The special thing about the software from Lantek, the IT specialist for sheet metal production, is that it works independently of machines and can communicate with systems from any manufacturer and cutting technology via special interfaces.

The new Lantek “Machine Connectivity” technology now goes one step further towards Industry 4.0: the software can now integrate the machines into a comprehensive network, control them, record their data and display it clearly for the user.

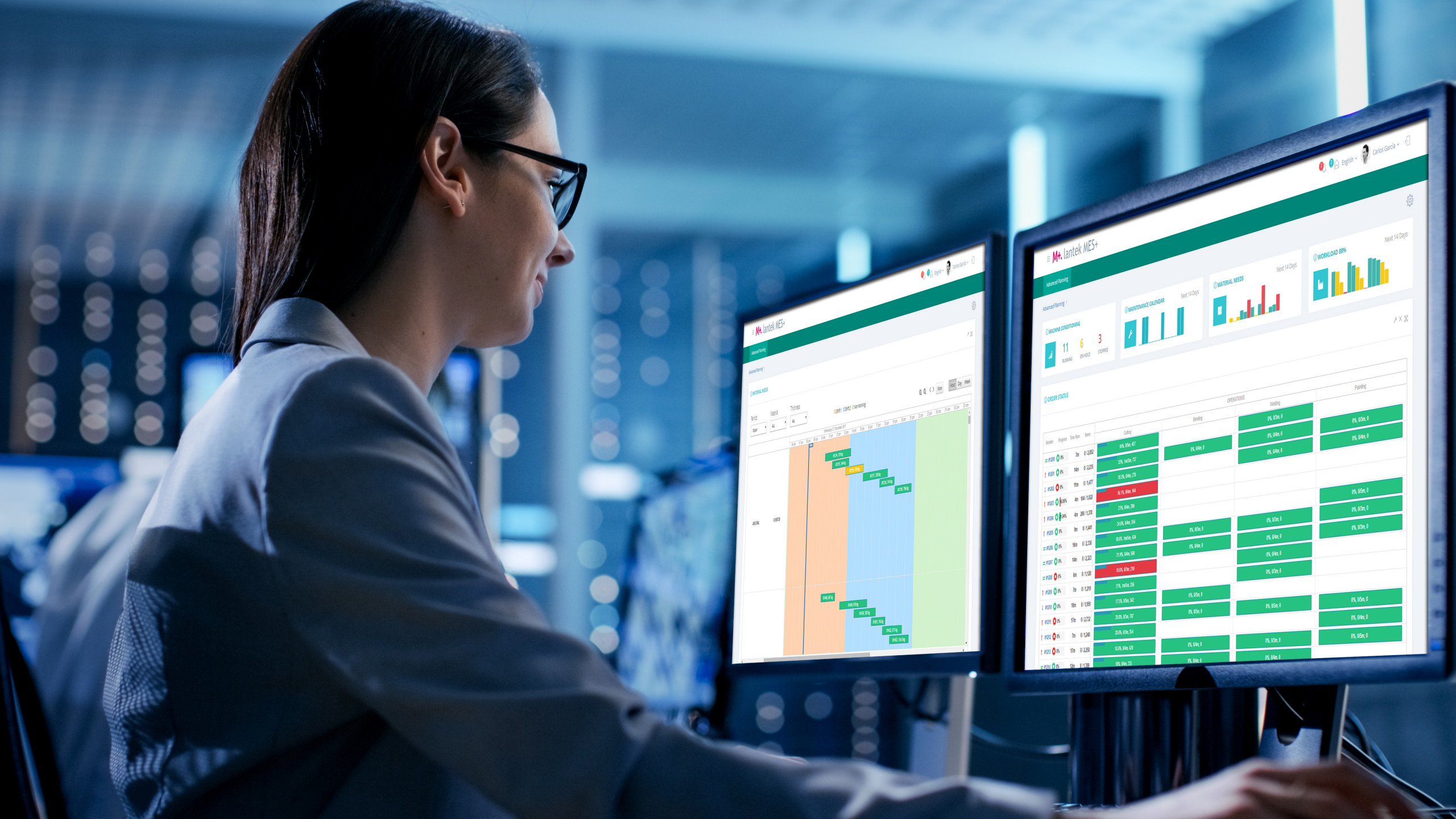

When there are machines from different manufacturers for sheet metal processing in a workshop, which also work with different technologies, it’s easy to lose track. Not so with the “Machine Connectivity” technology from Lantek. It understands all the machines, links them into a network and enables them to be controlled in a coordinated manner. The most important tools of Machine Connectivity are Lantek Live WOS and the cloud-based app software Control Panel. To understand what this means for sheet metal production, a quick look back helps: Originally, the nesting result of the Lantek Expert CAD-CAM software, which was sent to the machine as a CNC file, was printed out on paper so that the operating personnel had all the relevant information on the components and the plates intended for them. Once machining was complete, the new status was recorded in the system using Lantek MES Workshop Manager production management software. Then came Lantek MES WOS: installed on the computer or tablet at the machine, the software shows the operator which nesting plan assigned by the production manager is currently to be processed, including all the necessary information. After processing, the operator enters the new status, which is reported back to Lantek Manager via the software.

Machines communicate the production status themselves

With Machine Connectivity, Lantek is now taking automation one step further, as the Lantek MES Live WOS software can now take over the activity monitoring of all machines on the shop floor. The integration mechanism makes it possible for the machines to communicate their production status themselves. When Lantek MES Live WOS is activated, its “Play”, “Pause” and “Stop” buttons are deactivated because the software takes over the completion notification of the cutting jobs – including the feedback to the production management system (Lantek MES Manager) as soon as the job is completed. “Machine Connectivity is a signal converter that reads and interprets the control states of the machines and converts them into measurable information,” explains Christoph Lenhard, Head of the German Lantek office. “Ideally, the machine interface has the standardized OPC-UA format, i.e. it complies with the uniform Open Platform Communications standard, or we find another way for Live WOS to understand its signals.” The benefits of the Machine Connectivity concept become fully visible with the Lantek Control Panel app. The cloud-based application runs on the “Lantek 360” software platform. In real time and via the cloud, it receives the data from all machines involved in the cutting processes via Lantek Live WOS and displays it in clear representations on a desktop PC or mobile device, such as a tablet. “On the Control Panel interface, I can see the live status of all machines, which nesting plans are currently being produced, and I’m not just shown a long list of CNC codes,” explains Lenhard. “I can also jump to the tile of the next nesting plan and see which job the machine should work on next.”

For a comprehensive overview

The display shows a detailed visualization of all machine information in real time with the current status of all machines, their utilization and free capacities in the entire machine park. It also shows warnings or changes in the operating process so that the user can react quickly in an emergency, avoid errors and cost overruns – and can divert orders to other machines in the event of machine downtime. With the help of Machine Connectivity, Lantek MES Live WOS and Lantek Control Panel give managers a comprehensive overview of everything that is happening on the shop floor – wherever they are when they look at their mobile device. It enables them to effectively monitor and control cutting processes to optimize the use of available machine capacity and, last but not least, it facilitates and improves their decision-making based on valid real-time data.

Turbo for the production of 3D sheet metal parts and assemblies

With the new “Assembly to Nesting” (A2N) technology, IT expert Lantek is launching a tool onto the market that enables sheet metal production to complete in just a few minutes what previously took hours: reading in 3D drawings of individual parts and even complete assemblies with a large number of individual parts, processing them and calculating them for production.

In Germany, Lantek is presenting the innovation for the first time at Euroblech in Hanover.

Web:

www.lantek.com/de

Hall 11, Stand C08