If it’s up to the TV people, the Rosenheim area is an extremely dangerous place, with about 40 murders a year. The reality is not quite as bad. Hanselko GmbH is actually doing very well in nearby Raubling, mainly because it is investing in the right equipment.

Hanselko GmbH was founded in Rosenheim as early as 1989. Today, 33 years later, the service provider in the fields of trade fairs and digitization has not only moved its headquarters to nearby Raubling, but has also had a second location in the Lower Bavarian capital of Landshut since 2002. Hanselko’s broad range of services and know-how has also expanded in the meantime: it includes virtual feature planning and measurement data management, optical and tactile 3D measurement services on mobile as well as stationary devices, optical digitization/reverse engineering, offline programming of 3D CNC coordinate measuring machines as well as consulting and method-oriented training.

The service provider’s reference list of renowned customers, not least from the automotive industry, is also impressive. Hanselko offers these companies a wide range of measurement equipment, especially for mobile, optical measurements.

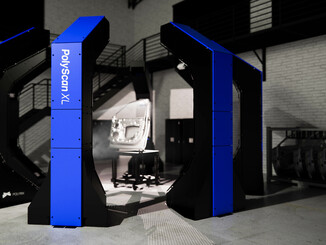

© Polyrix

Since 2021, the service provider has also had the innovative PolyScan surround 3D scanner from Polyrix. PolyScan offers Hanselko and the customers decisive advantages, because the system works quickly, easily and safely. The Surround 3D Scanner is primarily used for dimensional inspection, in-process quality assurance and the inspection of components, tools and models.

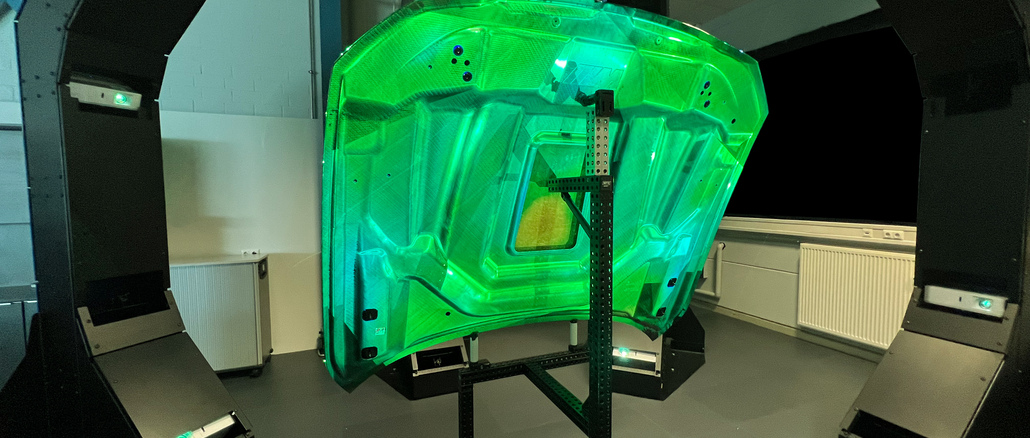

Just recently, PolyScan also impressed the specialists at the BMW Group. For them, Hanselko carried out a full-surface digitization of a CFRP front flap in Landshut with subsequent live inspection on the component. “We were the optimal partner for this order because we were able to carry out the measurements without any major preparation or programming time and without having to glue any marks. And because we already have a long-standing good business relationship with this customer,” emphasizes Managing Director Günther Hanselko. “Above all, however, with PolyScan we have the perfect system for full-area digitizing. Until now, by the way, the premium car manufacturer carried out the analysis of production quality with purely optical measurements.”

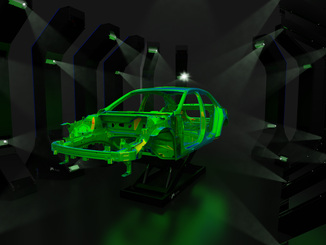

The direct integration of the PolyScan system into the inspection software enables simple and fast analysis of the component quality. The start of the measurement is enough to capture everything that is in the measurement field of the system.

In the course of this, the top and bottom sides were digitized in a single clamping operation for the BMW Group. The intelligent arrangement of the 16 projectors and 16 cameras supports the all-round detection of the component. There is no need for time-consuming repositioning of the component or the sensor.

In this measurement task, the Liveinspection feature in particular showed its strengths: Here, deviations are projected directly onto the respective measurement object by the surround arrangement of the high-resolution projectors. This technology enables the user to individually adjust the color-coded and component-related tolerance spectrum. He also receives dynamic and intuitive feedback at the touch of a button.

The issue of costs plays an essential role (not only) for a service provider. PolyScan Hanselko is also convincing at this point – and not only because of low maintenance costs due to the stationary (motion-free) arrangement of the sensor technology. In addition, however, the time benefits offered by the Surround 3D Scanner, for example through reduced preparation times and ease of operation, are also important for a service provider: “Especially since the Polyrix system captures millions of measuring points 3 to 4 times faster than handheld or robot scanners – and without user interaction. In addition, it is of great advantage to us that the creation of complex robot programs for automated scanning and their maintenance are no longer necessary and PolyScan only makes low demands on the fixture technology,” summarizes Co-Managing Director Robin Hanselko. “In the end, it is the overall package, including better analysis options and more visual reporting, with which PolyScan completely convinces us. By the way, it’s not just us – the acceptance of measurements with Polyrix is also growing among our customers.”

Web:

www.polyrix.com