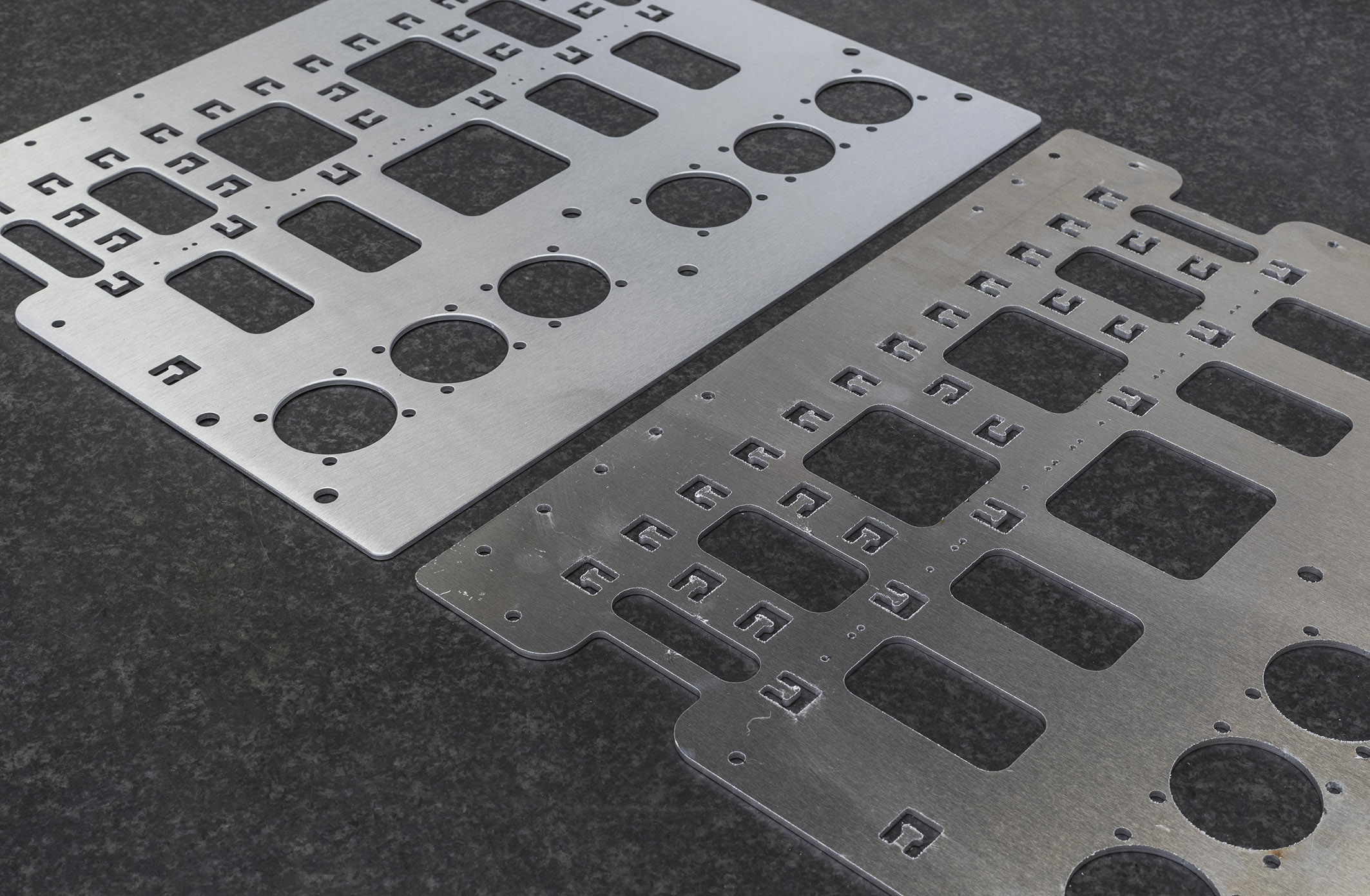

“At Arku, we are way ahead in these disciplines,” says a pleased Jochen Kappler, referring to the new EdgeBreaker 9000 Line machine combination. This system brings together the EdgeBreaker 4000 deburring machine with the EdgeBreaker 5000 slag hammer and performs complete processing of flame or plasma parts after cutting in just one pass. This eliminates the need to reload parts between deslagging and deburring. Since the two machines can be controlled centrally, only one operator is needed. For this purpose, both machines are equipped with Arku Connect, which enables linking with further aggregates or robots.

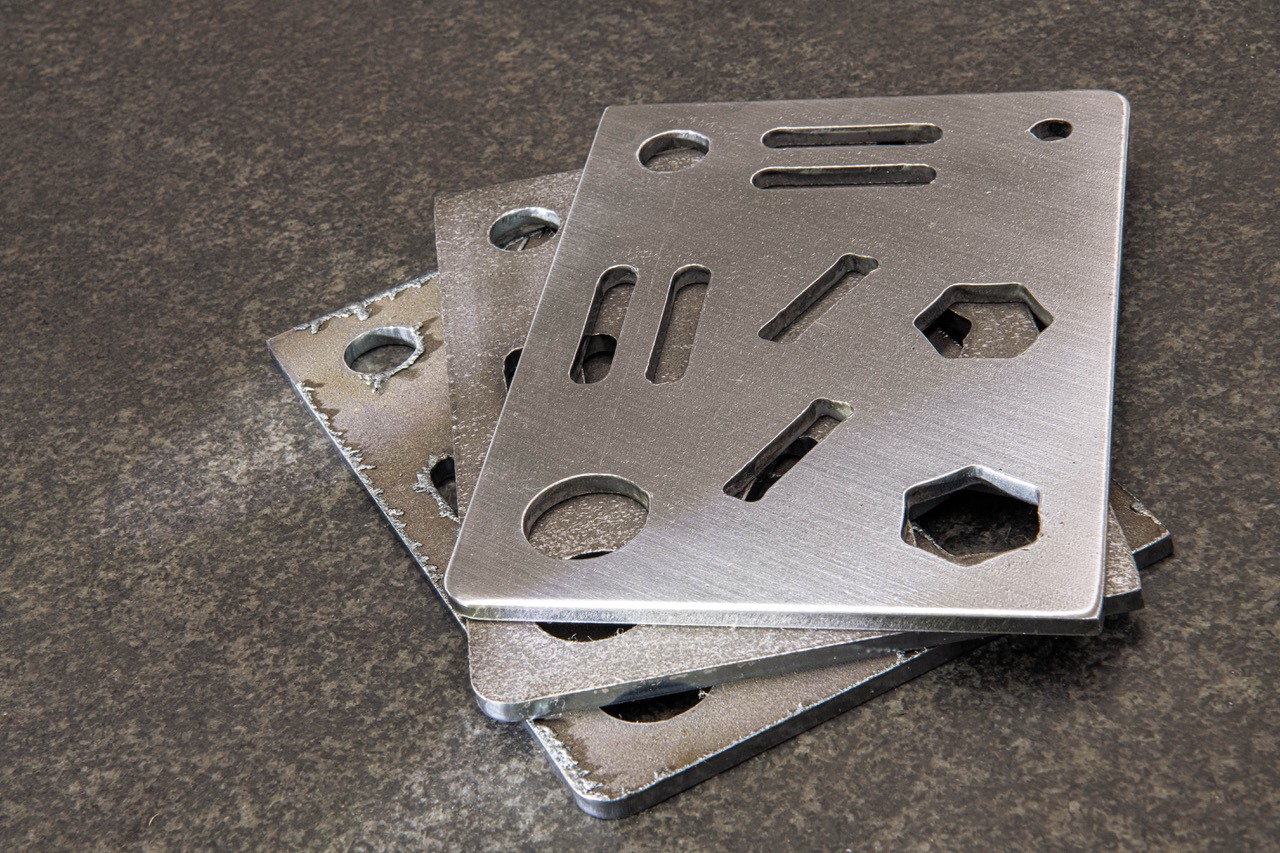

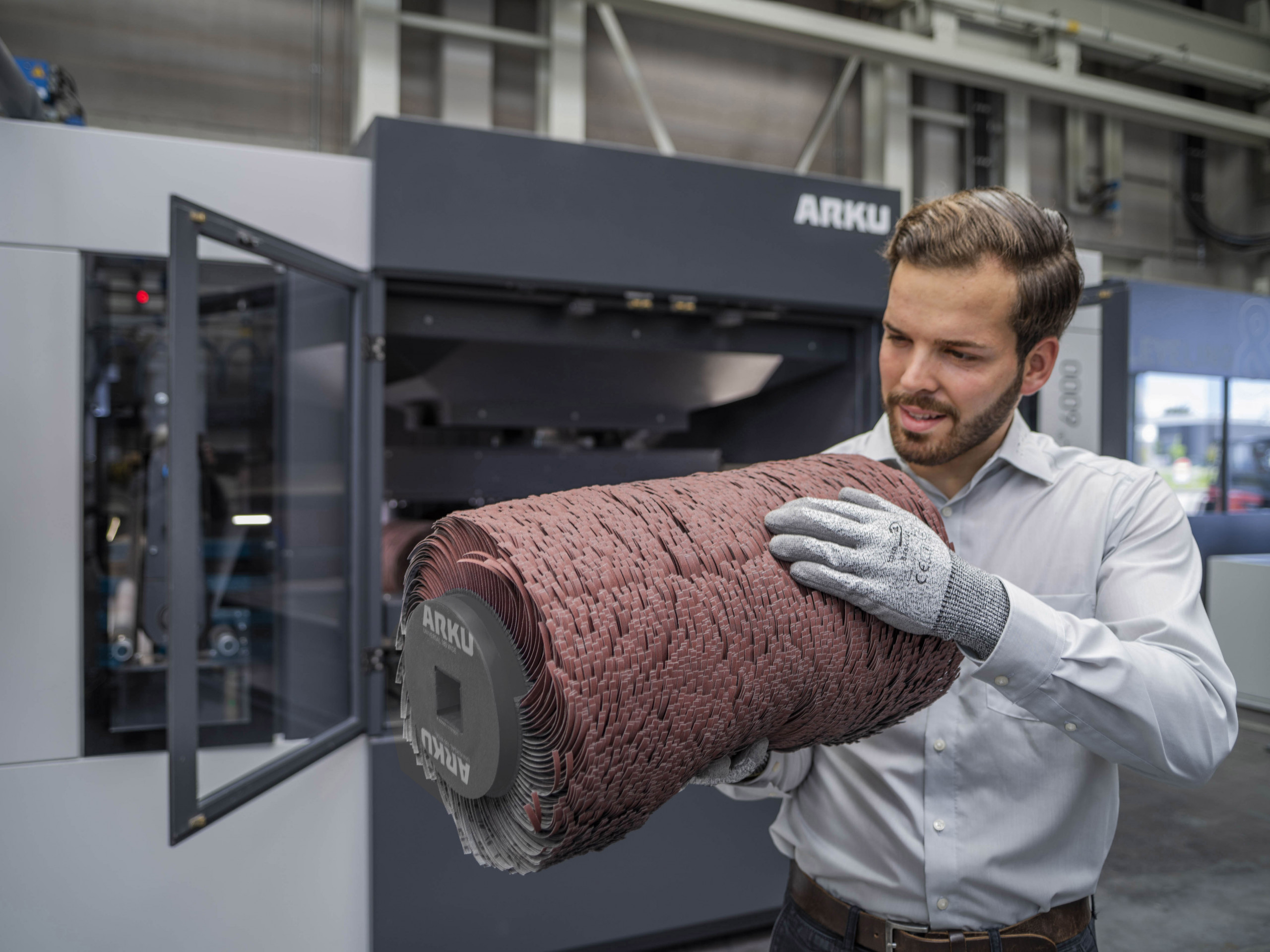

The new deburring machine for punched and laser parts, the EdgeBreaker 6000 also serves the upcoming trends. This particularly flexible system is especially suitable for laser job stores with a highly varying parts spectrum. The Wizard software also allows less experienced employees to work on the system. The wizard uses four tool settings to select the appropriate deburring tools in each case and calculates the optimum machining operations. This ensures maximum productivity and low wear of the deburring tools. Thanks to AI (artificial intelligence), it is easy to use. You describe the initial state of the parts and tell the machine the desired part result; the machine does the rest.

© Dr. Barbara Stumpp

Straightening processes more efficient with the robot

This year, Arku is focusing on the automation of straightening. Because a robot is ideally suited for the repeated loading and unloading of a straightening machine. Arku demonstrates this with the interaction of the FlatMaster 88 leveler, the FlatJack flatness control system and the EasyBot vision robot.

The straightening of coils is also important. Here, Arku has developed new coil laser systems together with Trumpf in order to be able to produce even medium batch sizes flexibly and without much waste. In addition, coil laser systems offer higher machine run times than systems that process sheet metal. Both reduce parts costs. Laser cutting systems fed with strip material reduce part cutting by up to 30 percent.

Arku has been dedicated to straightening sheet metal for over 50 years anyway. This is because sheets from the coil naturally have a constant defect: the coil curvature interferes with further processing. But there are other deviations, for example with narrower sheet metal strips, curvatures can occur transverse to the strip direction or torsions can occur.

Both coil defects and residual stresses in sheet metal can be corrected by straightening, turning a warped sheet into a flat workpiece that meets the required tolerances. Straightening machines straighten the plates with the help of rollers, eliminating both defects and stresses.

Straightening then has a positive effect on the subsequent machining processes: If the sheets contain as few residual stresses and defects as possible, bending or milling becomes more precise. Welded assemblies thus become more dimensionally stable and time-consuming reworking is eliminated.

For its straightening and deburring machines, Arku uses “camera-armed” robots that do not need to be taught. The operator only has to position a pallet with blanks. With the help of cameras, the robot can detect the stack height, position and orientation of the sheet metal parts. He selects the appropriate gripper and lifts the sheet metal part onto the machine. After straightening or deburring, he puts the parts back down.

© Dr. Barbara Stumpp

Investments for the future

“Our machines already have communication interfaces now. This means that customers can upgrade immediately or later to integrate the machines into their production processes in a plug-and-play manner. In this way, we will continue to enable our customers to use the latest system technology reliably and economically in the future,” confirms Jochen Kappler.

Furthermore, Arku has invested in a new production plant in Bühl, where customers can see for themselves the new flow assembly for deburring machines and the assembly of parts straightening machines.

Web:

www.arku.com