Many companies complain about the lack of skilled workers. RAS has prevented this by integrating the Bendex software into the Turbo2plus. The software automatically programs the bent parts, evaluates alternative bending strategies and, if required, shows the subsequent bending sequence on the screen. If you want to program the bent parts in the office, you can use the office software and send the programs directly to the machine.

The RAS swivel bending machine Turbo2plus is available for 3200 x 2 mm sheet steel and also for 2540 x 2.5 mm. A 4060 mm model will follow shortly. In addition to the pointing tool, a sophisticated tool system allows the production of cassettes up to 145 mm deep. These tools are available in two versions: with a large clearance in front of the tool for inward projecting bending legs or with a large clearance behind the tool for narrow and slim bending parts.

The tool segments are fixed in the upper beam with a quick clamping system, resulting in very short set-up times. A large 24″ touch monitor hangs on a swivel arm. It shows the operator which tool shape and which segments are required at which point along the working length of the machine.

Always on the safe side

A sensor system detects the current tool height in use and can distinguish whether the pointed tools or higher upper cheek tools are in use. This system increases the safety for operator and machine according to the current safety guidelines.

As soon as the operator starts a bending program, the servo backgauge positions the workpiece on the bending line. The particularly solid stop fingers position the sheet within the standard backgauge depth of 6 to 1550 mm. For large bent parts, the stop fingers can be extended in the middle area (T-stop) up to 3050 mm.

For small parts and profiles, the machine operator works on the bending beam side. If he swivels the control to the back of the machine and works from the stop side, he can bend even large and heavy housings effortlessly on his own. All stop fingers disappear under the table level when the bent part has to be rotated on the hold-up system. This ensures fast positioning and repeatably accurate bent parts.

The deep bending beam of the Turbo2plus is a prime example of superior engineering. Fast movement sequences ensure high productivity. Thanks to the automatic bending beam adjustment, the machine is always set to the current sheet thickness and achieves excellent bending results.

The top cheek closes and opens with impressive speed. With programmable opening and closing heights, the machine produces open and closed envelopes that make a bent part stiffer and more versatile.

The Turbo2plus swing bending machine is ideal for bending cassettes, boxes, panels and profiles made of thin sheet metal, such as those used by plumbers, in air duct construction, in advertising technology and in many other industrial sectors.

Bendex OpenEditor

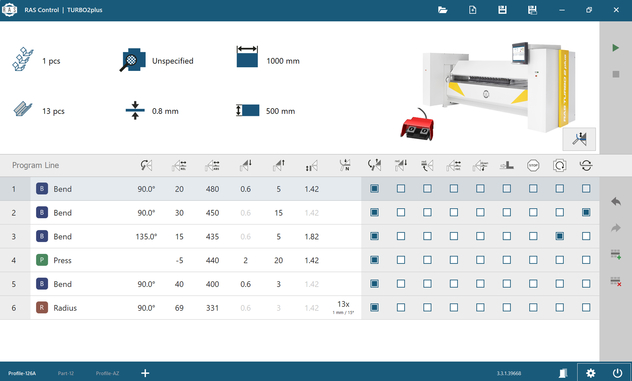

RAS extends the Bendex control system on the Turbo2plus swivel bending machines with the OpenEditor. With this type of input, operators at the machine can control each machine movement individually and program bending sequences entirely according to their preferences.

Up to now, the focus of the developers was mainly on the graphics functions of the Bendex controller. In the craft environment, however, it became apparent that some bending is also quite unconventional. Sometimes tension is applied to open envelopes and then bent with the upper cheek not quite closed.

In other cases, users have become accustomed to very specific bending sequences. Although the graphic control offers a feasible and reasonable bending sequence, the machine operators prefer to bend the profiles in the usual sequence.

With the addition of OpenEditor programming, both ways of working are now possible. Less experienced users can draw the desired profile on the touch monitor and the Bendex software programs the bending sequence automatically.

If several bending sequences are possible, Bendex evaluates the alternatives with a 5-star ranking. The favored variant with the most stars is at the top, followed by the other possible expirations. If desired, the graphic shows the sequence on the machine in a 3D simulation before the operator starts the bending process.

© RAS Sindelfingen

The programs can be saved and called up again later, for example, if a job in progress has to be interrupted by a quick shot or if a profile that was damaged on the construction site has to be remade.

In OpenEditor programming, the operator takes complete control and determines the sequence of bends by his input. This allows specialists to program exactly the processes they are familiar with. On a 24″ touch monitor with large input fields, even employees who are less familiar with controls can place their entries accurately. In each line, you can choose whether you want to perform a normal bend, close an envelope or create a radius from many single steps. If desired, display functions such as rotating and turning the bent parts, lowering the stop fingers and similar program functions can be anchored in the program.

Even with the OpenEditor, the user does not have to do without helpful functions. For example, material tables are available that correct the entered angles for the springback of the material depending on the selected material type, bending length and sheet thickness. The tools used can also be selected for automatic height detection. This safety function protects the machine when different tool heights are used on the machine. Based on the sheet thickness and the tools used, the software also calculates the setting height of the bending beam.

During the program sequence, the Turbo2plus then automatically adjusts the bending beam to this position. It is also possible to save programs. Saved programs are visible in the footer, so you can quickly jump from one program to the next.

With the OpenEditor RAS extends the way of programming a Turbo2plus swivel bending machine. As the saying goes, many roads lead to a destination.

Web:

www.ras-online.de