Polyrix, manufacturer of innovative measurement solutions for industrial manufacturing companies, now offers its product range in Germany and other European countries.

© Polyrix

“With Herbert Daxauer and Axel Bleifuß from A&B KMG Service GmbH, we were able to gain competent experts for these markets who together have more than 50 years of sales and service experience with leading metrology manufacturers such as Faro, Hexagon, Steinbichler Optotechnik, Wenzel or Zeiss,” reports Jonathan Bouchard, Director Sales and Business Development at Polyrix. “In addition, we have opened a demo center in Ergolding near Landshut in Bavaria, i.e. not far from Munich Airport, where we professionally present the performance of the PolyScan system to interested parties. We also conduct user training at this location.”

Polyrix was founded in 2005 by researchers at the Computer Vision and System Laboratory at Laval University in Quebec City, Canada. Based on the knowledge gained from cutting-edge 3D research, the team recognized the need for fast and easy 3D scanners for inspections. Today, Polyrix customers include well-known companies such as Boeing, Bosch Rexroth, Schneider Electric and Stellantis.

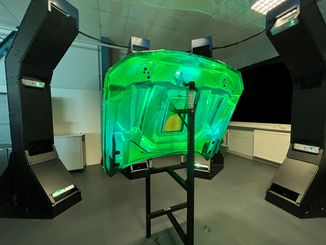

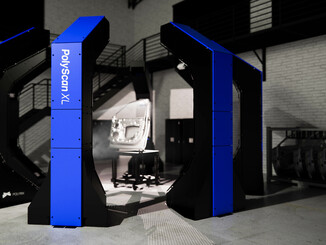

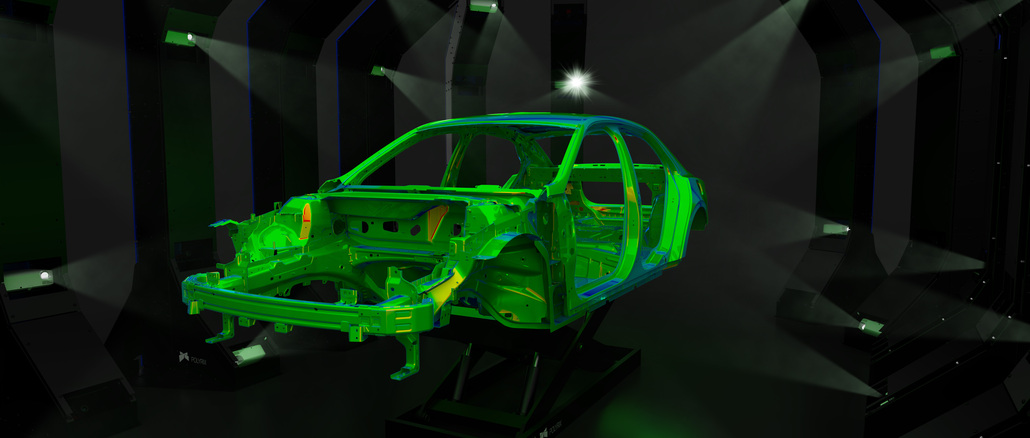

Polyrix measurement solutions enable industrial manufacturing companies to automate inspection processes in a simple, efficient and safe way. PolyScan Surround 3D scanners are available in a variety of sizes and configurations. They allow complete coverage with one scan in one shot – from a tiny turbine blade to an entire vehicle. Deviations are projected directly onto the part by the surround arrangement of the high-resolution projectors. With this technology, users can change color maps and receive dynamic, intuitive feedback at the touch of a button.

Typical applications of the 3D measuring system are in particular dimensional inspection, in-process quality assurance and the inspection of components, tools and models. “For these measurement tasks, the PolyScan scanner is used quickly, easily and reliably – in other words, exactly as practitioners rightly demand and expect. This is another reason why we see great potential for Polyrix scanners in Germany,” emphasizes Herbert Daxauer. “Especially since, in addition to the timely return on investment, 3D measurement systems offer several other key advantages: three to four times faster data acquisition compared to handheld and robotic scanners, the absence of complex software programs, as well as minimal fixturing and low maintenance costs.”

About Polyrix

Founded in 2005, Polyrix Inc. has its headquarters in Saint-Augustin-de-Desmaures (Quebec), Canada. The company offers measurement solutions for industrial production that automate testing processes simply, efficiently and in a safe manner. The PolyScan Surround 3D scanners are primarily used in applications such as dimensional inspection, in-process quality assurance and the inspection of components, tools and models. In the course of this, the 3D measuring systems are particularly convincing due to their fast return on investment, rapid data acquisition and low maintenance costs. Polyrix’s reference customers include renowned companies such as Bell, Boeing, Bosch Rexroth, Collins Aerospace, Ford, Pratt & Whitney, Schneider Electric and Stellantis.

Web:

www.polyrix.com