Company

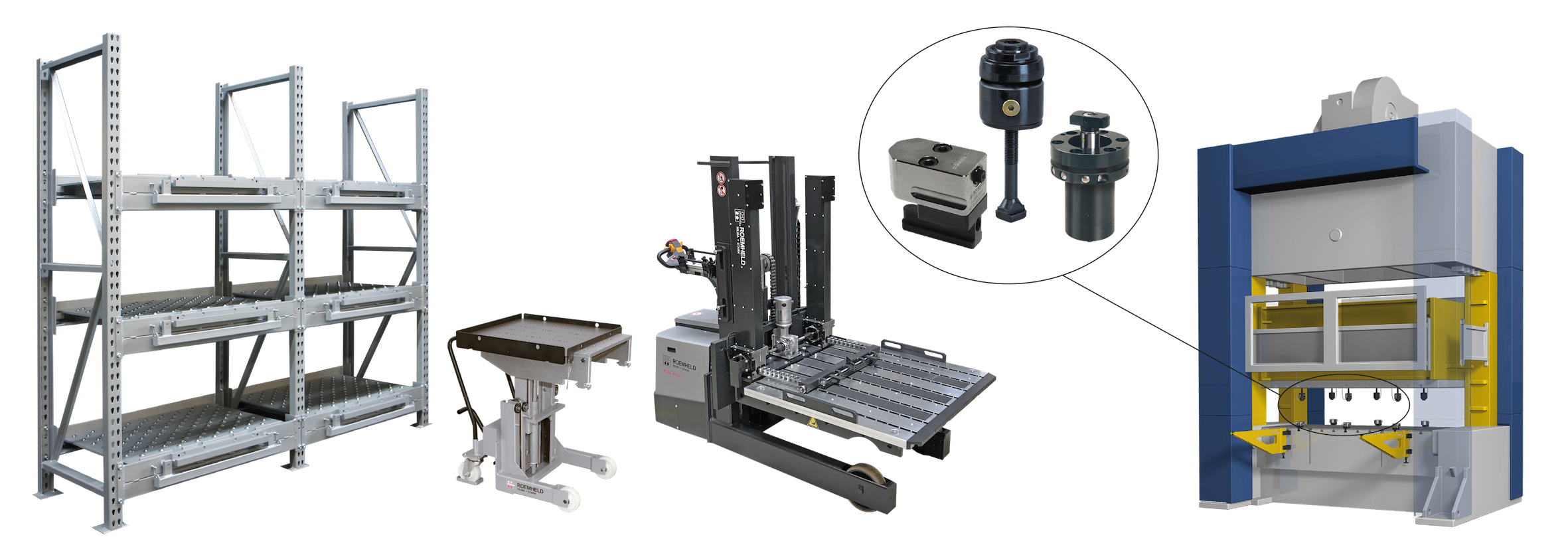

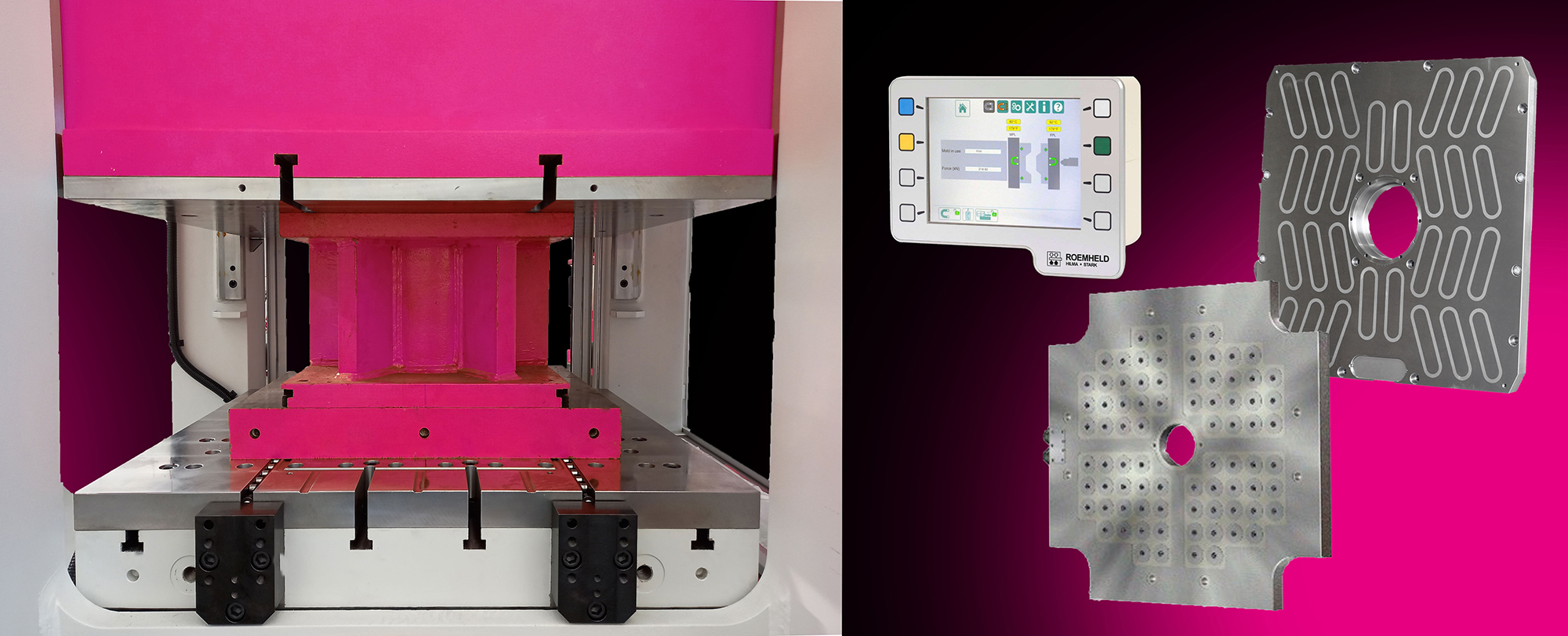

Tool handling with optimized set-up times and process reliability

At Blechexpo, Roemheld presented several innovations that help to reduce set-up times in sheet metal forming and increase operational reliability. R-Mag-M, the supplier’s first own magnetic clamping system for sheet […]