Short non-productive times are crucial for productivity in stamping and forming technology. The faster a mold change takes place, the faster the plant can continue production. At Blechexpo, Roemheld will therefore present a whole range of innovations for the efficient changeover process from a single source.

Roemheld innovations include new die change carts up to 6 t, a rail-guided platform cart for dies up to 40 t, new robust sheet clamps for straight clamping edges with locking device, and hollow piston cylinders that compensate for different clamping heights. The innovations, a new clamping technology app for tool clamping, a comprehensive overview of its program as well as exemplary complete offers for tool changing will be presented by the setup time optimizer in Hall 8 at Booth 8505.

A wide range of solutions

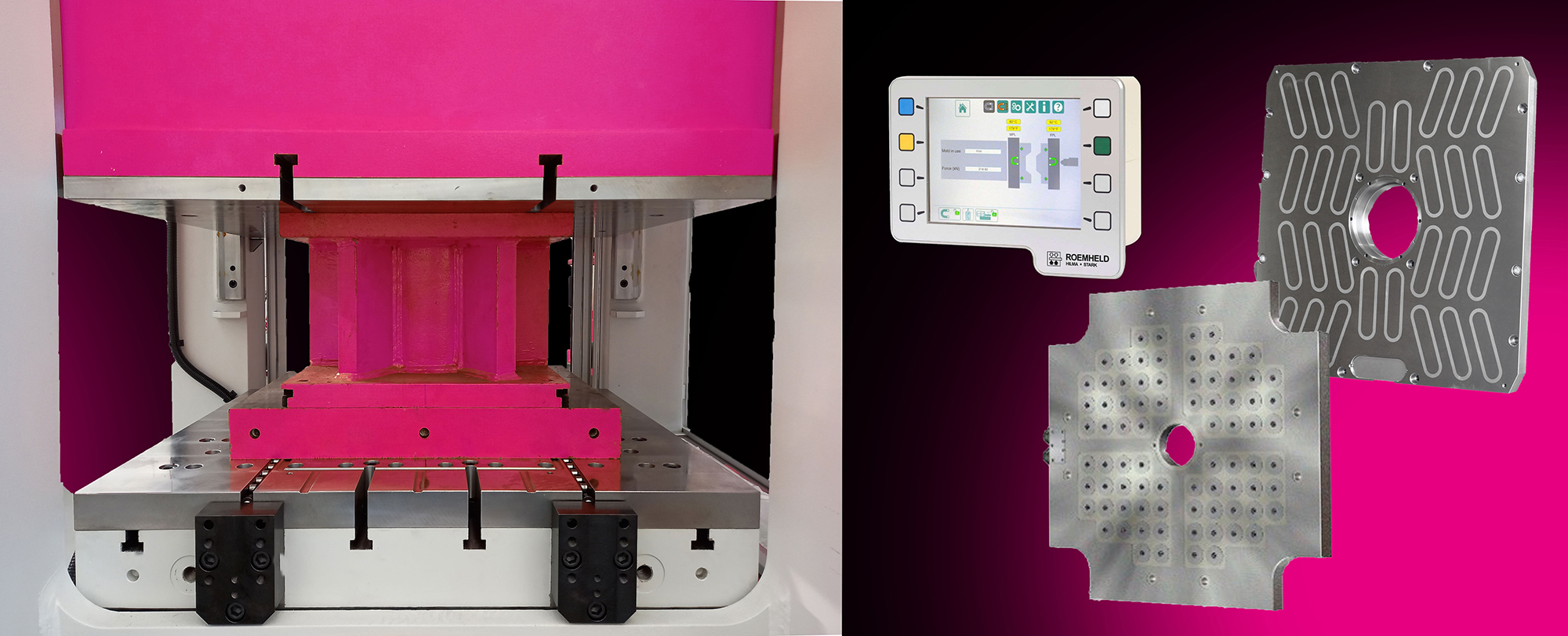

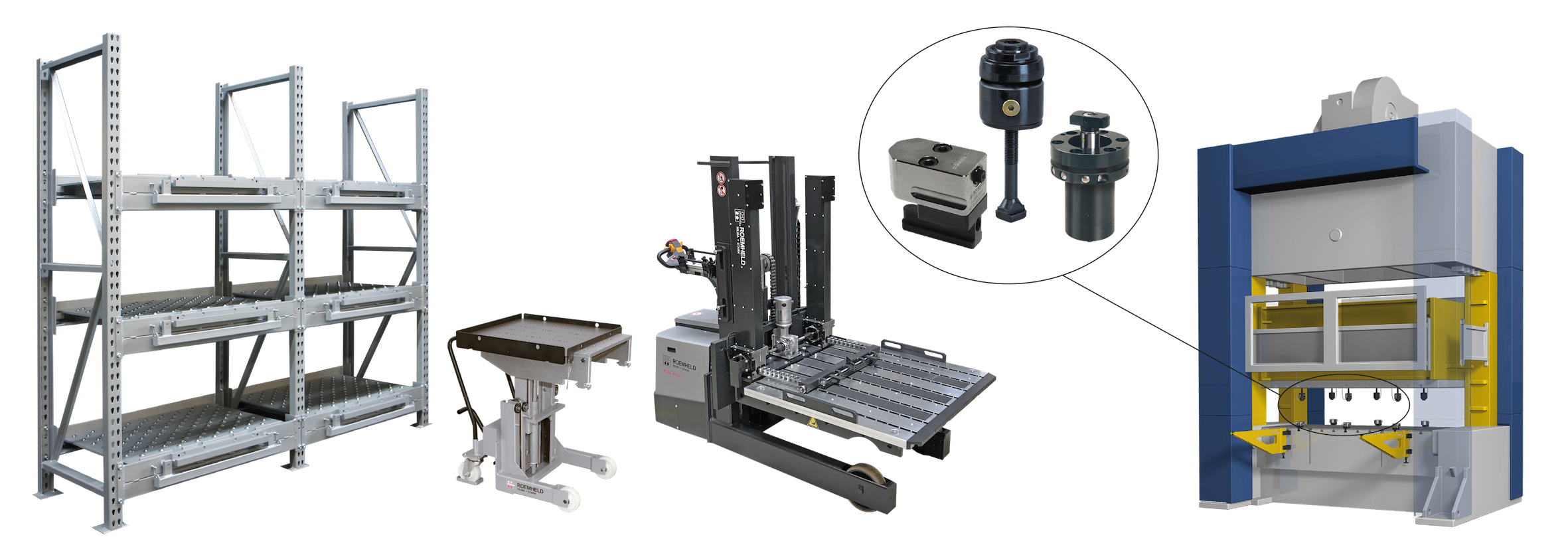

The solutions Roemheld offers are as diverse as the customers’ tool handling requirements. For one company, the focus is on the professional and safe storage of tools with racking systems. The next plant wants to implement improvements in transport or feeding to the press. For the third user, the focus is on positioning and fast and reliable clamping in the machine. Depending on customer requirements and the desired degree of automation, Roemheld offers different clamping elements for this purpose: magnetic, hydraulic, electromechanical or purely mechanical.

Transport tools weighing up to 40 t

Roemheld has added the RWA 2500 and RWA 6000 models to its range of tool changing carts. They offer a load capacity of up to 2.5 and 6 t, respectively, and feature a die changing table with integrated hydraulic ball rails and additional pull-push system that facilitate automatic insertion of the dies onto the press table.

During transport, the hydraulic balls in the table of the change cart are lowered, the tool is secured against slipping. A safety circuit ensures that the models only run when the ball bars are lowered.

For heavier tool weights, a platform truck with a load capacity of up to 10 t is now available. Thanks to its low lifting height, it can be moved freely, comes with a small height adjustment, offers a pull-push chain and is available with different platform sizes.

Trade fair premiere of rail-guided platform trolley

Loads of up to 40 t can be transported with the help of a rail-guided platform truck, which is making its debut at Blechexpo. Roemheld developed the innovation together with a transport and handling expert from Lower Saxony. It is available on the market in three versions with capacities for 15 t, 25 t and 40 t.

Moving on round rails results in extremely low rolling resistance, so that loads of up to 5 t can be shifted manually. Molds can be moved effortlessly on the carriage table via integrated roller bars by means of push chains, and bridging tables and pre-equipment stations facilitate insertion into the machine.

Innovations for tool clamping

Also on display at Blechexpo will be pull-push chain systems at the Roemheld booth. They are mounted directly on the machine and shift mold weights up to 40 t.

Sheet clamps ensure safe clamping of the molds

For safe clamping of dies in the press and die cutter, Roemheld presents new robust sheet clamps for straight clamping edges with locking device. As their clamping bolts move in an arc, there is no mechanical frictional locking, but increased safety thanks to an integrated mechanical interlock. Also new are hollow piston cylinders that can be used to compensate for different clamping rim heights of up to 30 mm.

New tool app

The company is also presenting a new web app for mold clamping and changing technology, which allows customers to select numerous products themselves. In addition to animations and technical data sheets, a gallery of application photos makes it easier to understand the information. Various checklists and selection aids support the user in choosing the right products.

Web:

wz-app.roemheld.de

BlechExpo:

Hall 8, Booth 8505