Turkish automotive supplier AK-Pres Automotive, founded in 1990 and part of Küçükoğlu Holding, invested in a 16,000-kilonewton machine including automation. This is the first servo transfer press that Schuler has supplied to Turkey.

The servo transfer press type TSD is suitable for processing high-strength steels, as they are usually used in lightweight construction. Thanks to the operator-programmable slide kinematics and the possibility of briefly stopping the movement of the upper die for additional functions, processes such as welding and lasering can also be reliably integrated into the forming process.

The TSD 1600 delivered to AK-Pres is supplied with a table length of 6,100 mm and a table width of 2,500 mm. Productivity can reach 40 strokes per minute, depending on the programmed lift height and kinematics. In addition, the pendulum stroke offers flexibility in press speed and die opening.

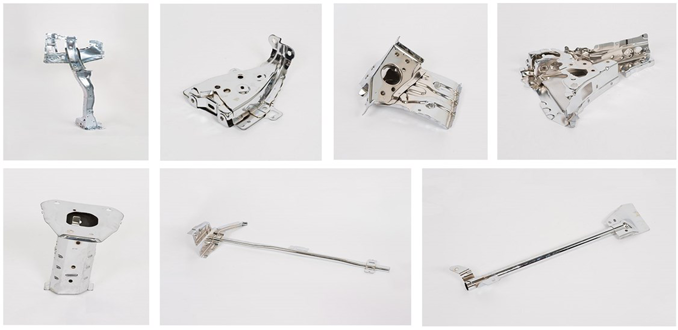

Schuler’s TSD series can process a wide variety of parts and materials, from simple stampings to highly complex structural parts. The user interface developed by Schuler includes a curve generator, the “Optimizer”, which carefully matches the slide kinematics and automation parameters to ensure high process reliability. The tryout functions with a handwheel and intelligent tool change systems with semi- or fully automatic tool change lead to short set-up and changeover times.