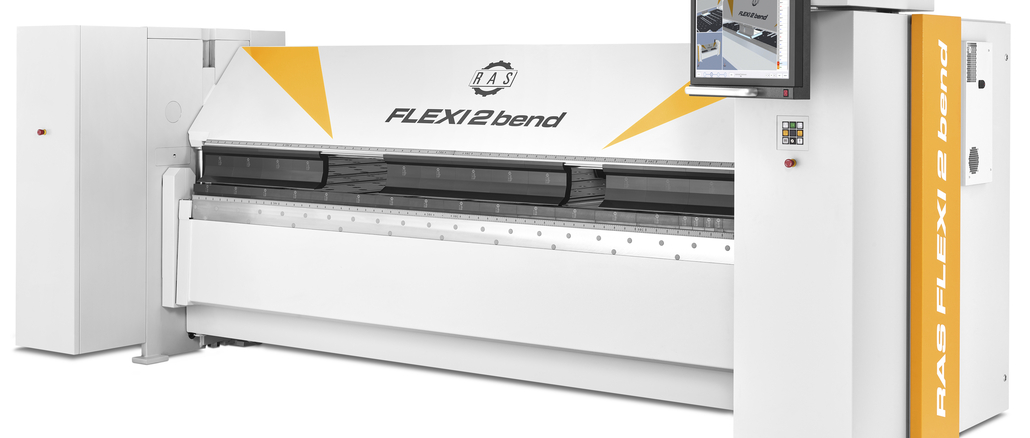

According to RAS, the Flexi2bend swivel bending system can be used to produce almost any swivel bent parts. It is thus a prime example of flexibility. The Flexi2bend bends complex bent parts with high added value just as precisely and repeatedly as simple cassettes, panels or profiles. The Bendex software programs the bent parts automatically. This can be done at the machine or already in the office. The software evaluates different bending strategies and shows the bending process in 3D on the monitor.

The RAS Flexi2bend swivel bending machine is available in the model sizes for 3200 mm x 3 mm and for 4060 mm x 2.5 mm. To ensure that the investment pays off quickly, the Flexi2bend shines with high speeds of the highly dynamic servo axes. The result is a higher throughput.

The Bendex software runs directly on the machine controller. The software creates the bending programs with a single mouse click, starting from profiles drawn on the screen or imported bending part graphics. These can be step, dxf, dwg or geo files. The programs can be generated on the machine or in the office.

In order for the software to create the programs with the real machine data, the current machine parameters are loaded into the office software via data line. This also takes into account, for example, the tools actually available on the machine. The bending sequences created can be viewed in advance in a 3D simulation and, if necessary, the user can also intervene in the sequence. The simple operation reduces the training time to a minimum.

However, the machine’s flexibility is not only evident when it comes to fast programming, but also when preparing the machine for the next job. As soon as the sheet thickness changes, the bending beam and lower beam automatically adjust to the new sheet thickness within seconds. This guarantees the highest quality in terms of bending radius and ensures the longevity of the machine.

The Flexi2bend also offers maximum convenience during set-up. The tools of the upper beam and bending beam are simply inserted into the tool holder and automatically clamped when the machine is switched on. A setup guide automatically programs the Bendex software and graphically displays it in individual changeover steps on the 24″ touch monitor. Tool segments that are not currently required can be stored in a lockable storage compartment that is integrated into the side paneling of the machine.

Special tools

Although a single tool set is often sufficient for the entire part spectrum in swivel bending, RAS offers a variety of tools for different tasks. The tools are available with a tool tip or with a radius. Such radius tools are mainly used when bending thicker aluminium sheets or colour-coated metal, so that there is no cracking of the surface or colour changes at the bending edges.

In addition to the pointing tool, a wide range of segmented tools are available. These tools are available in two versions: with a large clearance in front of the tool for inward projecting bending legs or with a large clearance behind the tool for narrow and slim bending parts. The machine’s sensor system automatically detects the tool height used. This system increases the safety for operator and machine according to the current safety guidelines.

Even more flexibility is offered by the standard split bending beam tools. They allow the bending of offset and interrupted bending lines or of bends in the inner area of the blank.

The special RAS tools further expand the range of applications for the Flexibend. The SnapTool corner pieces with hinged sole automatically emerge from bending parts with lateral legs. The tool sole folds down when the upper beam is opened and snaps back into the working position as soon as the tools have moved out of the bent part. Manual unscrewing of the bent parts at the end of the bending cycle is therefore not necessary.

With the DownTools in the bending beam, interrupted edges can be bent without additional tooling. Examples of use are gills, angled bent parts, inwardly bent legs, interrupted bending lines and protruding lugs.

As soon as the operator starts a bending program, the servo backgauge positions the workpiece on the bending line. The particularly solid stop fingers position the sheet within the rectangular stop depth of 10 to 1550 mm. For large bent parts, the stop fingers can be extended in the middle area (T-stop) up to 3050/4060 mm. When bending smaller parts and profiles, the machine operator works on the bending beam side. If he swivels the control to the back of the machine and works from the stop side, he can bend even large and heavy housings effortlessly on his own. All pop-up stop fingers disappear under the table level when the bending part has to be rotated on the hold-up system. This ensures fast positioning and repeatably accurate bent parts.

The intelligent crowning system automatically compensates for the deflection of the bending beam in the case of thick sheets and thus ensures dead-straight bends. The operator does not have to enter any crowning values when bending thin or thick sheets, processing sheet steel or stainless steel, or forming long or short legs. Instead, the software automatically determines the appropriate crowning setting. The automatic adjustment has a nice additional effect. If the crowning is lowered completely in the program sequence and the bending beam is swivelled to 90 degrees, the bending beam can also be used as a front stop for angled blanks, for example.

The top cheek closes and opens with impressive speed. With programmable opening and closing heights, the machine produces open and closed envelopes that make a bent part stiffer and more versatile. The upper beam can also open while the bending beam is still swinging down. This Speed Optimizer function noticeably increases the speed of the bending process.