Lantek has developed a new gating type for the Q 4500 plasma power source from Kjellberg Finsterwalde – available with other new functions in the 2023 software update, which the IT specialist is presenting at the Schweissen & Schneiden trade show.

© Kjellberg

According to the supplier, the high cutting qualities of the Q 4500 plasma power source when cutting mild steel, stainless steel and aluminum, even in larger material thicknesses of up to 120 millimeters, sets new standards in the industry. With a cutting current range up to 450A, it is the most powerful plasma power source in Kjellberg’s new Q series for precise plasma cutting in digitized productions, which also includes the Q 1500 and Q 3000 systems. High cutting speeds also reduce costs and increase efficiency. Via a browser-based interface developed by Kjellberg, process data and information from all plant components are available in real time on Internet-enabled devices, regardless of location.

Closing ranks with manufacturers of components and machines

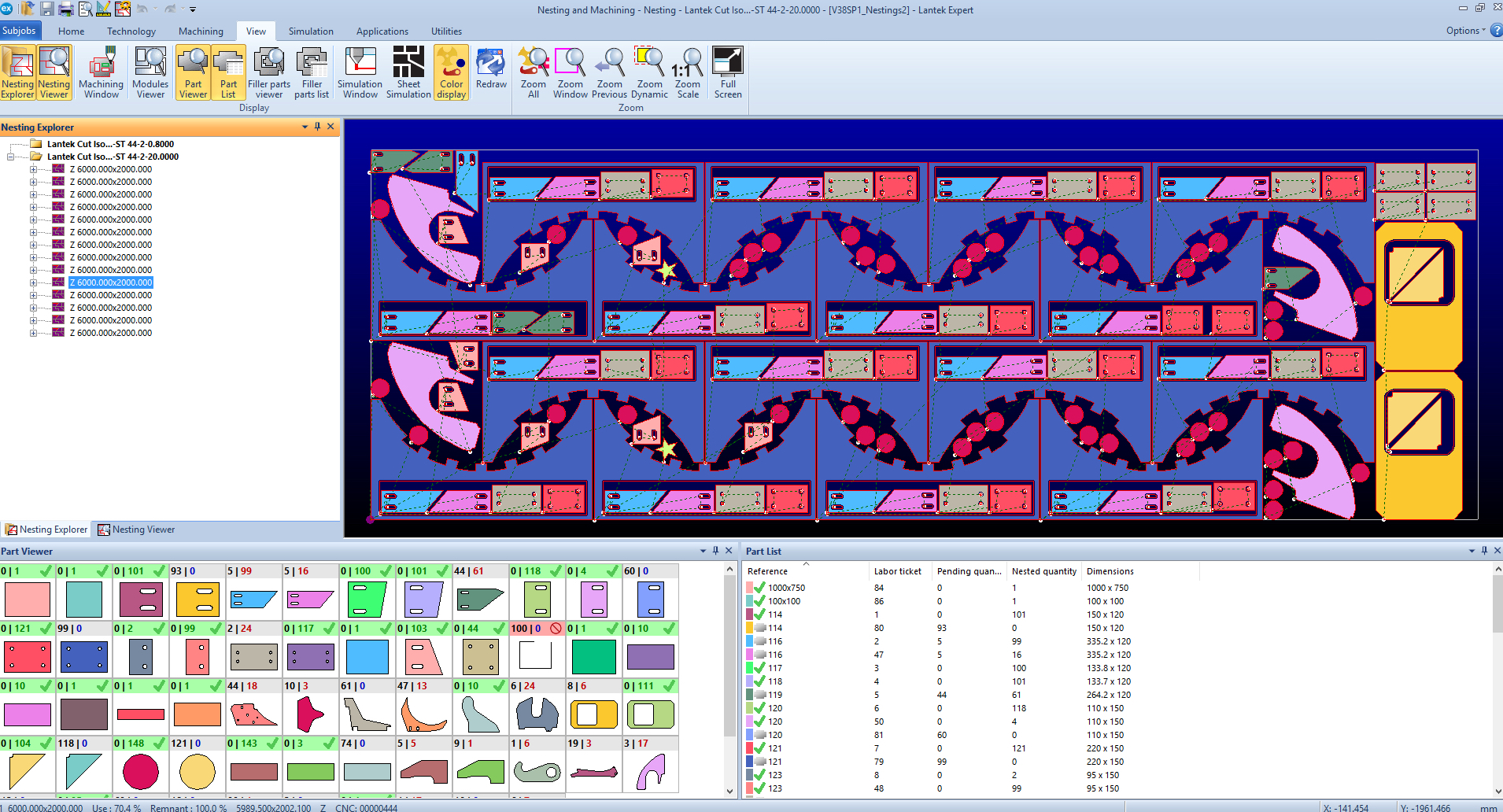

“What users often don’t realize is that to harness the full potential of a plasma source, you need powerful software,” says Christoph Lenhard, Lantek sales manager for Germany, Austria and Switzerland. The machines, which manufacturers provide at the Kjellberg demo center in Finsterwalde to make cutting tests for interested parties, can be programmed there with software from Lantek.

The long-standing and trusting cooperation between the two companies since the end of the 1990s enables the IT specialist to support further developments in Kjellberg plasma technology with its software in a timely manner. Lenhard: “For optimal use of Q 4500 and the entire Q series, our developers have programmed a completely new gating type. It meets Kjellberg’s requirements for using the power source for the cutting qualities that are possible with it.”

Sheet metal fabricators using Lantek will also find Kjellberg’s technology tables in the 2023 software update. This makes it easier for them to commission the Q-series plasma sources and leads them more quickly to their goal: an optimum cutting result.

© Kjellberg

Lenhard: “As a provider of machine-independent software, our goal is to cooperate as well as possible with all manufacturers of components and machines in order to advance sheet metal production. This is because we always want to provide end customers with software that optimally supports them in the application of all technologies at their current level – be it oxyfuel, laser or waterjet technologies, punching, shearing or even the plasma technologies.”

To this end, the software house continuously updates its portfolio and releases an update once a year – like now at “Schweißen & Schneiden”, the world’s leading trade fair for joining, cutting and coating technology.

Web:

Hall 7, Booth 7B31 www.lanteksms.com

Hall 6, Booth 6B21 www.kjellberg.de